Automatic polymer leather paint spraying system based on variable low-pass filter circuit

A low-pass filter circuit and automatic painting technology, which is applied in the direction of spraying devices, can solve the problems of poor stability and accuracy, and achieve the effects of improved consistency, strong controllability, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

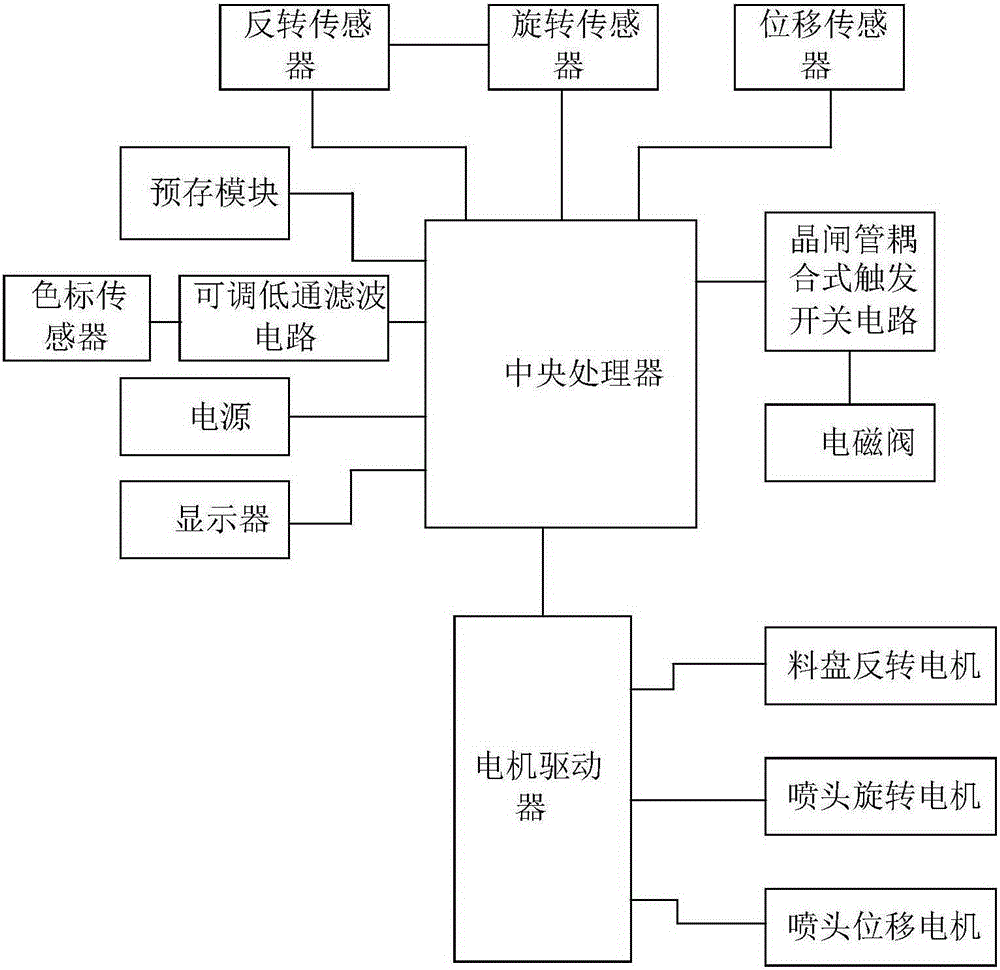

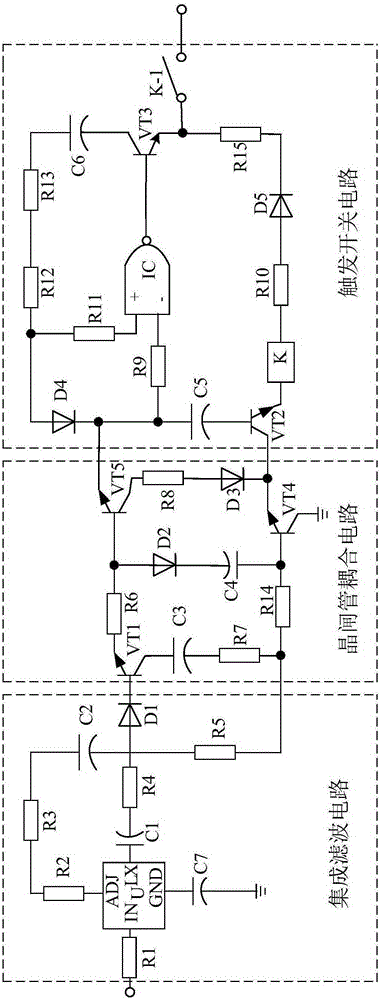

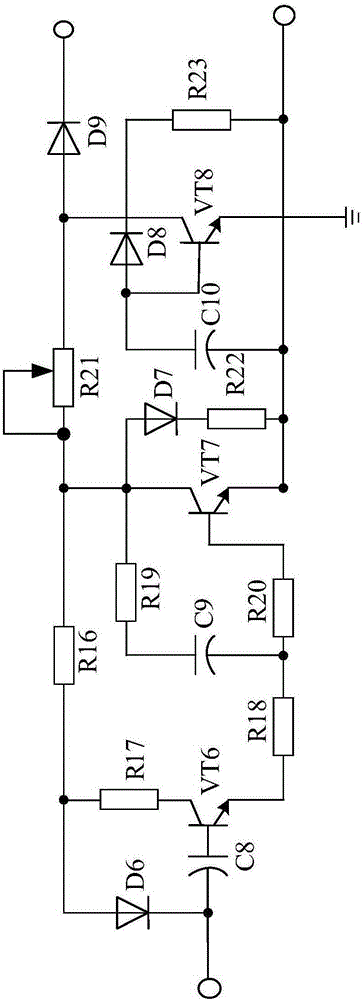

[0021] Such as figure 1 As shown, the present invention mainly consists of a central processing unit, a display, a power supply, a pre-stored module, a color mark sensor, a reverse sensor, a rotation sensor, a displacement sensor, a solenoid valve, a motor driver, and a material tray reversing motor connected to the motor driver. , nozzle rotation motor and nozzle displacement motor, a variable low-pass filter circuit whose input end is connected to the color mark sensor, whose output end is connected to the central processing unit, and whose input end is connected to the central processing unit, whose output end is connected to the solenoid valve It is composed of connected thyristor coupled trigger switch circuit.

[0022] For implementing the present invention better, described central processing unit i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com