Burner assembly and method for combustion of gaseous or liquid fuel

A technology for burning gas and liquid fuel, which is applied in gas fuel burners, combustion methods, burners, etc., and can solve problems such as thermal damage to the combustion chamber wall and high NOx emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

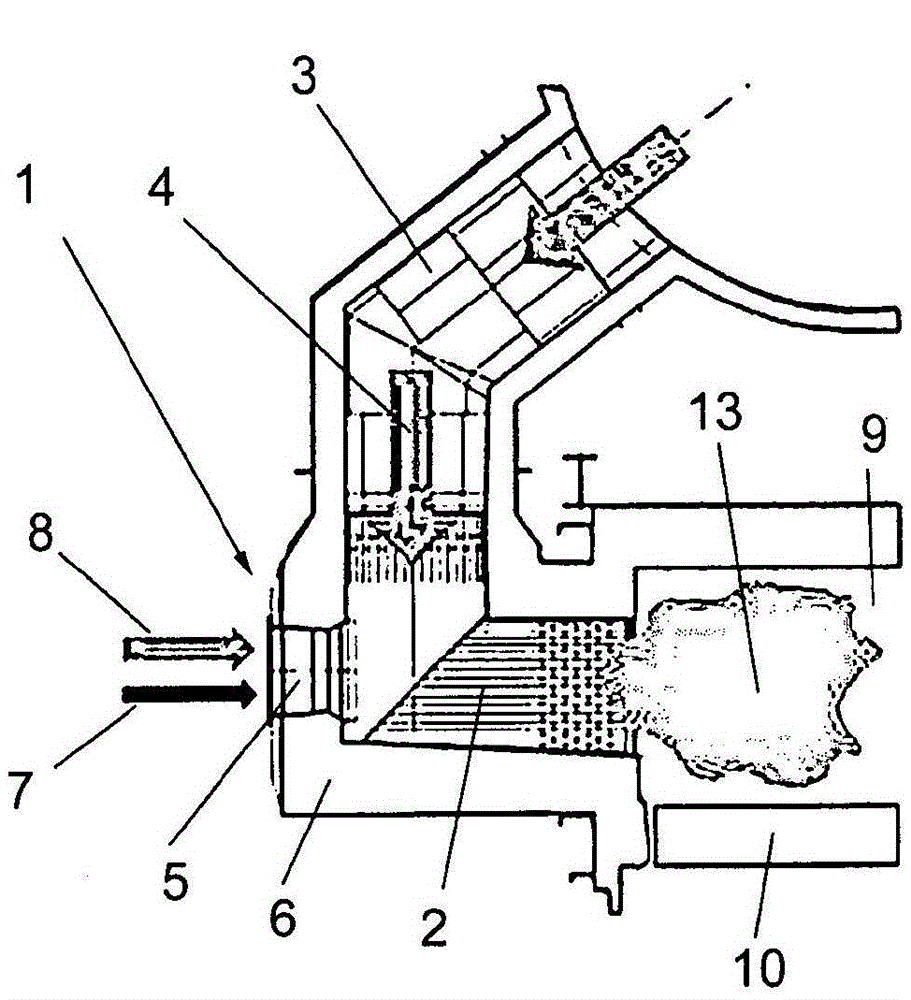

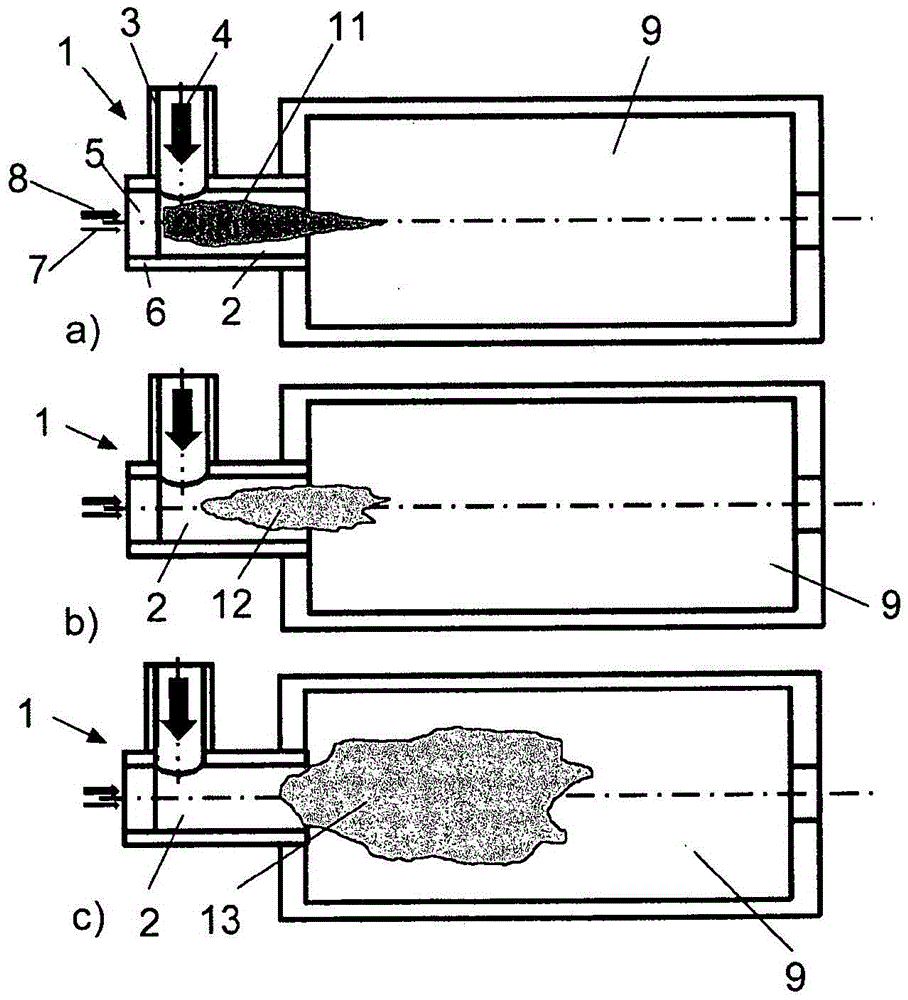

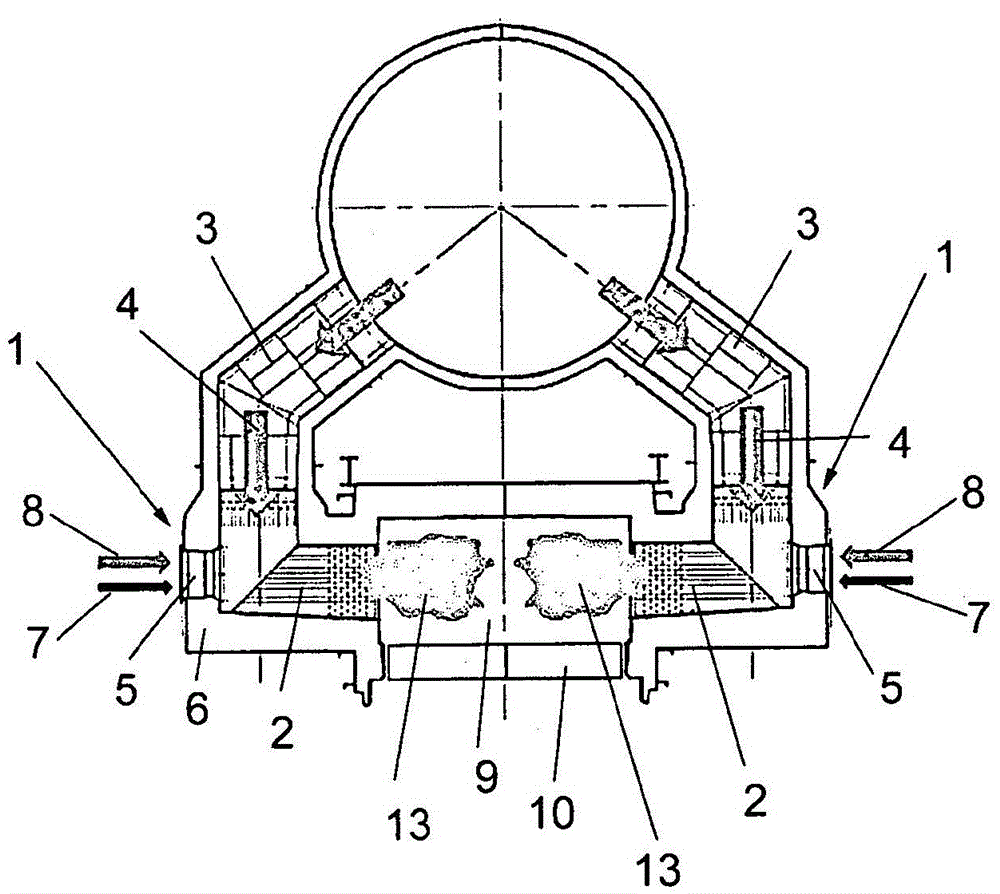

[0051] exist figure 1 In , a burner assembly 1 according to a preferred embodiment of the present invention is shown in cross-section. The burner assembly 1 has a combustion chamber 2, a main combustion air inlet 3 for feeding preheated combustion air 4 into the combustion chamber 2, and a burner 5 located in a wall 6 of the combustion chamber 2 so that through the main combustion The combustion air 4 which flows into the combustion chamber 2 through the air inlet 3 passes through the burner 5 . The burner 5 has at least one fuel supply pipe 7 and at least one air supply pipe 8 for respectively supplying fuel and primary air into the combustion chamber 2 . Furthermore, the burner 1 has a control unit or control device (not shown) for controlling the supply of fuel and primary air into the combustion chamber.

[0052] The combustion chamber 2 leads to an industrial furnace 9 where the desired treatment of the material takes place.

[0053] According to a preferred embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com