Cylinder cover with detecting and positioning steps and air passage detecting method

A technology for locating steps and cylinder heads, applied in the directions of cylinder heads, cylinders, measuring devices, etc., can solve problems such as air passage obstruction, loss of engine performance, etc., and achieve the effects of improving stability, saving costs and cycles, and facilitating discovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

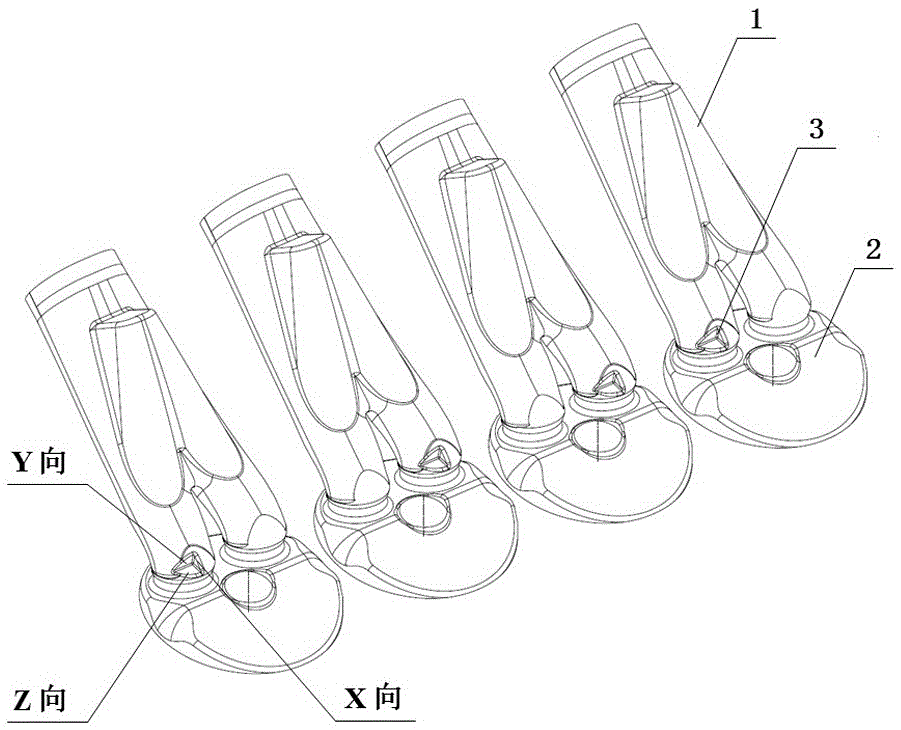

[0026] The cylinder head air passage with detection and positioning steps used in this embodiment is an integral structure, including air passage 1 and combustion chamber 2, and a triangular positioning step 3 is also provided at the throat of each air passage sand core (such as figure 1 ), the shortest side length of each surface of the triangular step 3 is not less than 5mm, the draft angle of each plane is less than 1°, and the casting fillet is less than or equal to 0.5mm.

Embodiment 2

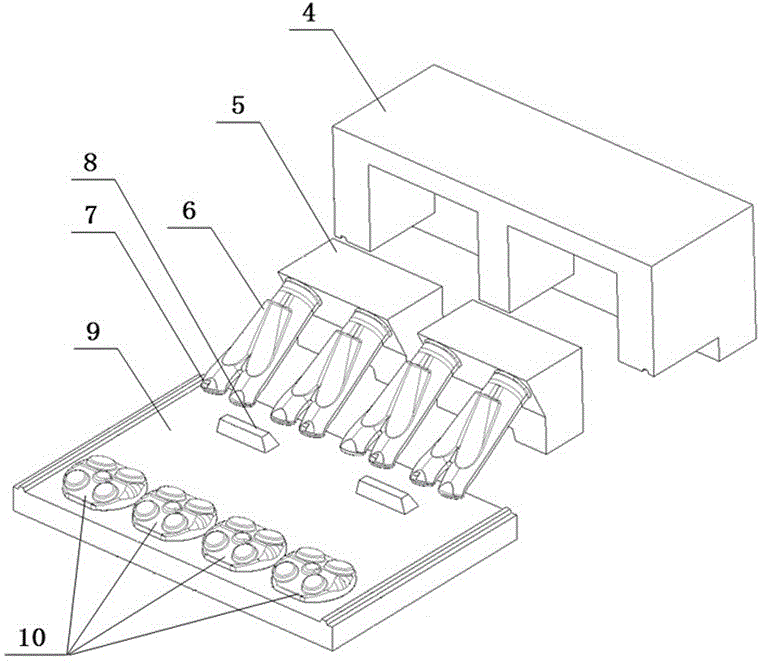

[0028] The cylinder head casting mold with detection and positioning steps adopted in this embodiment includes a side mold 4, an air passage sand core head 5, an air passage sand core 6, an air passage sand core positioning reference 8, a bottom mold 9 and a combustion chamber The insert 10 is also provided with a triangular positioning step 7 at the throat position of the airway sand core 6 (such as figure 2 ), the length of the shortest side of each face of the triangular positioning step 7 is not less than 5mm, the draft angle of each plane is less than 1°, and the edge fillet is less than or equal to 0.5mm.

Embodiment 3

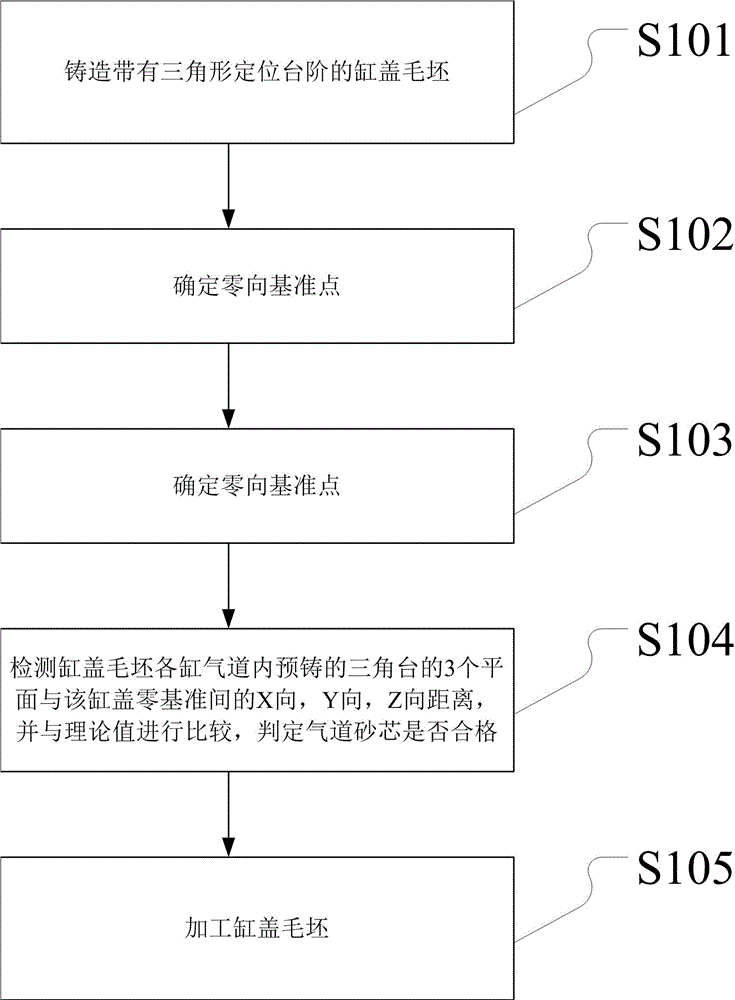

[0030] The cylinder head airway detection method adopted in this embodiment includes the following steps (such as image 3 ):

[0031] Step 101, casting a cylinder head blank with triangular positioning steps. Including: firstly make a sand core mold, and set a triangular step at the throat of each air channel sand core at a distance of 4 to 5 mm from the interface between the air channel and the combustion chamber. The plane draft angle slope is less than 1°, and the edge fillet is less than or equal to 0.5mm;

[0032] Secondly, using the above-mentioned sand core mold, the airway sand core is manufactured through the production process of sand washing and crusting, and the core body after mold opening is guaranteed to be complete under the premise of not using sand core filling agent;

[0033] Finally, on the basis of the above-mentioned airway sand core, the outer mold of the cylinder head is clamped and cast to produce a cylinder head blank with an airway cavity.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com