Device using translation mechanism and crank rocker mechanisms to realize automatic egg receiving and carrying

A crank-rocker mechanism and crank-rocker technology, applied in the field of poultry and egg devices, can solve the problems of expensive equipment, increased production costs of poultry and egg manufacturers, high production costs, etc., and achieve the goals of reducing manpower, convenient maintenance, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

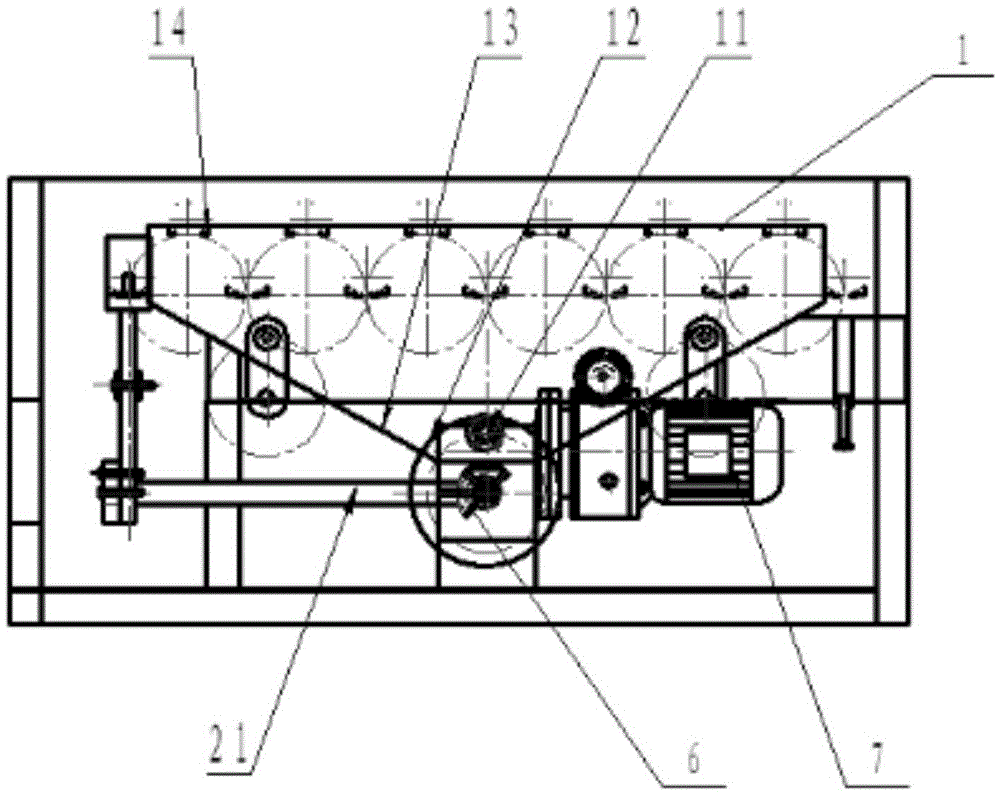

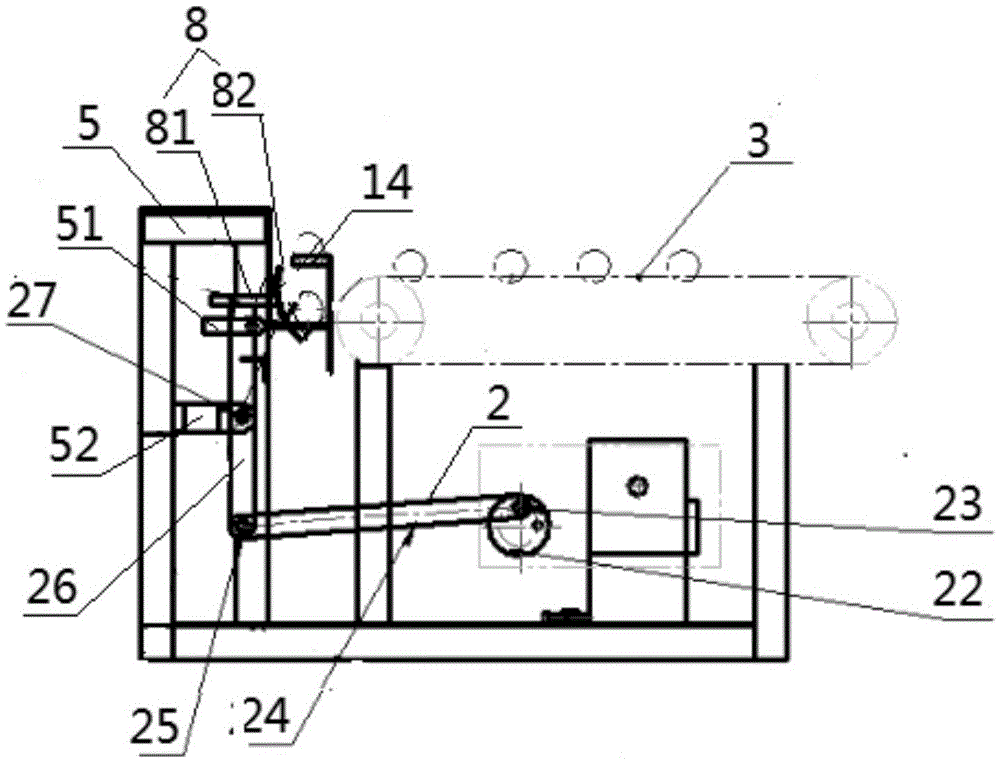

[0020] Such as figure 1 and figure 2 As shown, a device that uses two mechanisms of translational crank and rocker to realize automatic egg handling, including a frame 5, a base 4, a worm gear reducer 7, a translational transporting mechanism 1, a transmission device 3 and a crank and rocker mechanism 2 , the worm gear reducer 7 is fixed on the base 4 by screws; the translational transport mechanism 1 includes a pin shaft A11, a first eccentric wheel 12, a translational plate 13 and 6 egg holders 14, and the 6 holders The egg racks 14 are parallel to each other and installed on the top of the translation plate 13 in a straight line; the first eccentric wheel 12 is connected to the translation plate 13 through the pin shaft A11; the first eccentric wheel 12 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com