Device for clamping and releasing workpiece

A workpiece clamp and workpiece technology, applied in the field of workpiece clamping and loosening devices, can solve problems such as poor stamping accuracy, large workload, and difficulty in controlling accuracy, and achieve precise positioning, improved machining accuracy, great practical value and creativity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

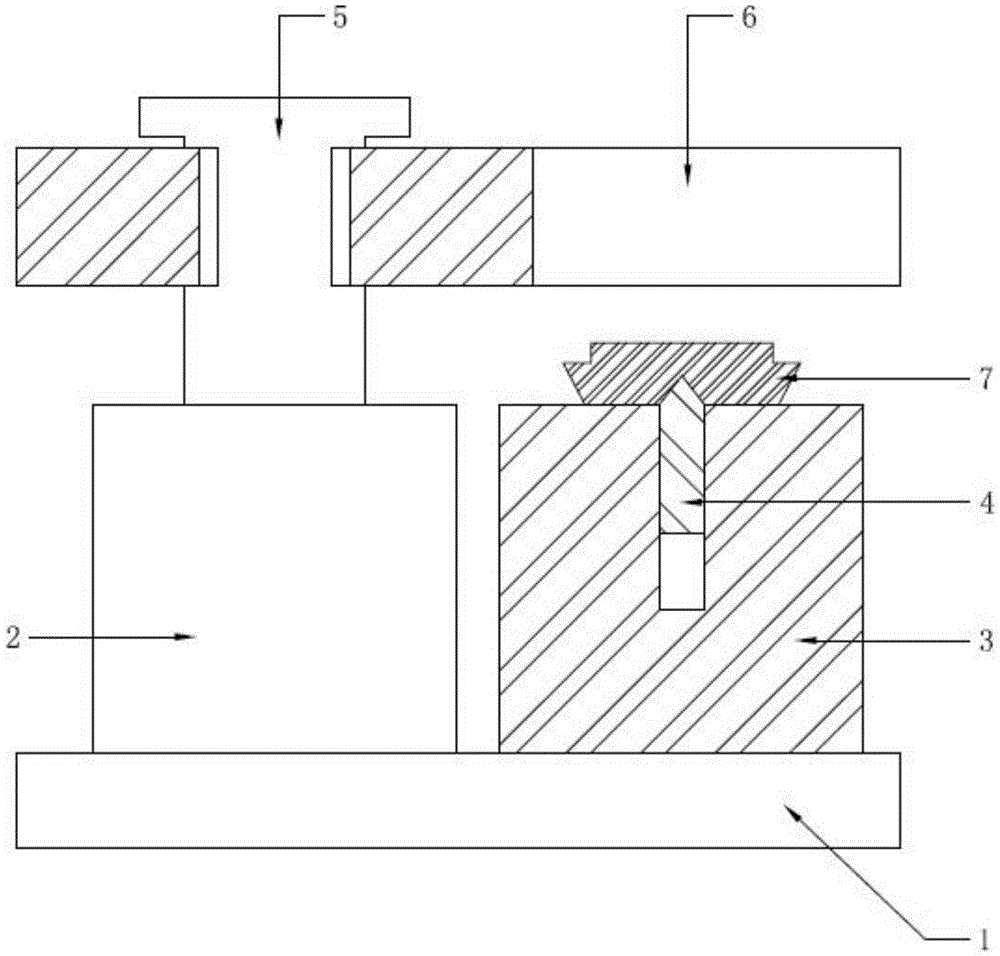

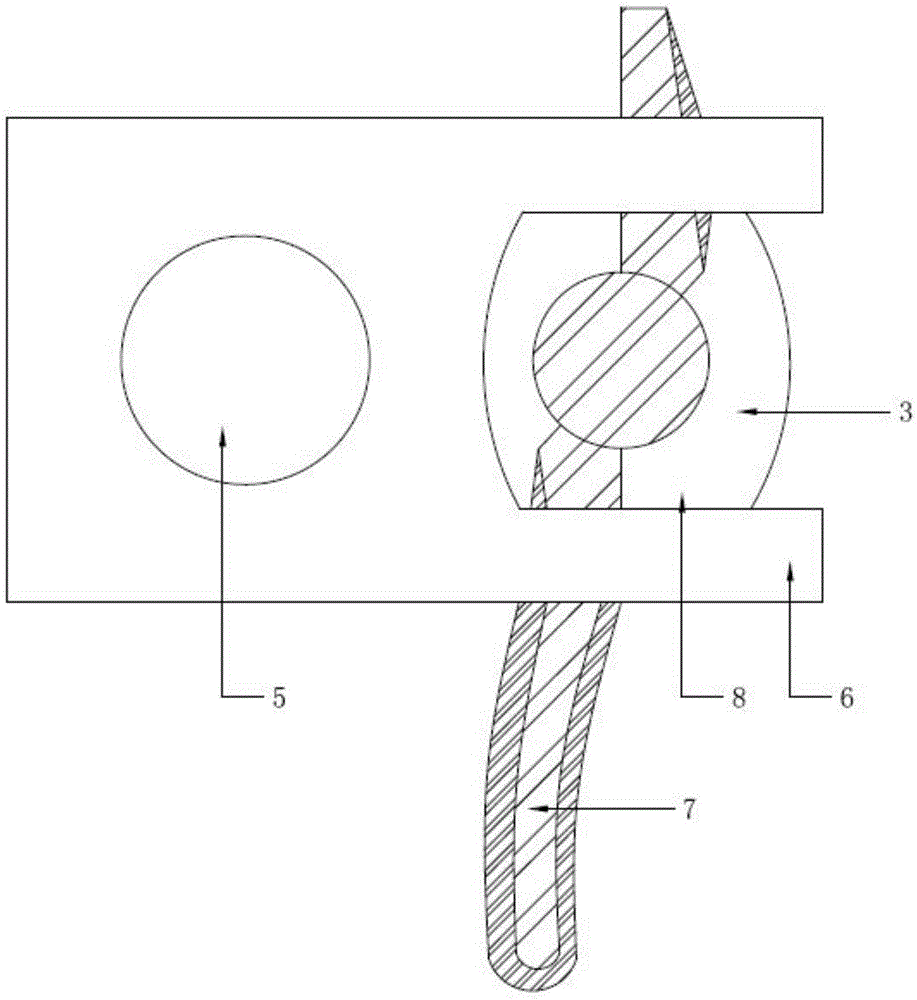

[0023] A device for clamping and loosening workpieces, comprising a base 1, the base 1 is provided with a driving mechanism 2 and a positioning seat 3, the top of the driving mechanism 2 is connected to a pressing block 6 through a transmission mechanism 5, and the pressing block 6 One end extends to the top of the entire positioning seat 3, and an open working window 8 is provided in the middle of the end of the pressure block 6 to face the center position of the positioning seat 3, and the center position of the upper end surface of the positioning seat 3 is provided with a downwardly fixed positioning pin 4. The positioning pin 4 can move in the vertical direction inside the positioning seat 3, and the positioning pin 4 is installed and fixed to the workpiece 7 to be worked.

[0024] The driving mechanism 2 is arranged on one side of the base 1 , and the positioning seat 3 is arranged on the other side of the base 1 . The flexible connection between the bottom end of the po...

Embodiment 2

[0027] The difference from Embodiment 1 is that there are two driving mechanisms 2, which are respectively arranged on both sides of the base 1. The seat 3 is located in the middle of the base 1 .

Embodiment 3

[0029] The difference from Embodiment 1 is that no movable mechanism is provided at the bottom of the positioning pin 4, and the body of the positioning pin 4 is a sliding device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com