Automatic paint spraying system for macromolecule leather

An automatic painting and polymer technology, applied in the direction of spraying devices, can solve problems such as poor stability and accuracy, and achieve the effects of improving consistency, improving painting efficiency and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

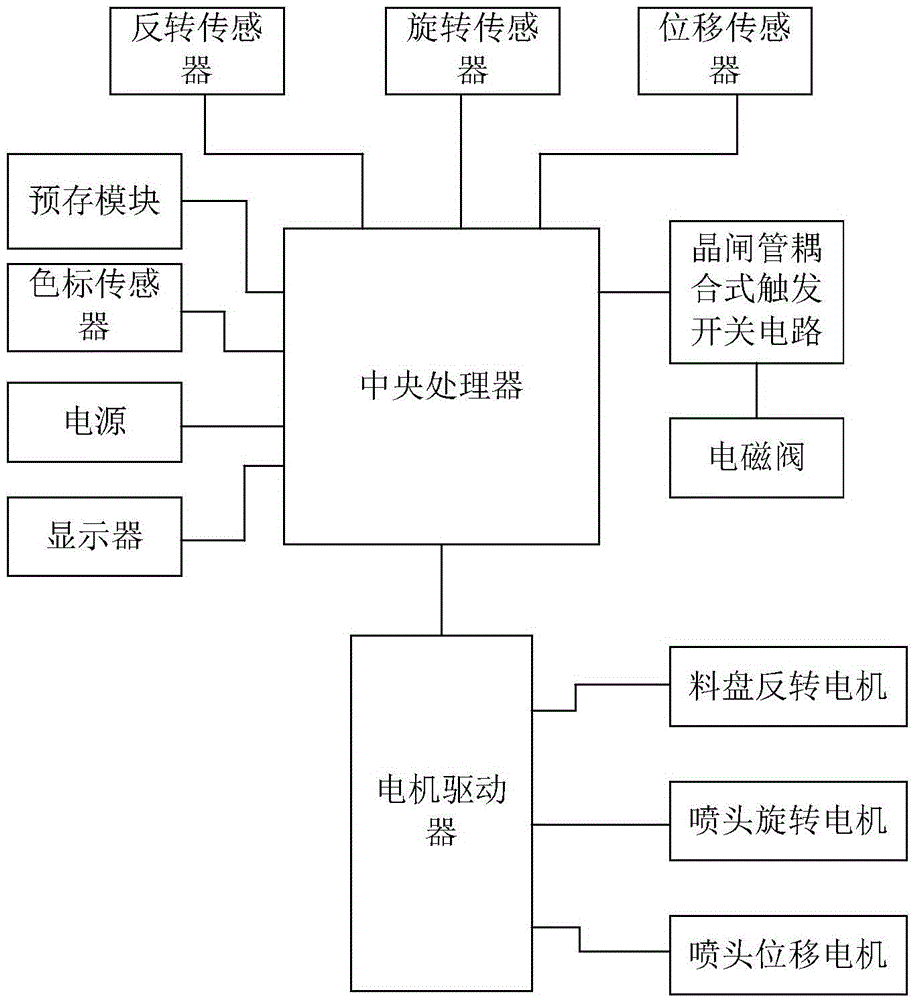

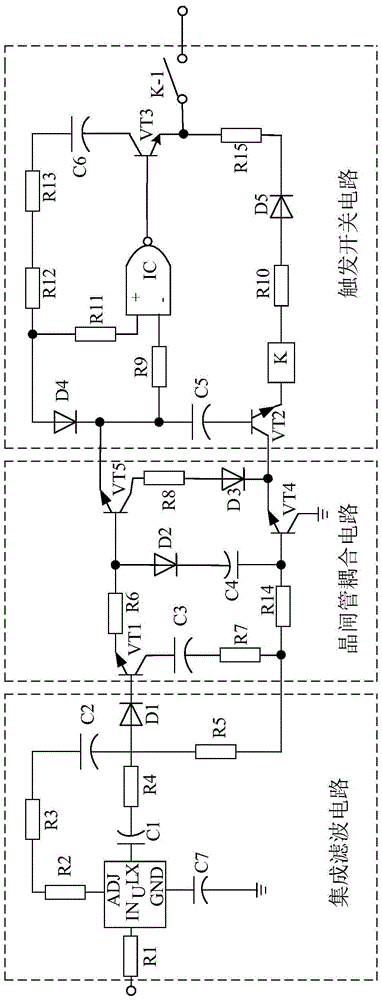

[0018] Such as figure 1 Shown, the present invention is mainly by central processing unit, the display that is all connected with central processing unit, power supply, pre-storage module, color mark sensor, reverse sensor, rotation sensor, displacement sensor, electromagnetic valve, motor driver, all with motor driver It is composed of a material tray reversal motor, a nozzle rotation motor, a nozzle displacement motor, and a thyristor-coupled trigger switch circuit whose input end is connected with the central processing unit and whose output end is connected with the solenoid valve. The power supply is 12V direct current, and the 12V direct current supplies power for the central processing unit.

[0019] For implementing the present invention better, described central processing unit is NCP1652 integrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com