A dampening machine capable of improving the uniformity of temperature and humidity of tobacco leaves and reducing crushing

A technology of increasing temperature, humidifying, and uniformity, which is applied in the fields of tobacco, tobacco preparation, and application. It can solve the problems of tobacco leaves being difficult to be heated, loose effect cannot be guaranteed, and the uniformity of moisture content of export materials is poor, so as to improve the comprehensive quality and The effect of processing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

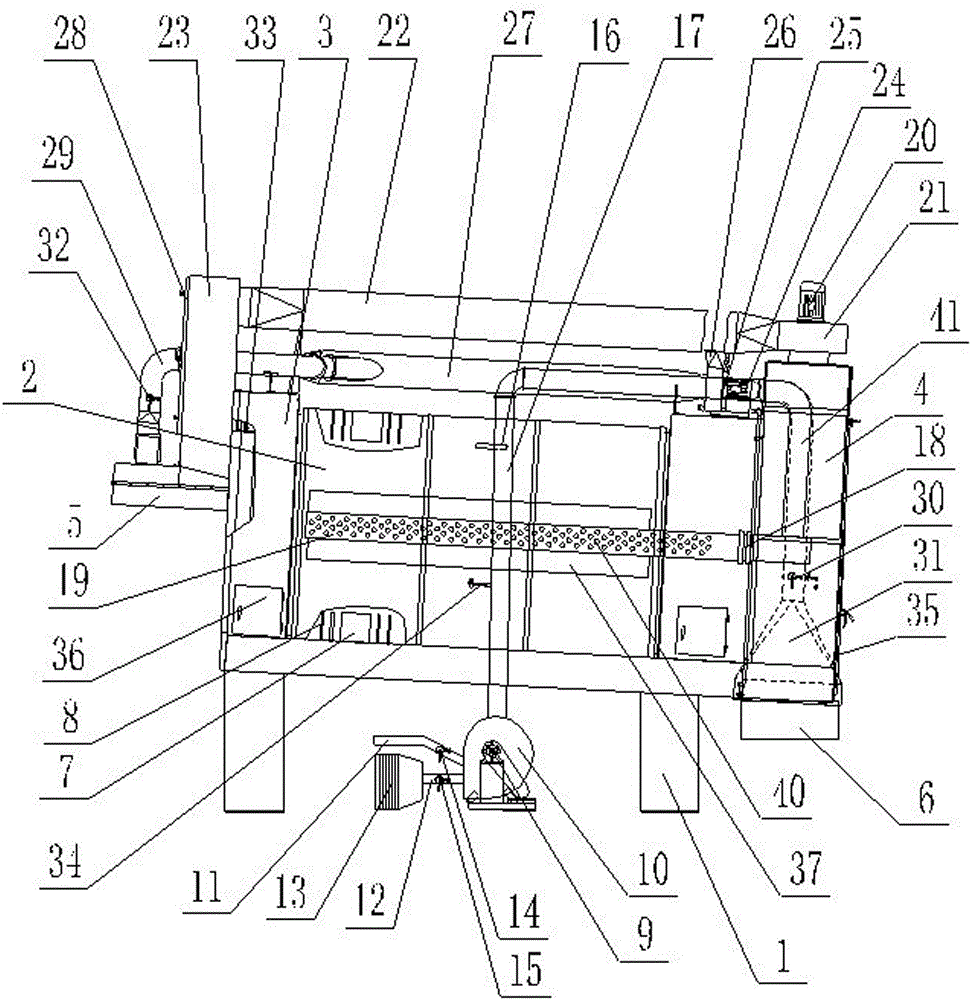

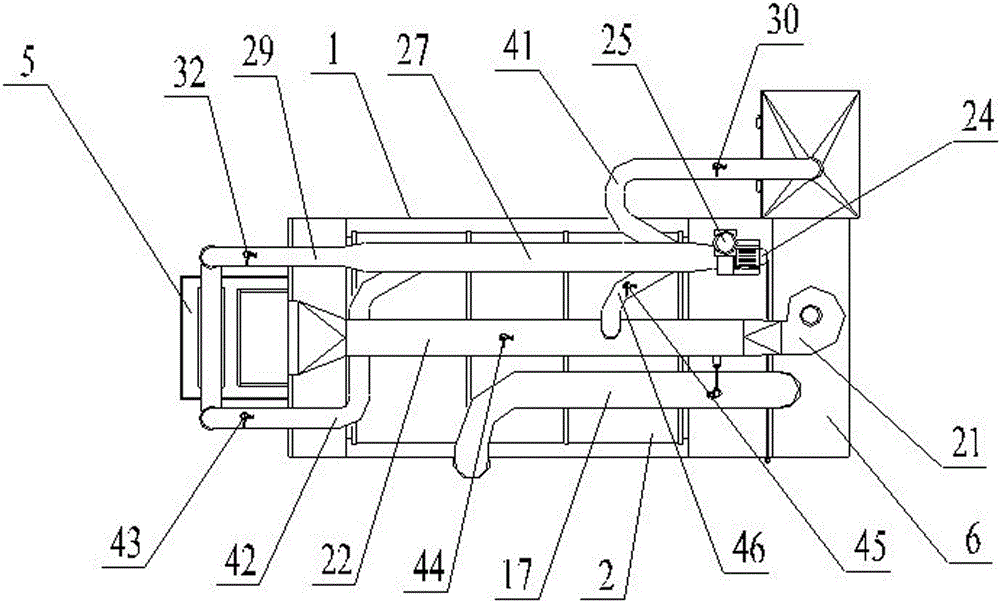

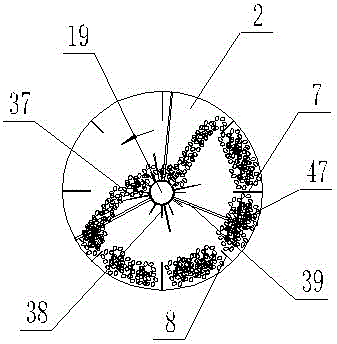

[0025] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

[0026] Such as figure 1 As shown, the present invention provides a dampening machine that can improve the uniformity of temperature increase and humidification of tobacco leaves and reduce crushing. The fixed frame 1 is provided with a drum 2, and the angle between the drum 2 and the horizontal direction on the fixed frame 1 is set at 3.5 degrees to 4.5 degrees, and the rotating speed of the drum 2 is adjusted between 8r / min and 16r / min. 2 is connected in rotation with the fixed frame 1, and the rotation connection between the drum 2 and the fixed frame 1 can be realized by setting idler transmission between the drum 2 and the fixed frame 1 in the actual production process. The front and rear ends of the drum 2 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com