Anti-explosion impact wave filtering valves

A shock filter and anti-explosion technology, which is applied in the field of anti-explosion valves, can solve the problems that the valve plate cannot quickly open the pipeline, affect the life safety of indoor personnel, and the transient performance of the valve plate is not high, so as to improve the sensitivity of feeling and eliminate Short circuit, responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

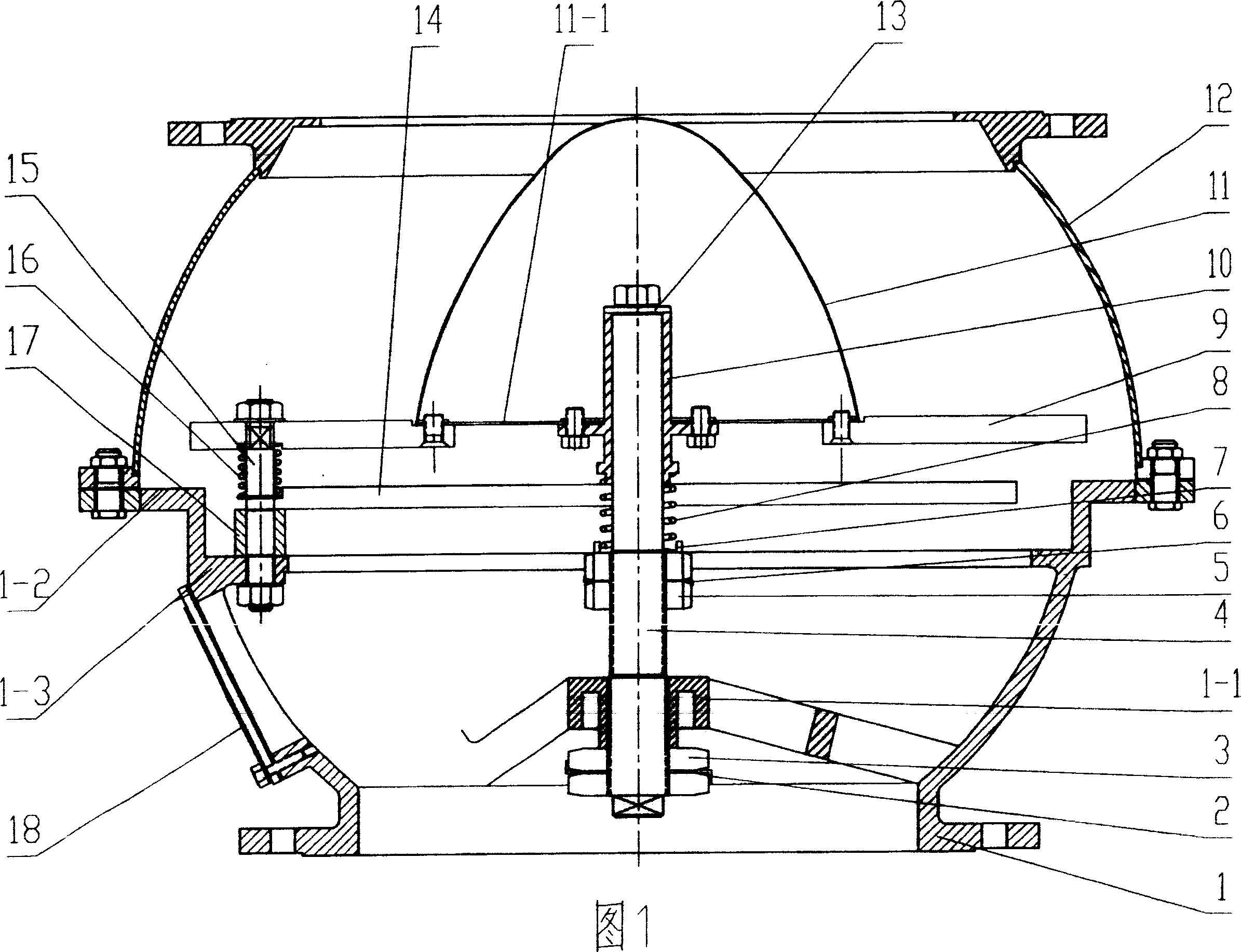

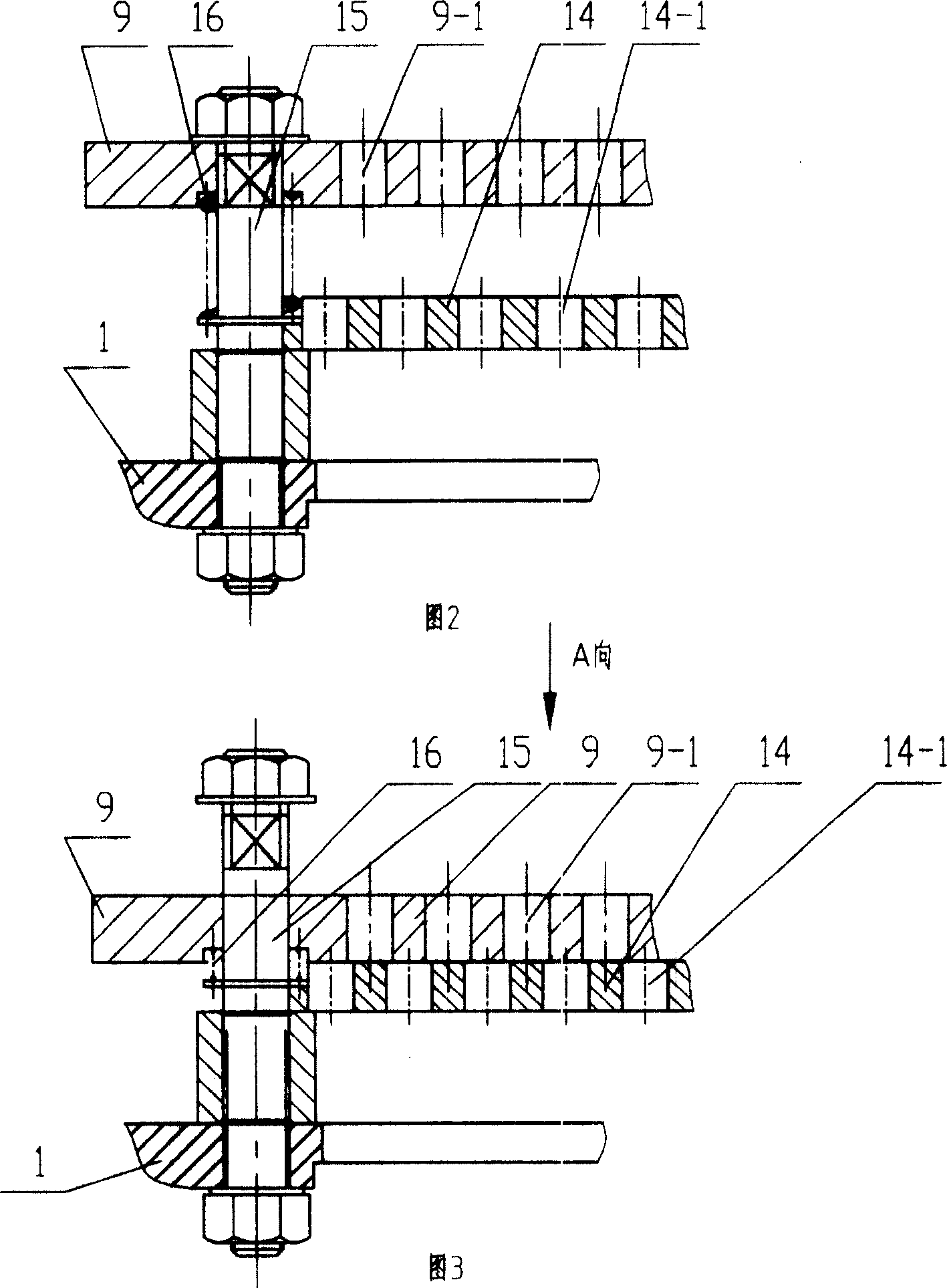

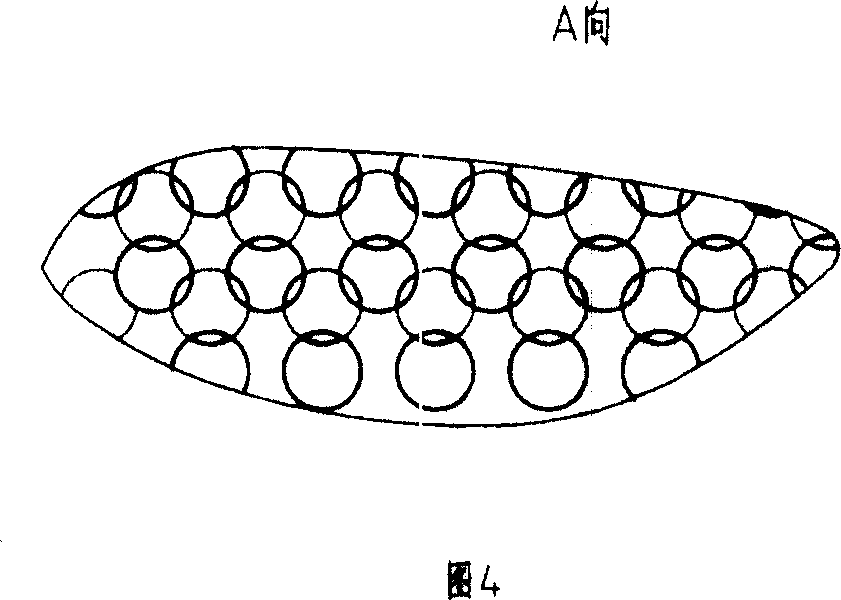

[0026] See the anti-explosion shock filter valve shown in Figures 1 to 4, including the front valve body 12, the rear valve body 1, the valve stem 4 and the valve plate 9, the cavities of the front valve body 12 and the rear valve body 1 are spherical, and both Made of metal material, the front valve body 12 and the rear valve body 1 are connected to the pipeline through their respective flanges, and the side of the rear valve body 1 has a window door 18 for easy adjustment. There is a valve seat 1-2 attached to the lower end surface of the valve plate 9 on the periphery of the rear valve body 1 front portion outside, and the valve stem 4 is connected on the support seat 1-1 of the rear valve body 1, and the valve seat 1-1 at the bottom of the support seat 1-1 The valve stem 4 is equipped with an adjusting piece that adjusts the distance between the valve plate 9 and the valve seat 1-2. The adjusting piece can use a commonly used nut 3, and lock the adjusted nut 3 through the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com