Water-cooling electric mold and preparation method thereof

An electric mold and water-cooling technology, applied in the field of smelting molds, can solve the problems of poor product quality and complex components, and achieve the effects of improving quality, reducing impurity content, and reducing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

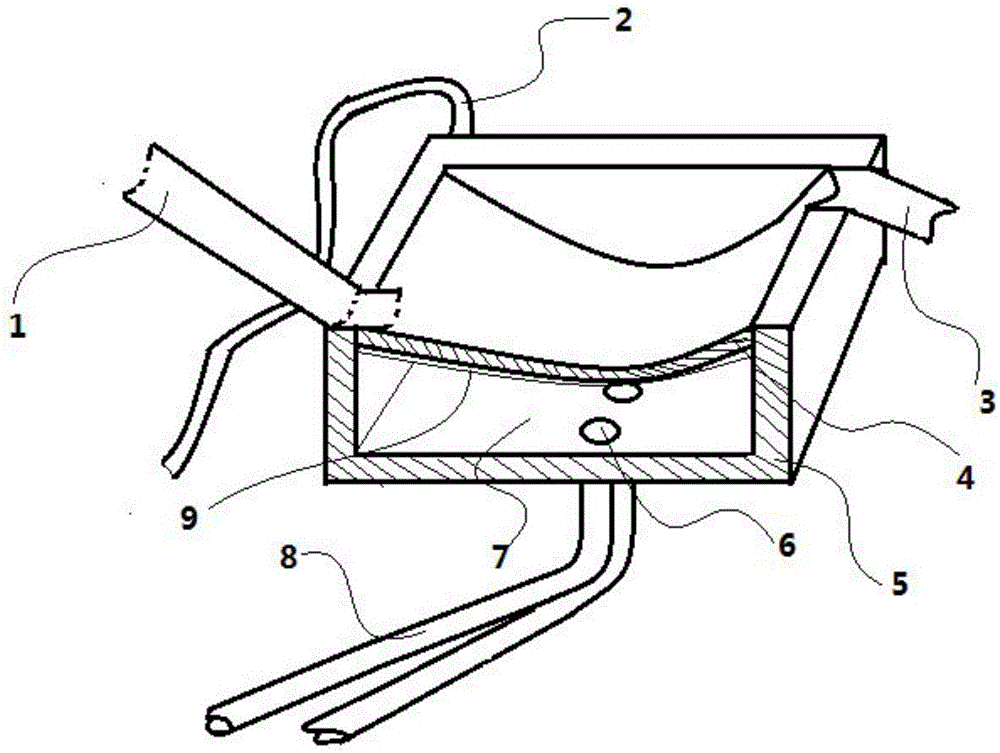

[0029] Such as figure 1 As shown, a water-cooled electric mold consists of a mold body 5, a cooling tank 4 arranged in the mold body 5, a water inlet 6 arranged at the bottom of the mold body 5, a water inlet pipe 8 communicated with the water inlet 6, and the mold body The upper end surface of 5 is connected to the smelting water inlet 1 that enters the cooling tank 4, the molten iron outlet 3 that is connected to the upper end surface of the mold body 5 and extends out of the mold body 5, and the water cavity 7 formed by the mold body 5 and the cooling tank 4 and set The outlet pipe 2 on the side of the mold body 5 is formed, and the mold body 5 is composed of a mold body wall and a mold bottom to form a polygonal groove.

[0030] The cooling groove 4 is a groove recessed toward the bottom of the mold body 5 .

[0031] The cooling groove 4 is a downwardly recessed groove, and the bottom of the groove forms an arc.

[0032] In the arc, the bottom end of the arc is close to ...

Embodiment 2

[0039] Such as figure 1 Shown, on the basis of embodiment 1, a kind of preparation method of water-cooled electric mold comprises the following steps:

[0040] (1) Formwork preparation: select an open space downstream of the smelting furnace, level the open space, and pour concrete on the ground to form a plane. After the concrete solidifies, obtain the formwork bottom; then use bricks to form the formwork wall , the formwork wall is built into a double-layer with a sandwich layer, and concrete is filled in the sandwich layer, and vibrating rods are used to vibrate and squeeze tightly. After the concrete in the sandwich layer is solidified, a water inlet is opened on the bottom of the formwork, and The steel pipe is inserted into the water inlet, the upper surface of the steel pipe exceeds the surface of the mold bottom by 5-10cm, the lower surface of the steel pipe penetrates the bottom surface of the mold bottom by 5-10cm, and then the yellow mud is spread on the upper surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com