A spool spin passive control type solid-containing multiphase flow control valve

A multi-phase flow, spin-type technology, applied in the valve's device for absorbing fluid energy, lift valve, valve device, etc., can solve the problems of local abrasion, damage to valve trim, easy to block, etc., to prevent Deposit clogging, high service life, extended service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] For ease of understanding, the specific structure and working mode of the present invention are further described below:

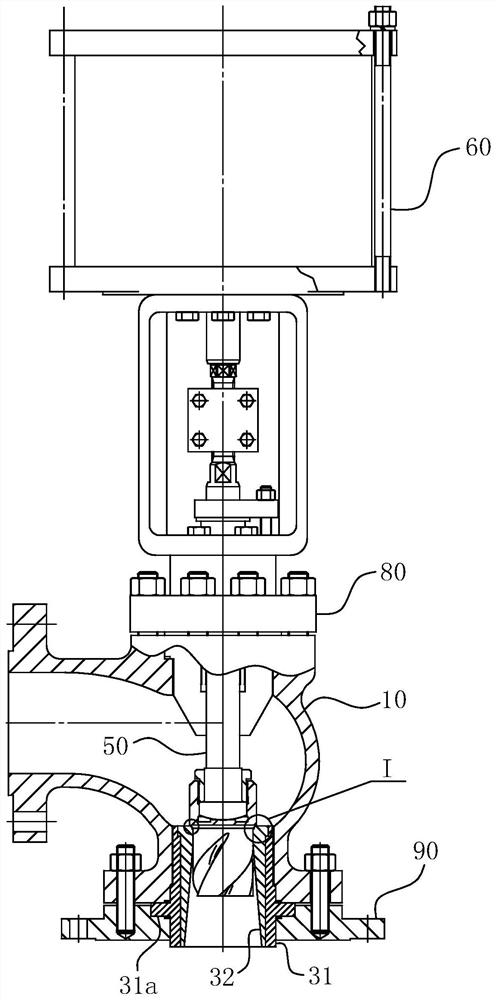

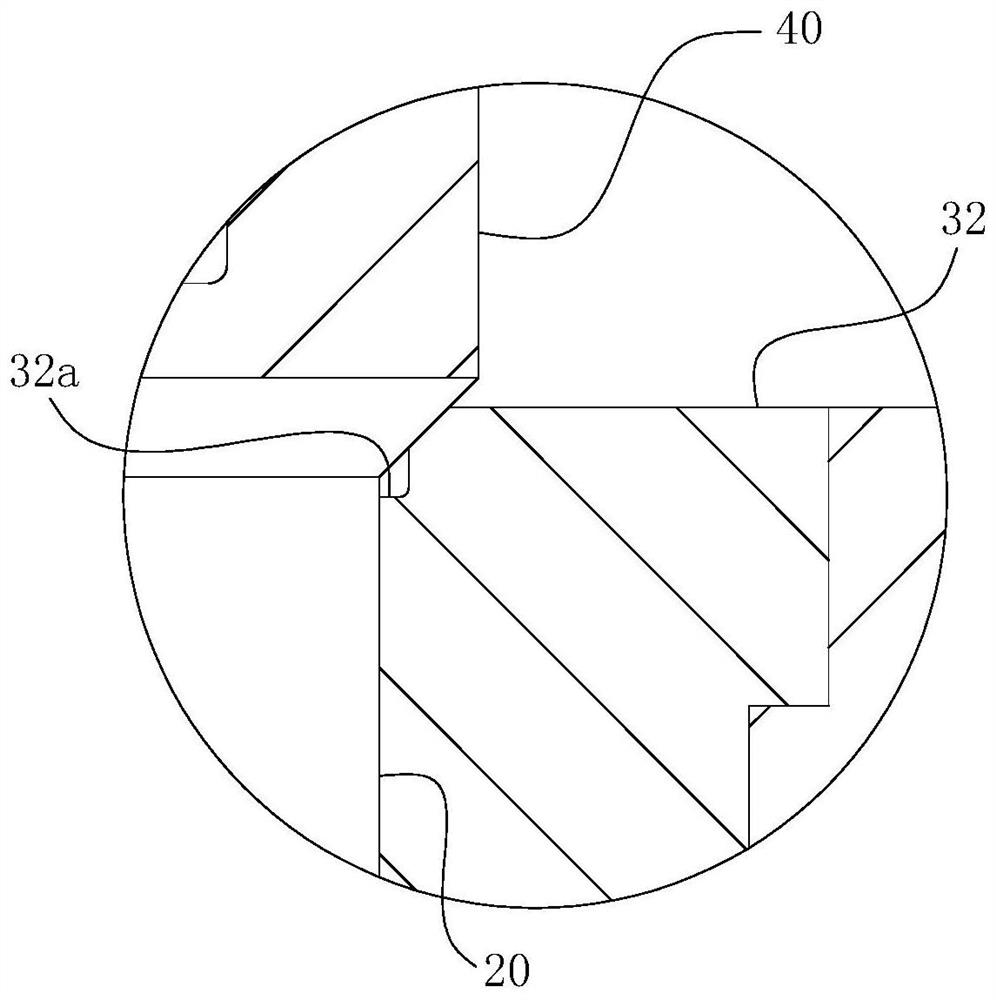

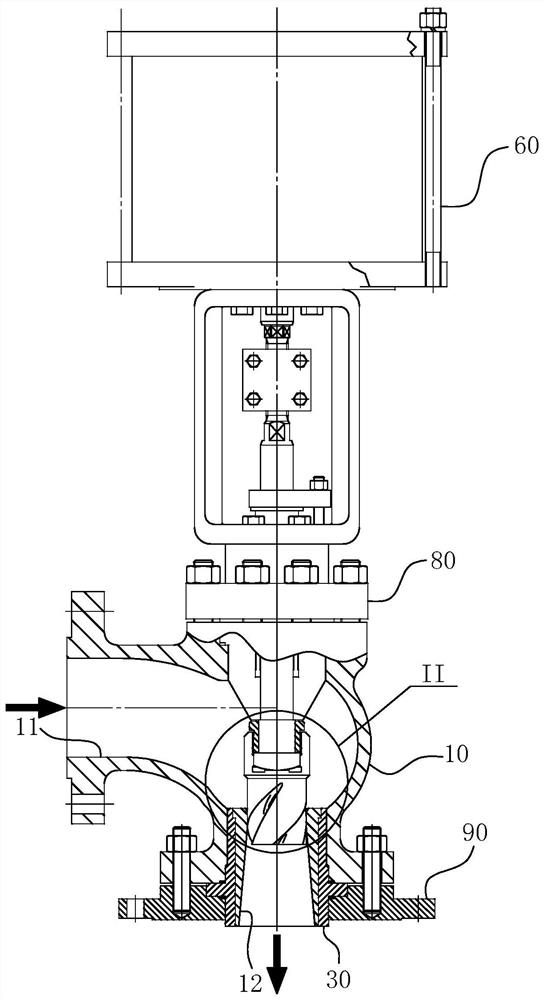

[0037] The specific implementation structure of the present invention can refer to Figure 1-8As shown, it mainly includes a valve body 10, a valve core 20, a valve seat 30, a valve stem 50, a driving source 60, a valve cover 80, and the like. in as Figure 1-4 In the shown structure, the outer wall of the valve core 20 cooperates with the cylindrical sealing surface formed in the sleeve cavity of the valve seat 30 , and the valve core 20 and the valve stem 50 are connected with the T-shaped head structure through the rotary sleeve 40 to form a rotary connection. In actual operation, the valve core 20 can freely rotate around itself or the axis of the valve seat 30 through the above-mentioned rotary connection.

[0038] More specifically, as figure 1 and image 3 As shown, the present invention sequentially arranges the drive source 60 , the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com