Patents

Literature

72results about How to "Realize one clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

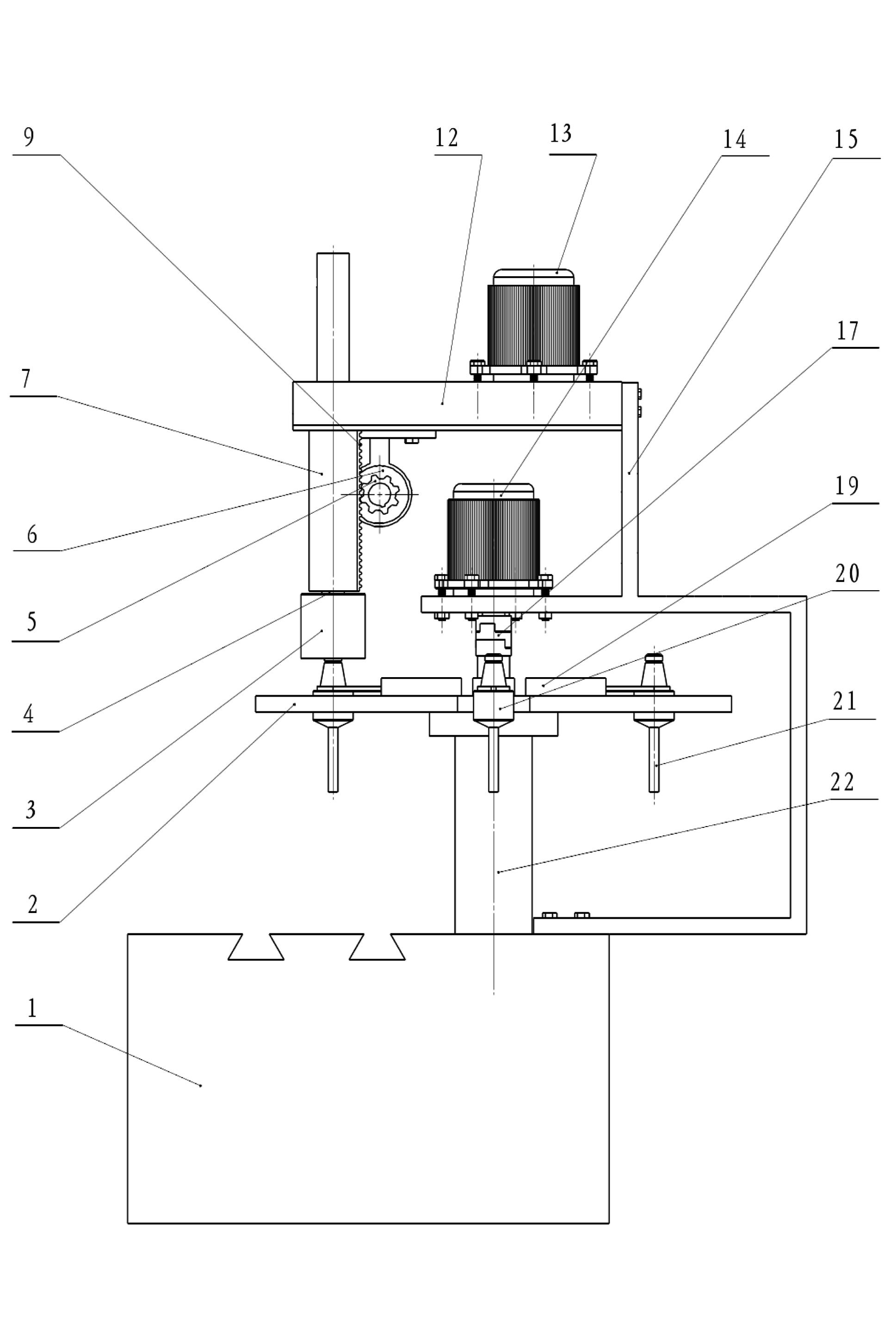

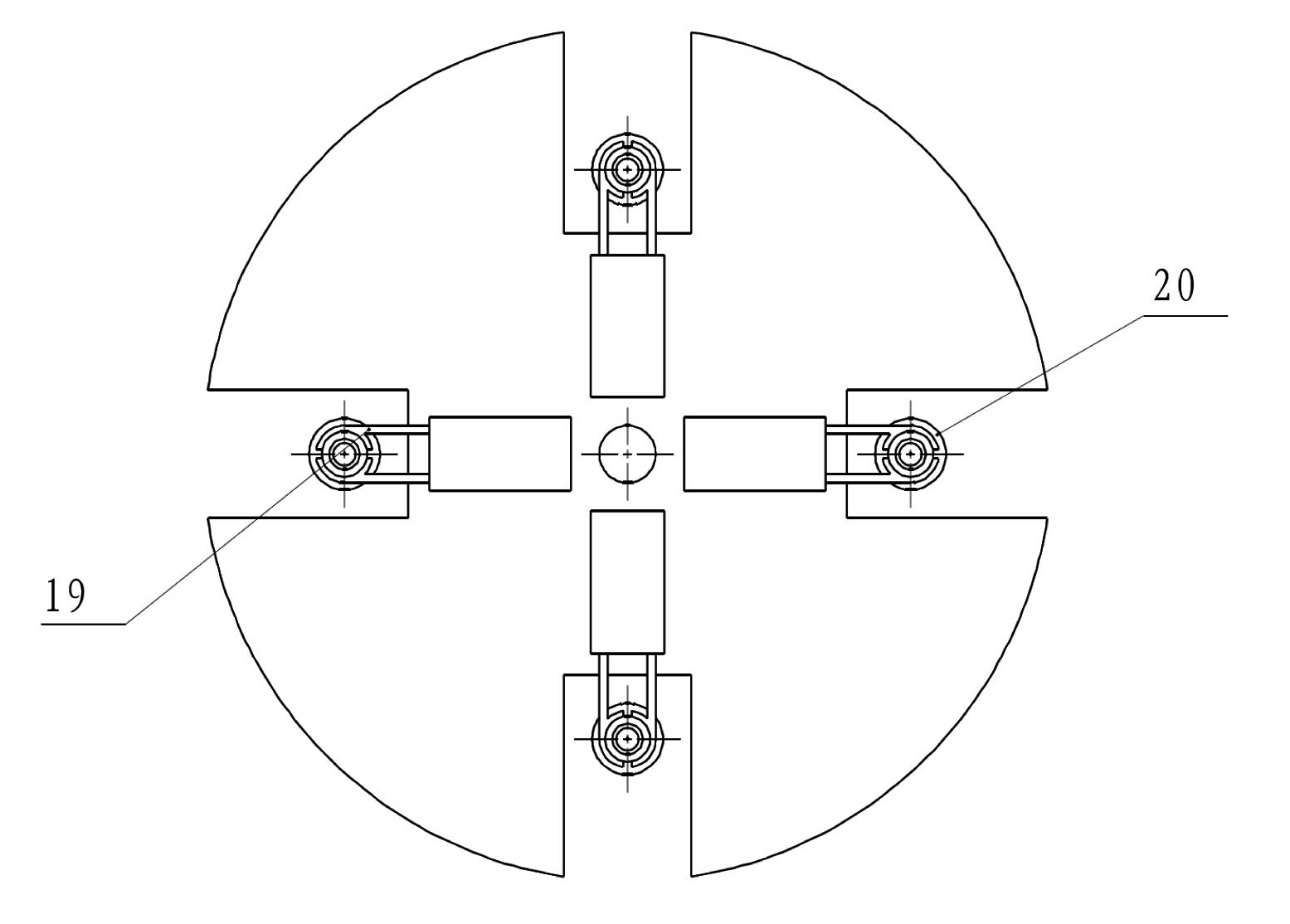

Multi-head numerical control drilling machine

InactiveCN101982269AClear and concise structureEasy to maintainPositioning apparatusBoring/drilling componentsNumerical control systemDrill bit

The invention discloses a multi-head numerical control drilling machine, which comprises a base, a tool changing mechanism, a drill bit mechanism and a feeding mechanism, wherein the base is provided with a workbench, an upright post is fixedly arranged on the base, and the top of the upright post is provided with the tool changing mechanism; a supporting frame is fixedly arranged on the base; the drill bit mechanism is arranged on the supporting frame, the drill bit mechanism is connected with the feeding mechanism, and the feeding mechanism drives a main shaft sleeve of the drill bit mechanism to move along the vertical direction so that a pneumatic clamp arranged on the main shaft sleeve can move along the vertical direction; and the control ends of the tool changing mechanism, the drill bit mechanism and the feeding mechanism are connected with the signal output end of a numerical control system. The tool changing mechanism, the drill bit mechanism and the feeding mechanism are mutually independent, so the drilling machine has clear and compact structure and is easy to maintain; and the mechanisms are controlled uniformly by the numerical control system so as to increase the operation flexibility, improve the production efficiency and reduce the cost. The drilling machine can be widely applied in the machining field.

Owner:林颖

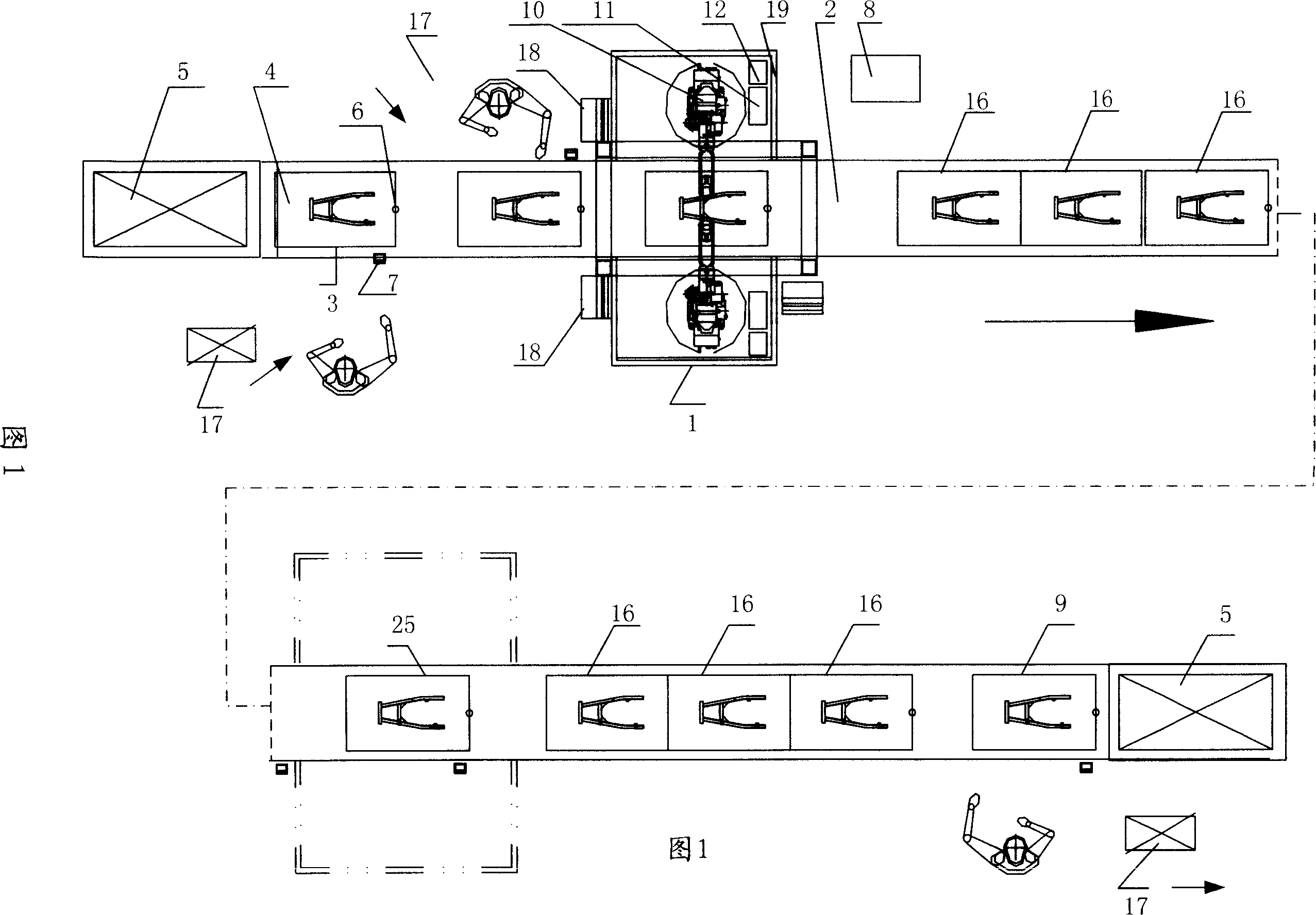

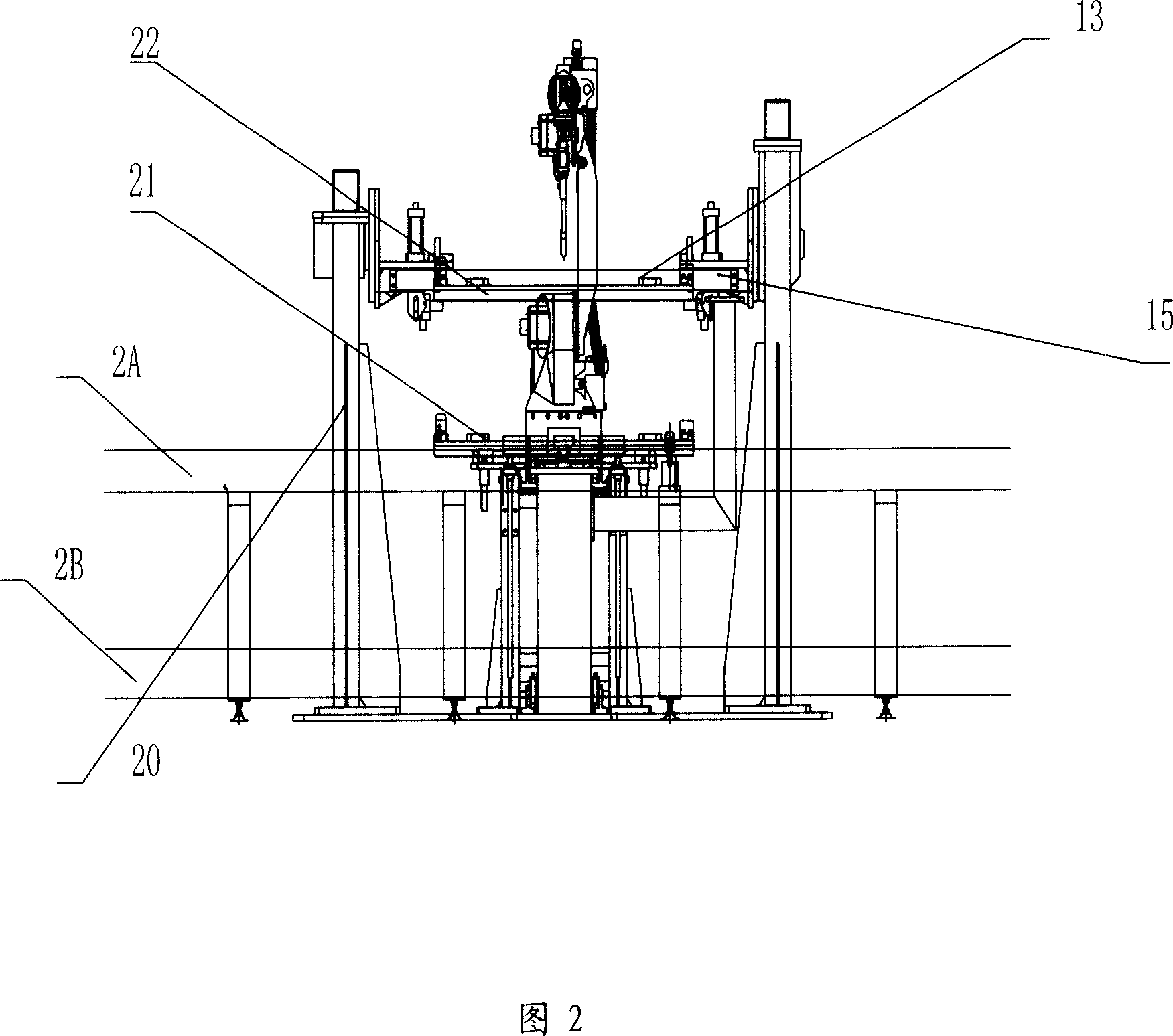

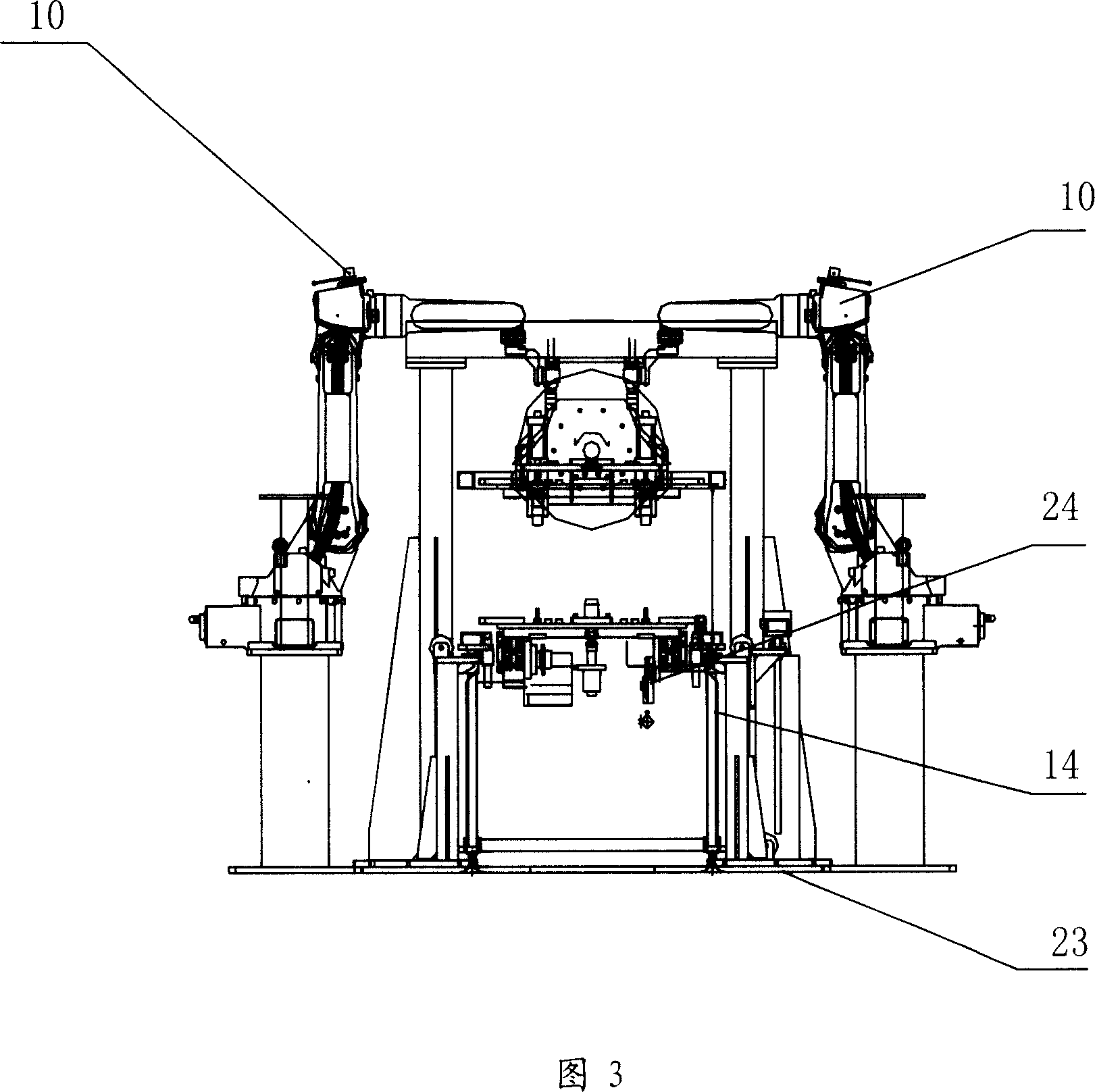

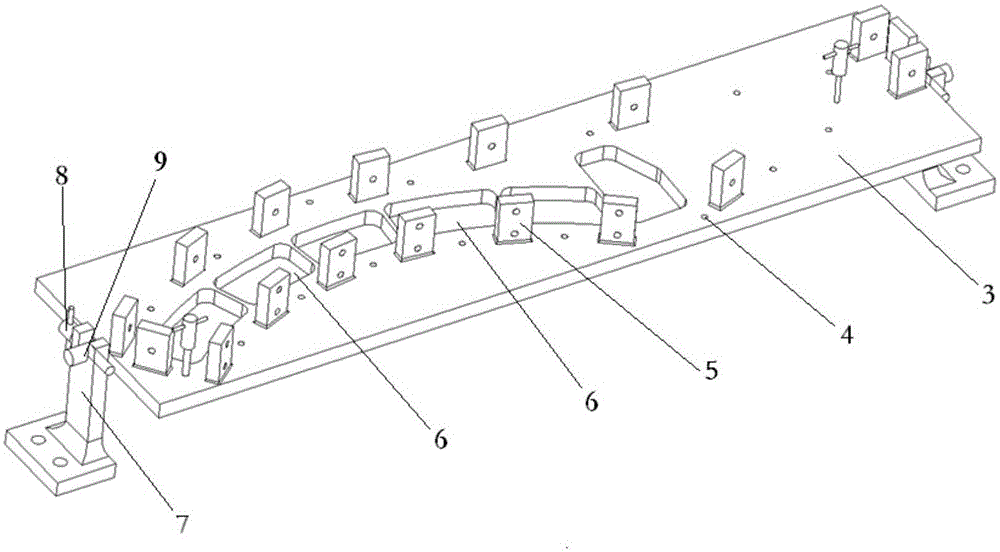

Welding production line with matched clamp

InactiveCN1939651AEffective combinationReduce targeting requirementsWelding/cutting auxillary devicesAuxillary welding devicesProduction lineWelding power supply

A welding production line with following fixture is composed of a conveying line, a master control cabinet, two lift units at both ends of said conveying line, several workstations arranged along said conveying line, a following welding fixture, robot welding station consisting of welding robot, control cabinet and power supply, a displacing machine, a lift unit for lifting said following welding fixture from conveying line to said displacing machine, and a fast clamping unit on said displacing machine.

Owner:CHONGQING ZONGSHEN INNOVATION TECH RES INST CO LTD

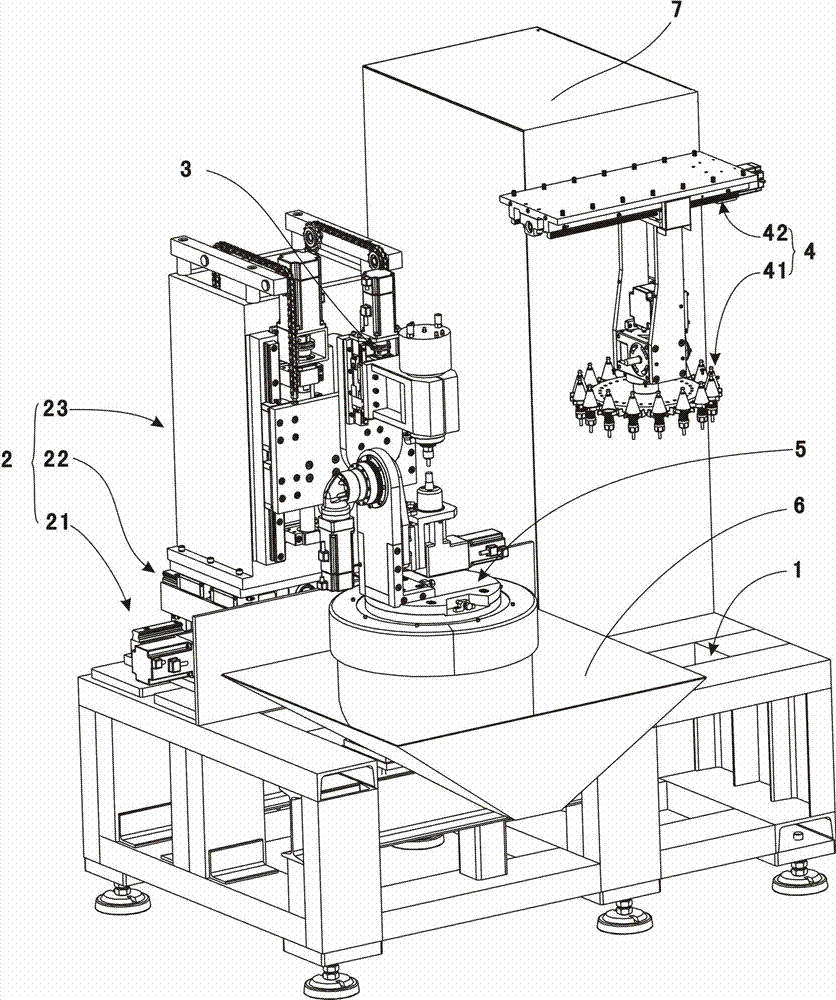

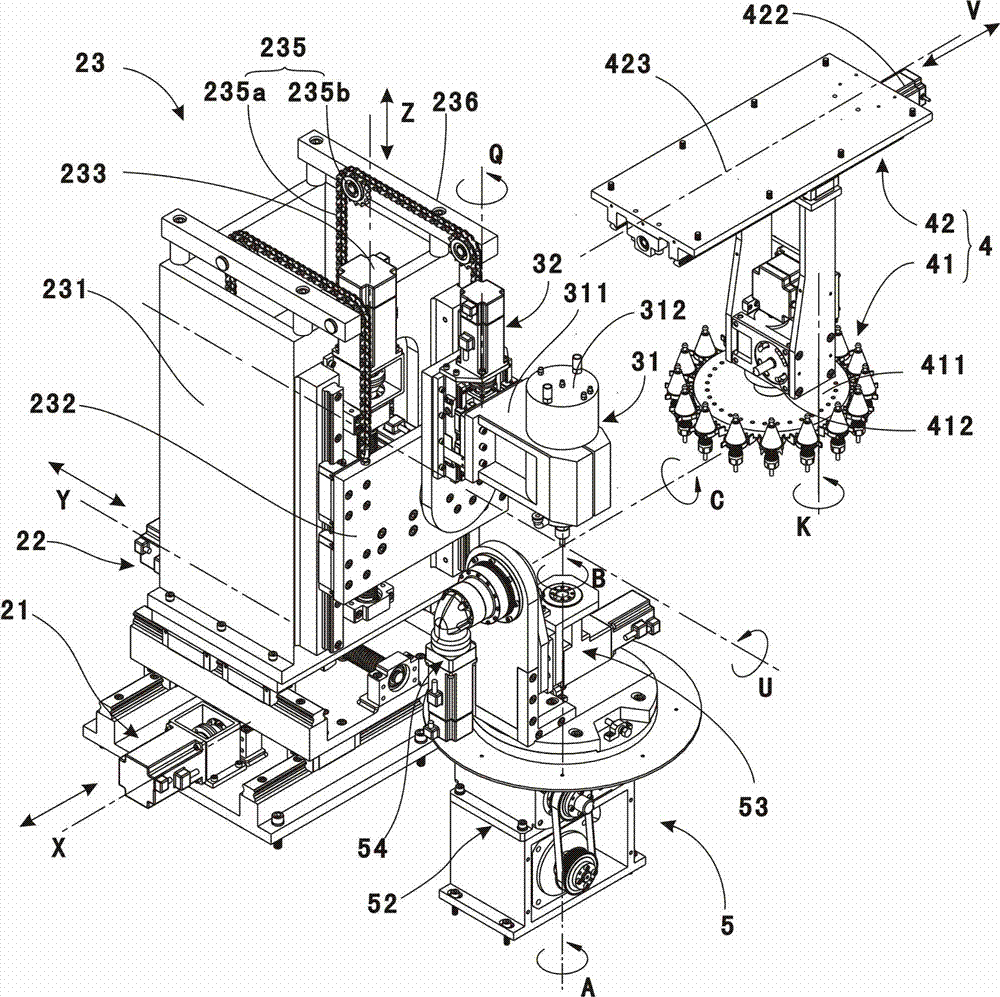

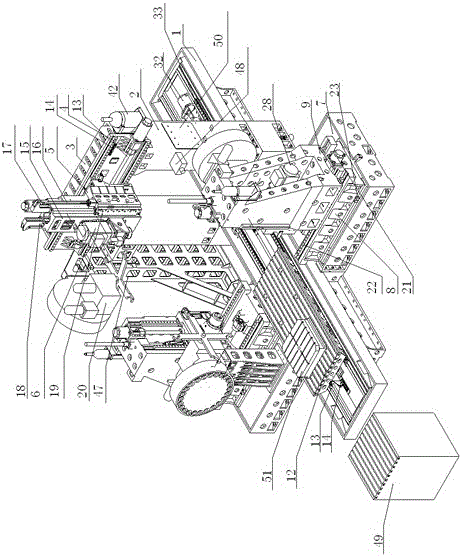

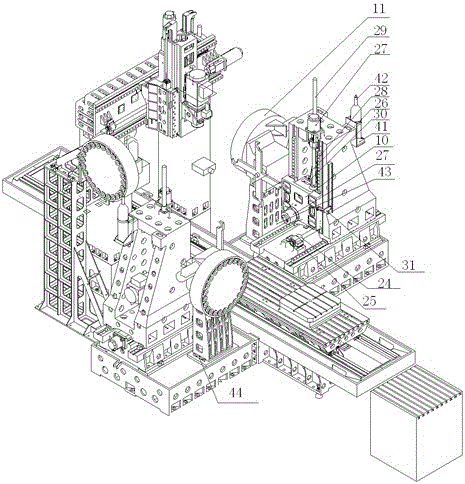

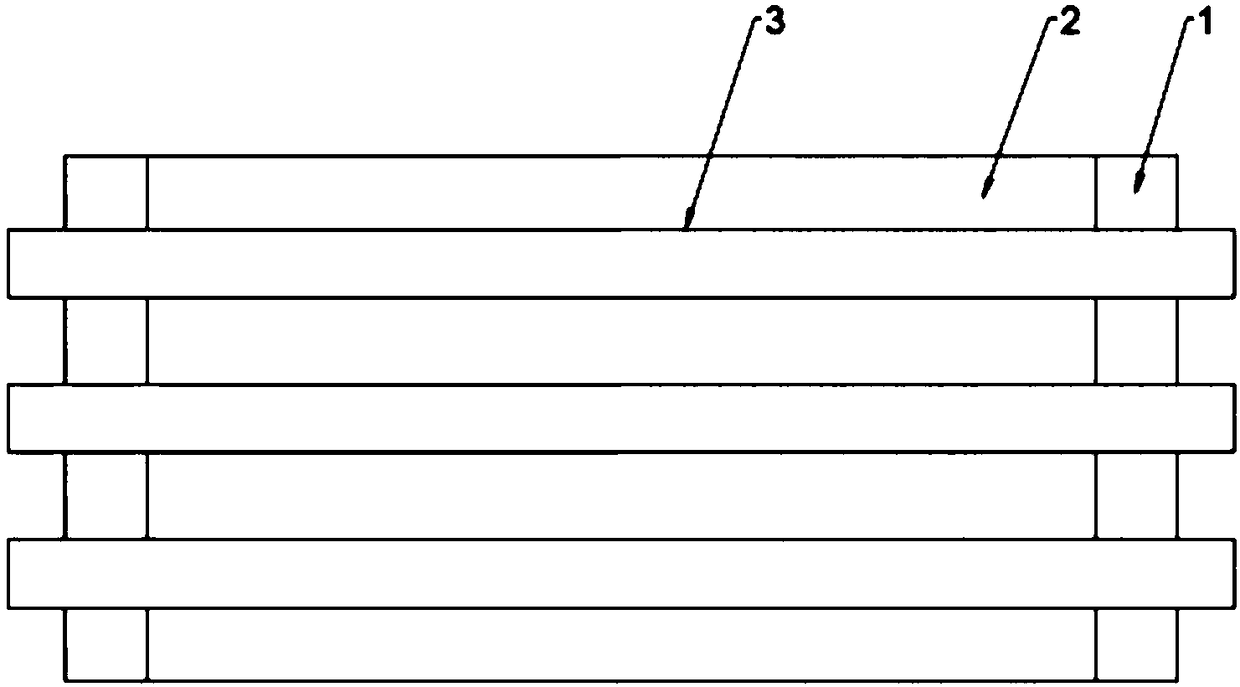

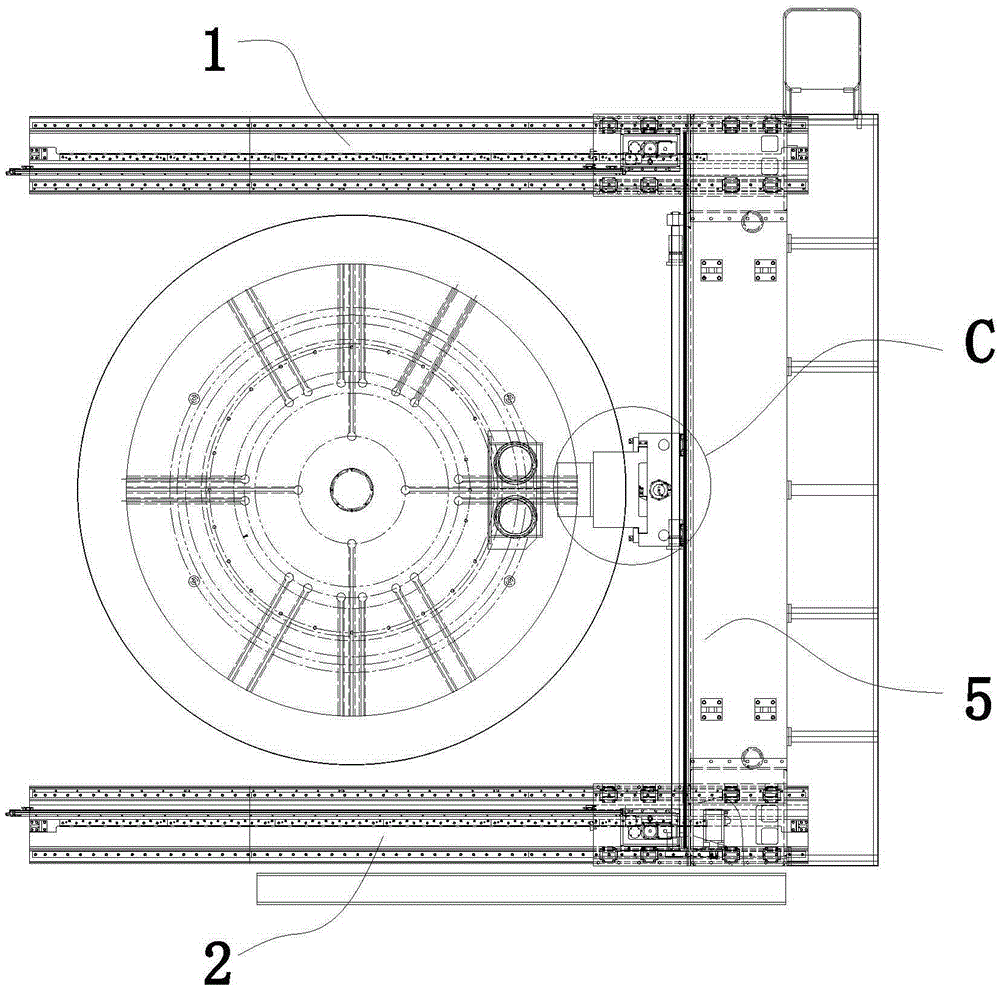

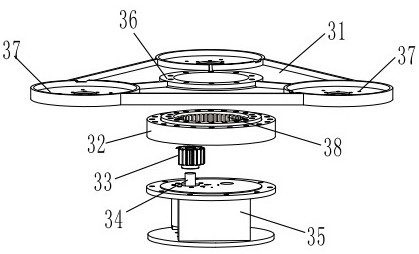

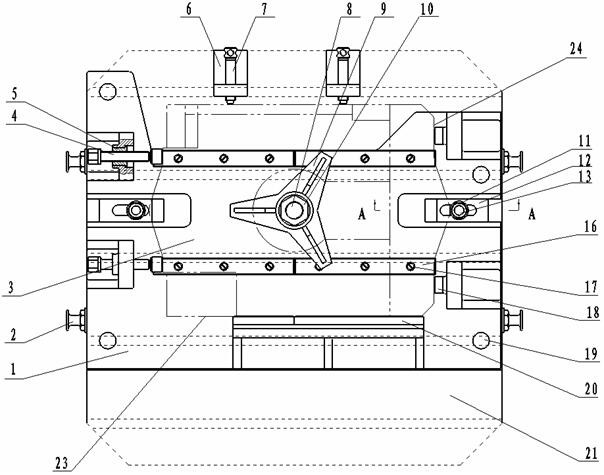

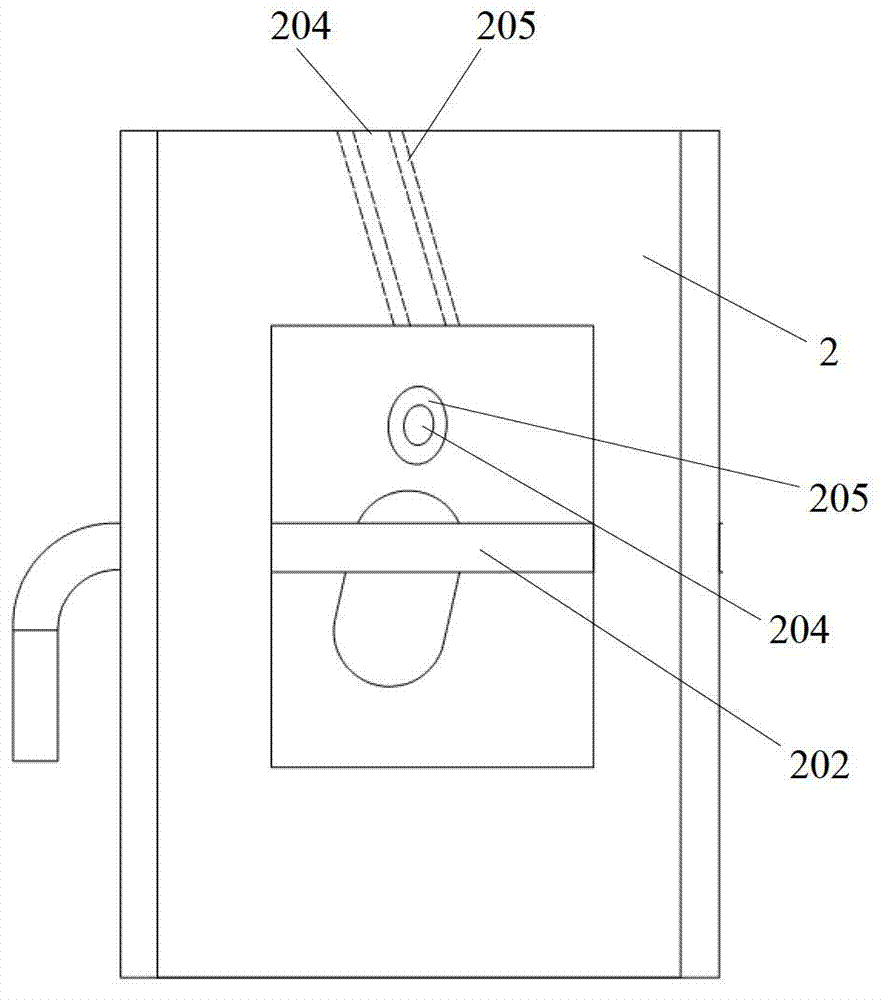

Numerical control machining tool and rotary work platform thereof

InactiveCN103084854ARealize one clampingGuaranteed positioning accuracyLarge fixed membersPositioning apparatusNumerical controlEngineering

The invention discloses a numerical control machining tool and a rotary work platform thereof. The Numerical control machining tool comprises a chassis, a main shaft device, a translation device and the rotary work platform, wherein the main shaft device is connected with the chassis through the translation device, the translation device is used for driving the main shaft device to translate along an axis X, an axis Y and an axis Z, the axis X, the axis Y and the axis Z are perpendicular to each other, and the rotary work platform is fixed on the chassis. The rotary work platform comprises a clamp component used for clamping workpieces, an axis A component, an axis B component and an axis C component, wherein the rotary work platform is capable of driving the workpieces to rotate around an axis A , an axis B and an axis C. Positional angles of cutters and the workpieces can be adjusted at any time, so that the numerical control machining tool is enabled to be provided with flexibility and softness, a best cutting point can be fully used for carrying out cutting. High-efficiency high-quality machining of products which are provided with diversity, the flexibility and complex shape is guaranteed, meanwhile, clamping the workpieces at one time is achieved, that is the numerical control machining tool is capable of finishing combined machining of the products accurately.

Owner:深圳市玮之度科技发展有限公司

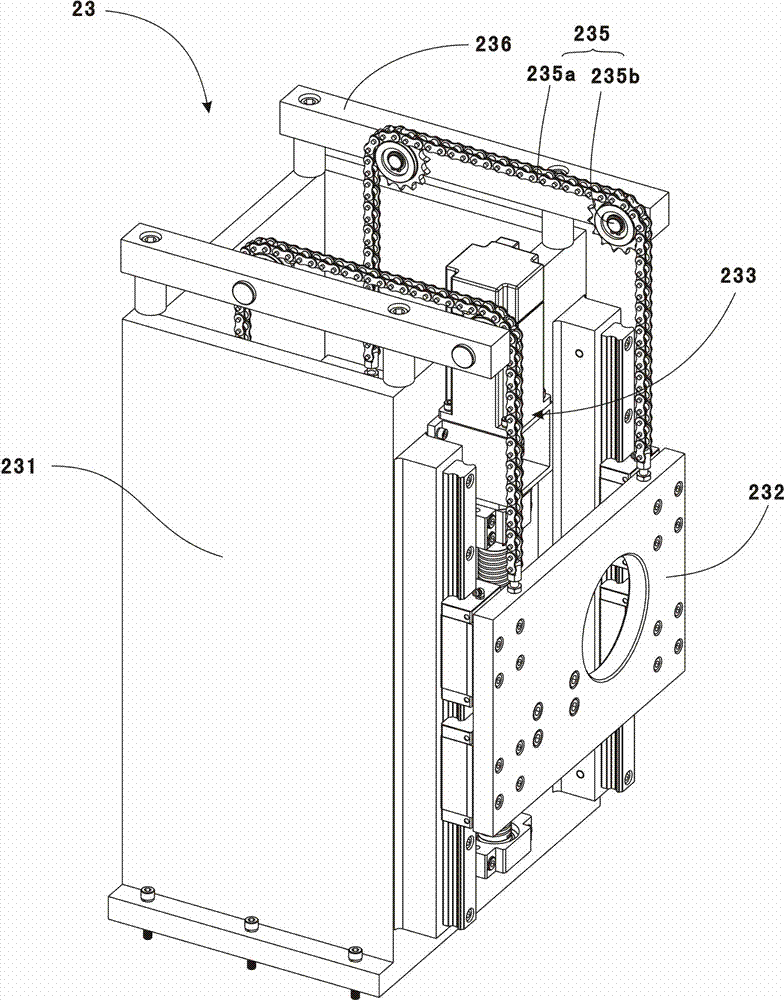

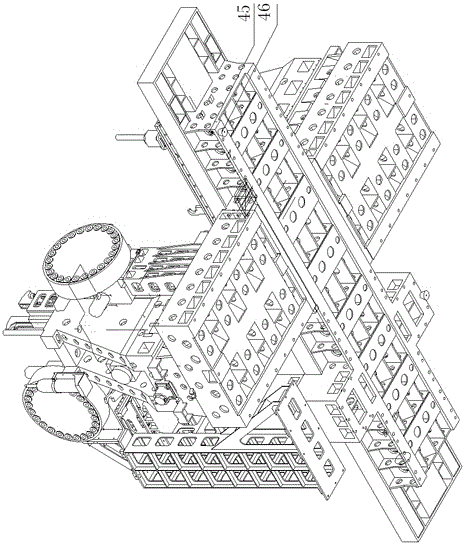

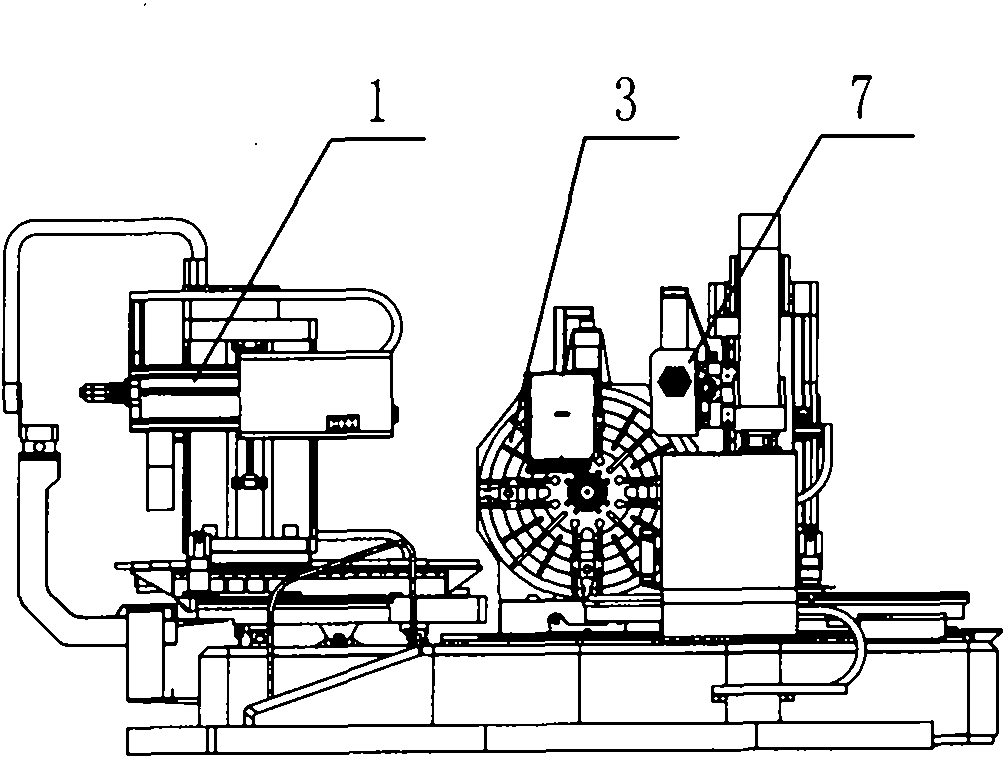

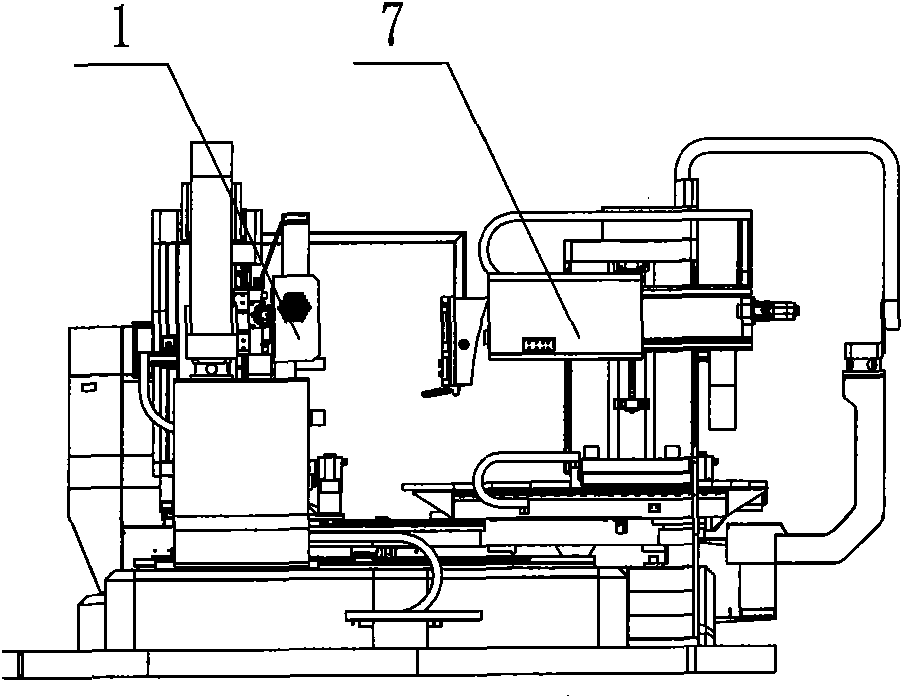

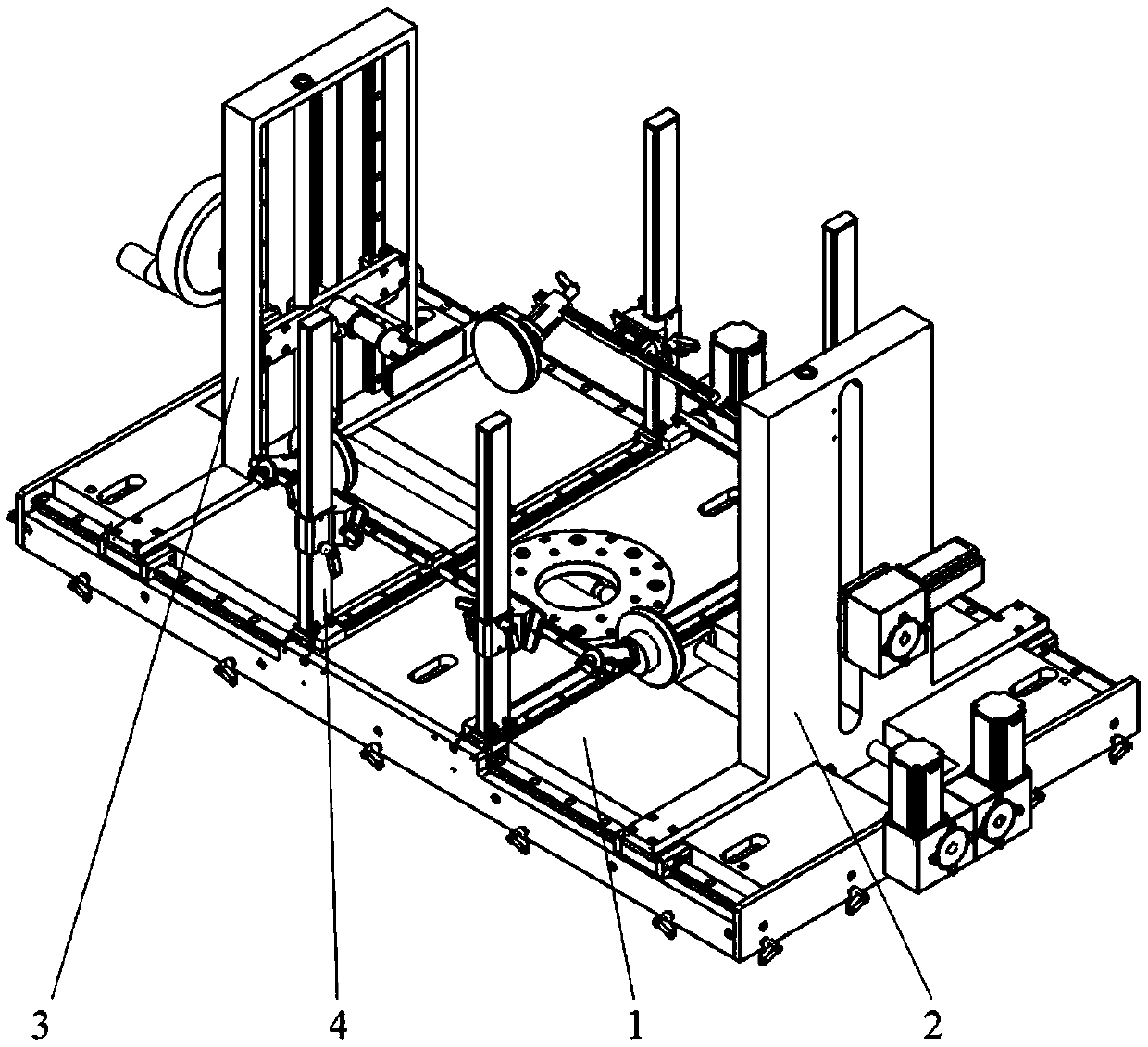

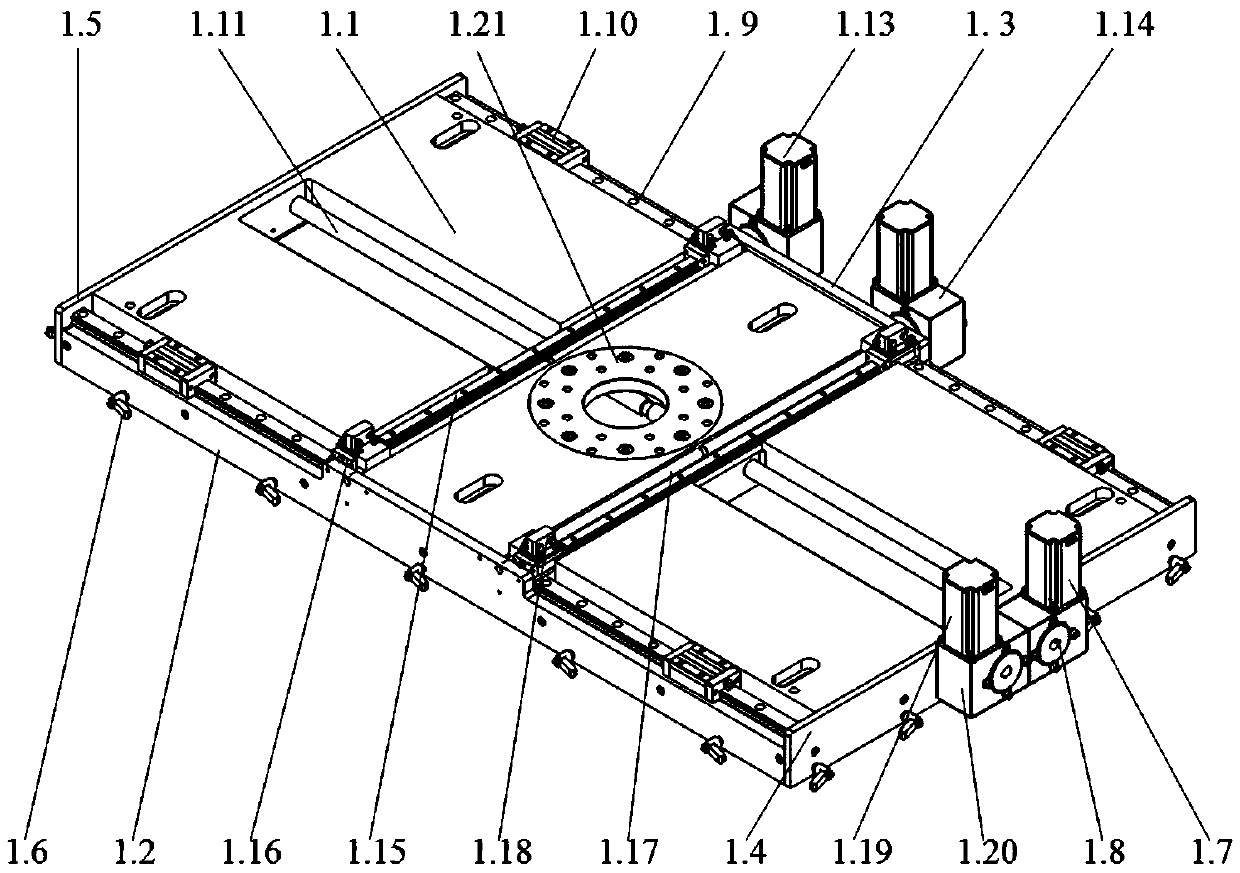

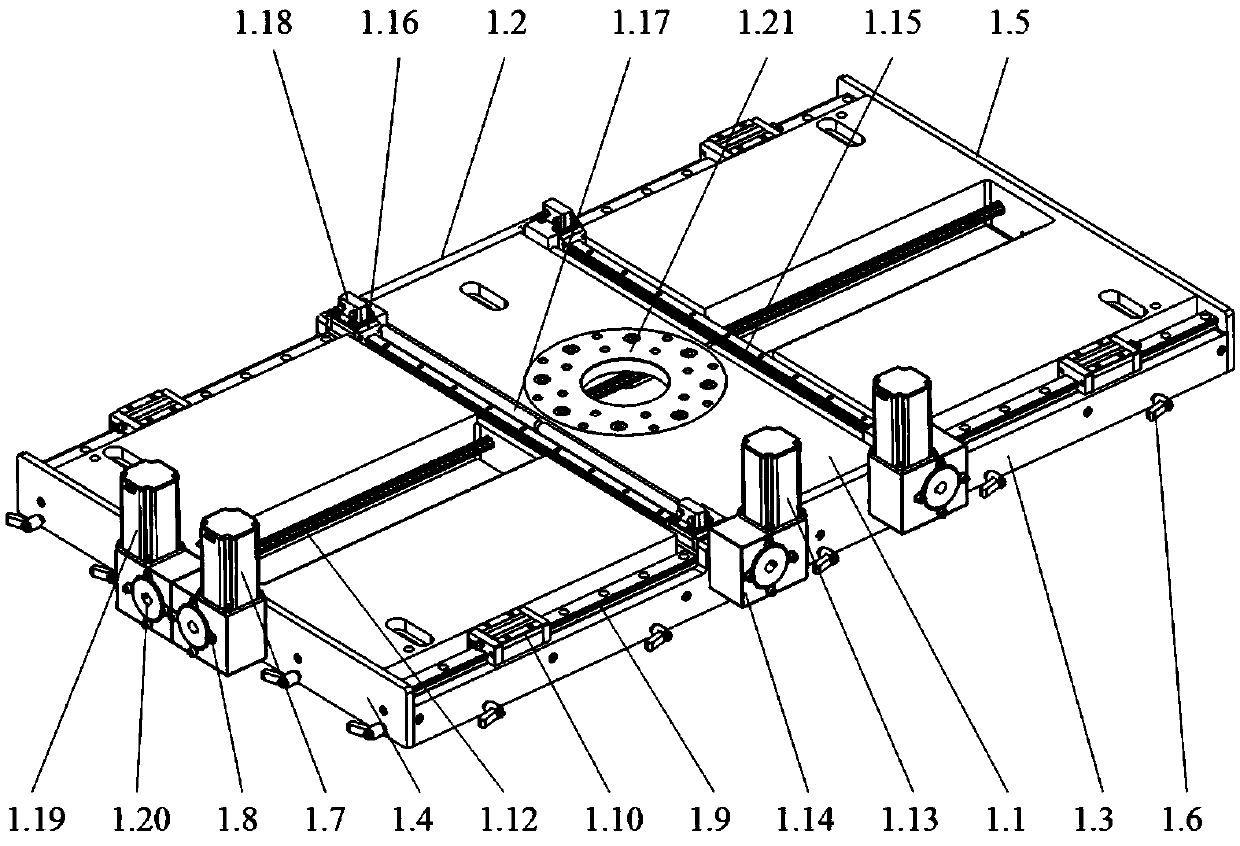

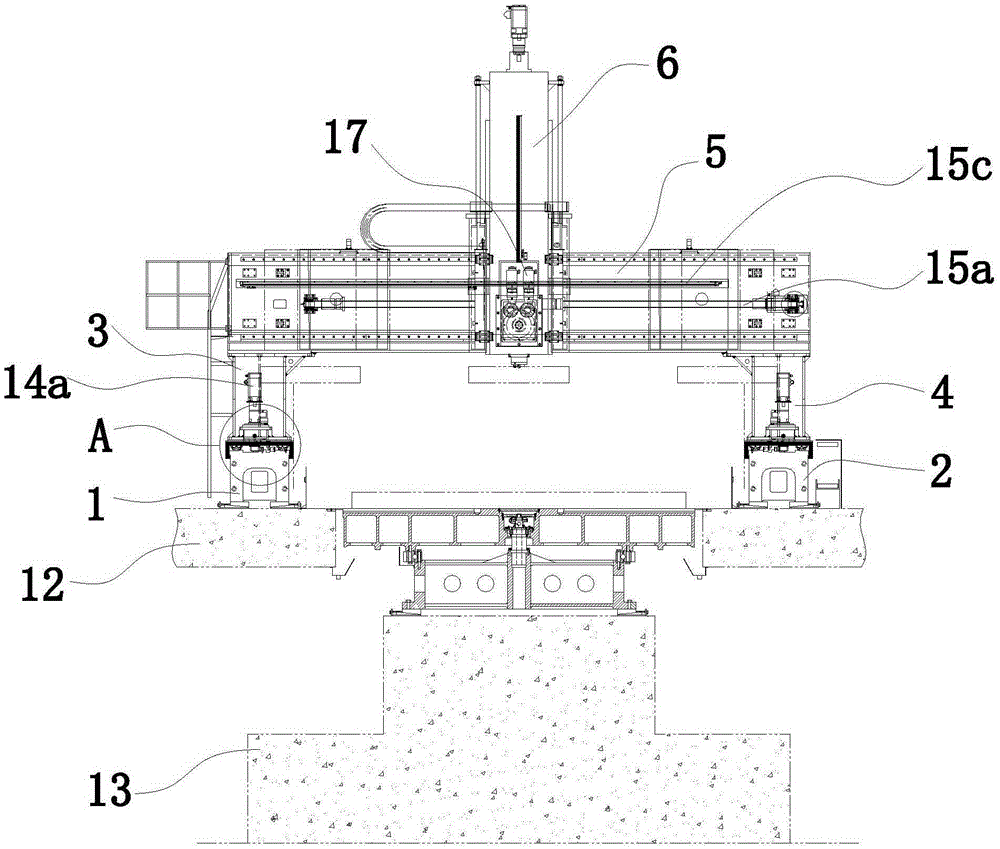

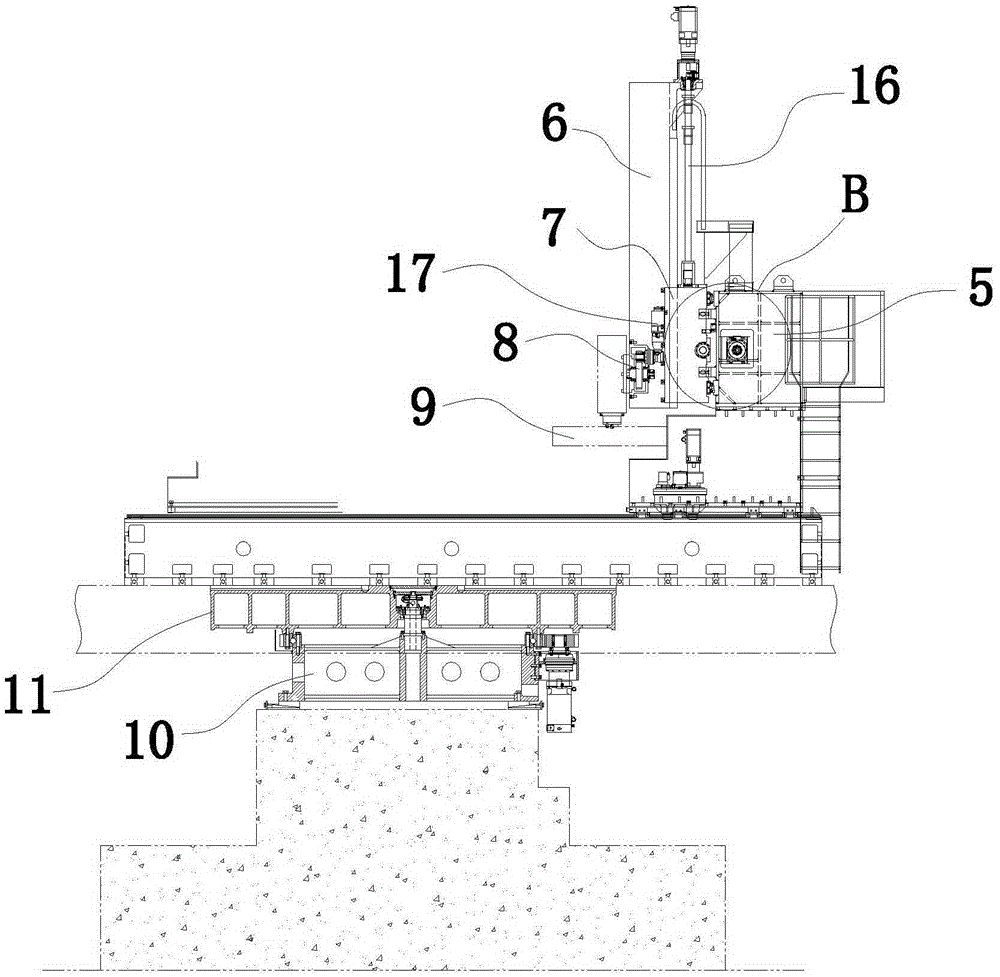

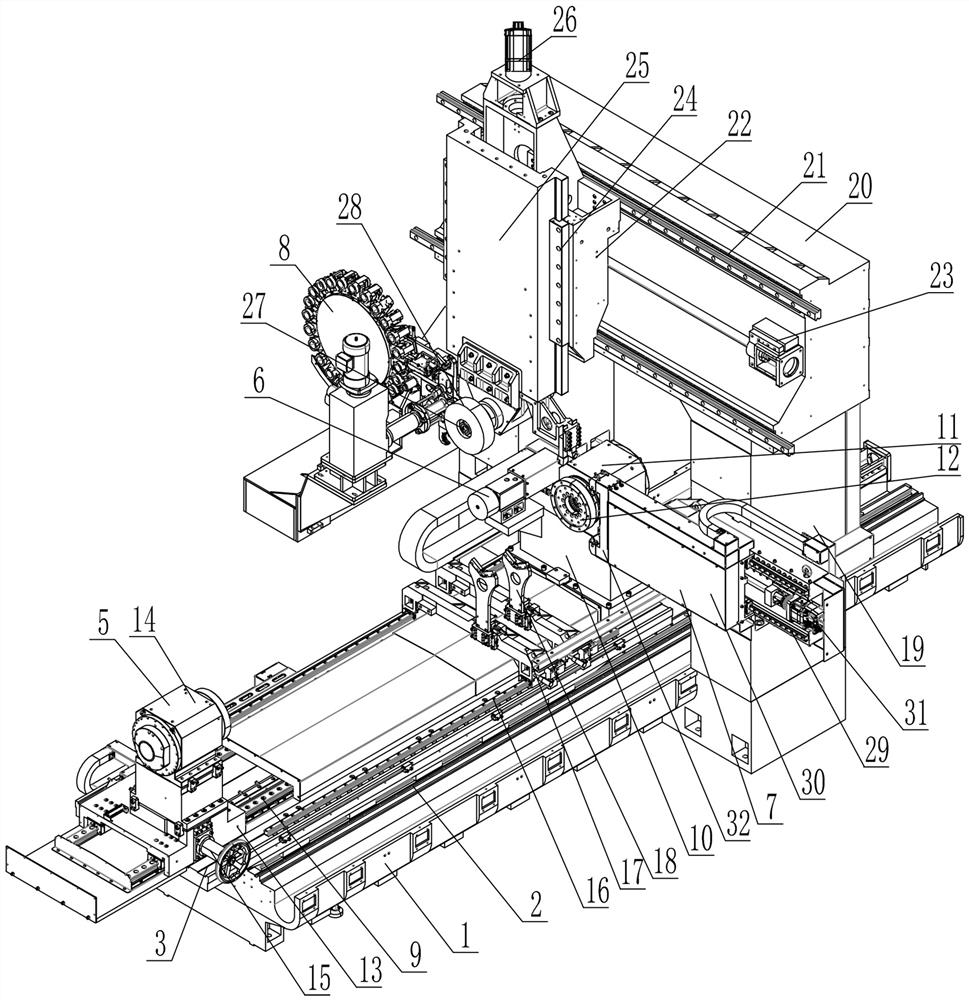

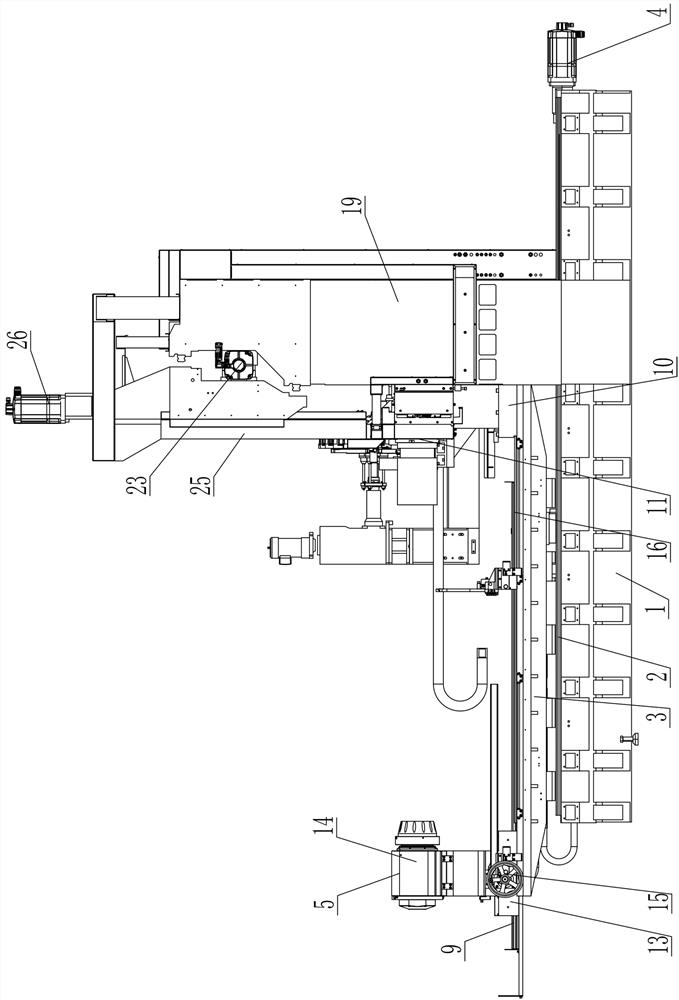

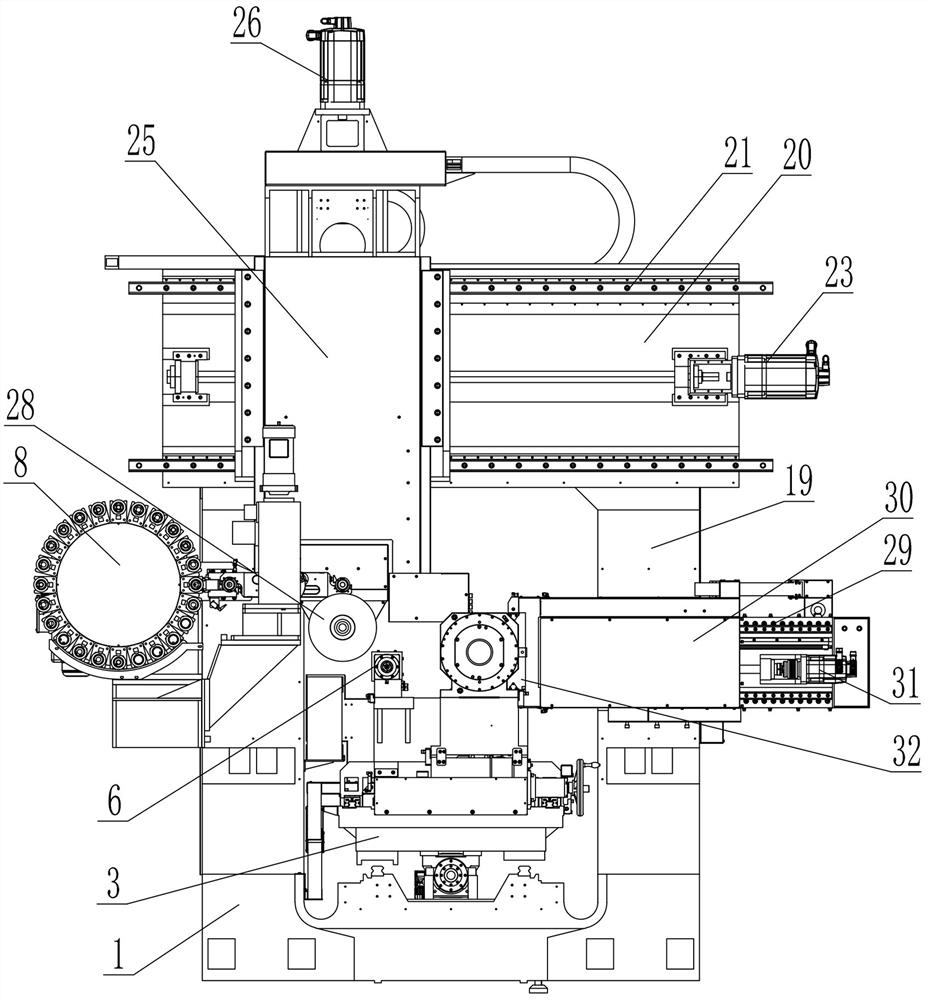

Composite flexible manufacturing unit

ActiveCN106625030ACompact structureSmall footprintFeeding apparatusLarge fixed membersNumerical controlCommon base

The invention relates to numerically-controlled machine tools, in particular to a composite flexible manufacturing unit, and mainly aims to solve the technical problems that an existing flexible manufacturing unit is large in floor space and high in investment, large and medium key part machining is large in error due to multiple clamping and multiple positioning, low in machining precision and small in application range, and the like in the prior art. The composite flexible manufacturing unit comprises a flexible manufacturing unit base and is characterized in that at least one gantry machining center, at least one horizontal machining center, at least one vertical machining center base, at least one machine tool body, at least one saddle, at least one standing column and at least one spindle box are connected to the flexible manufacturing unit base. The flexible manufacturing unit is provided with a common base and a common working table which formed by the machining centers, a common flexible clamp and a common central control device, a conveying device is arranged outside the flexible manufacturing unit, the base is connected with the gantry machining centers and the horizontal machining centers composited to the same machine tool, and all of or part of the vertical machining centers are provided with tool magazines.

Owner:HANGZHOU DATIAN CNC MACHINE TOOL

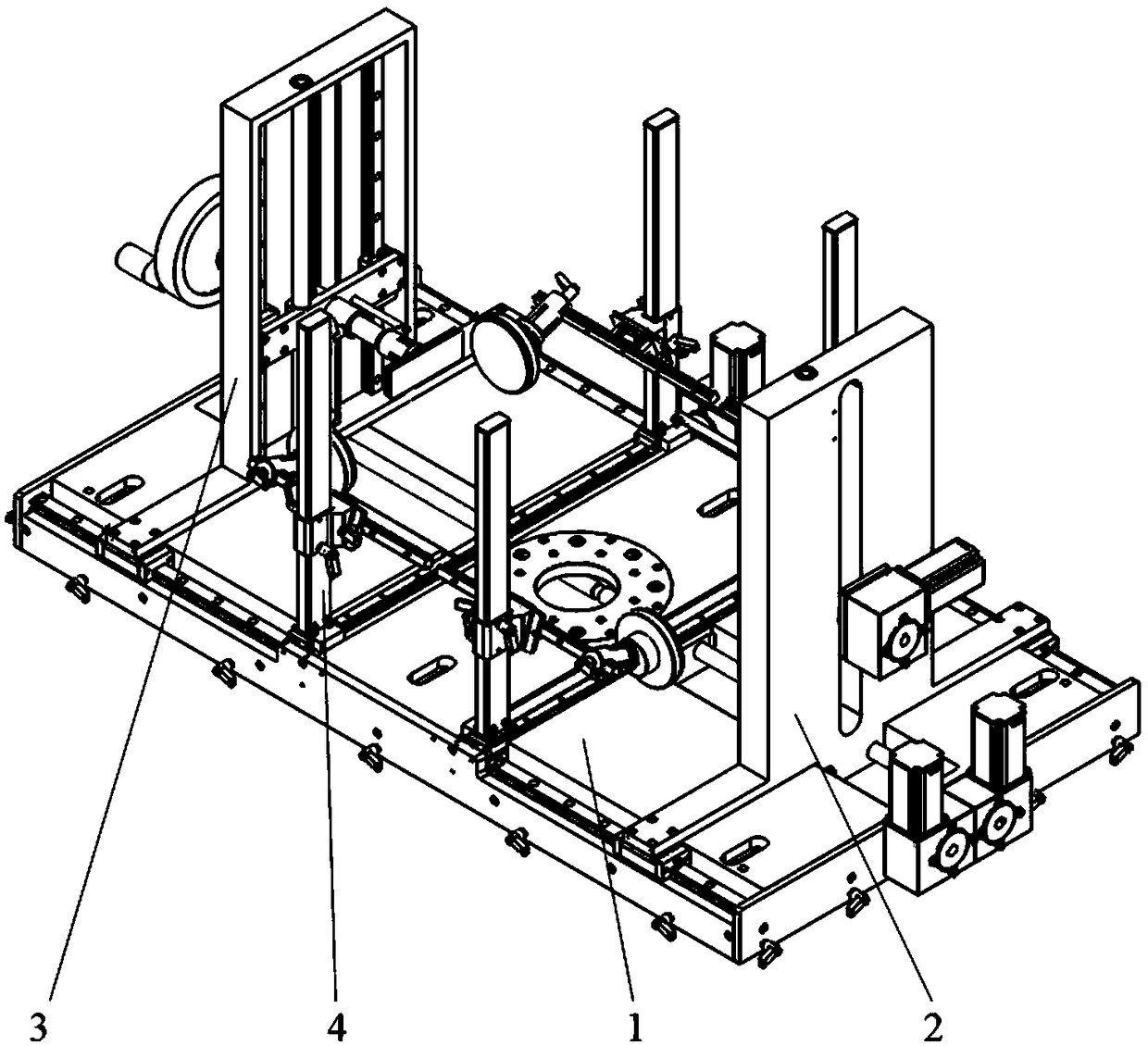

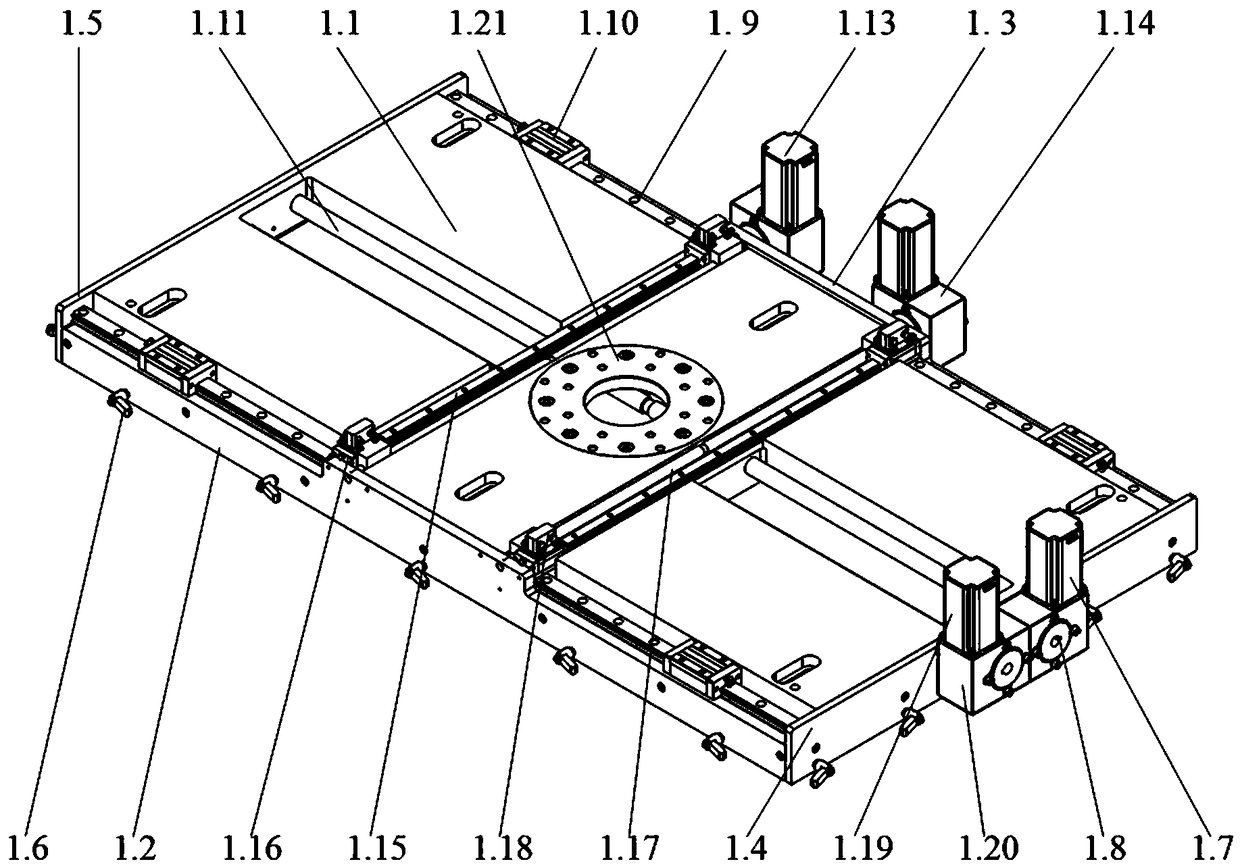

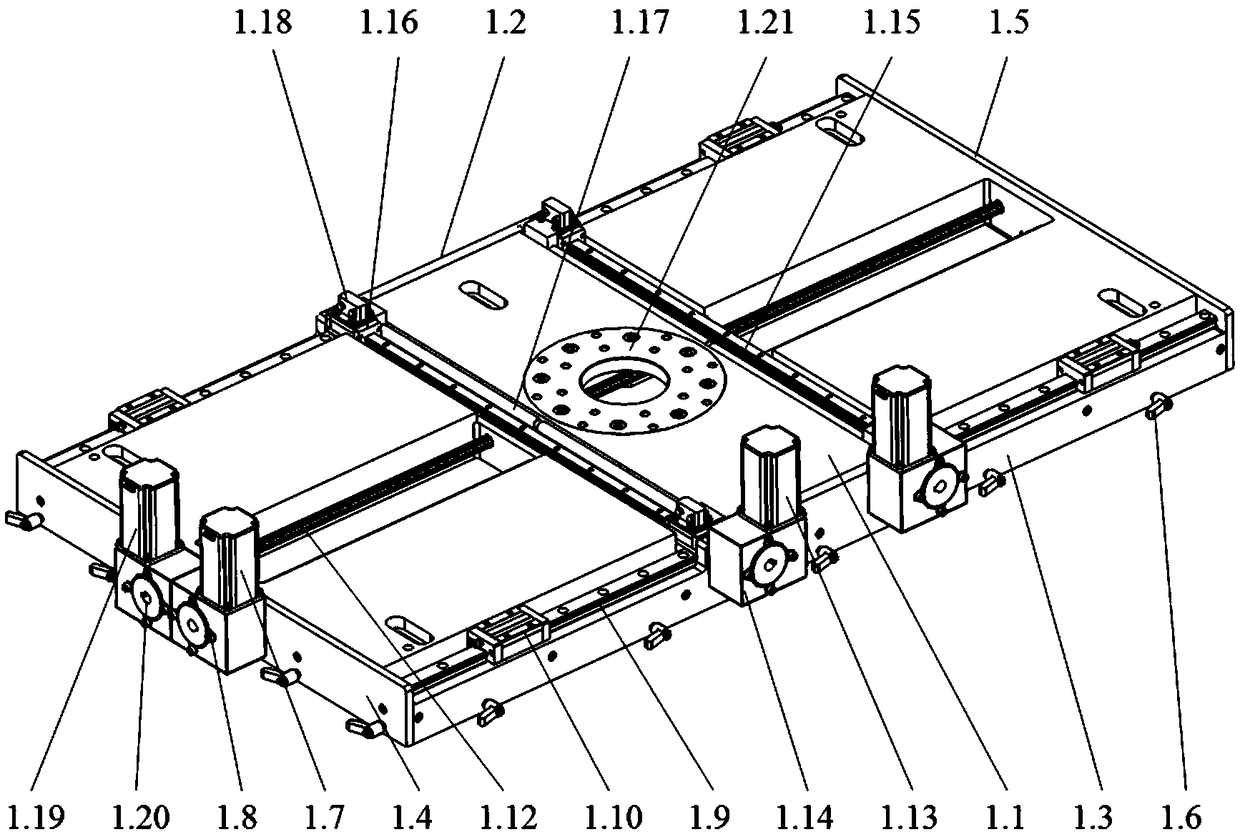

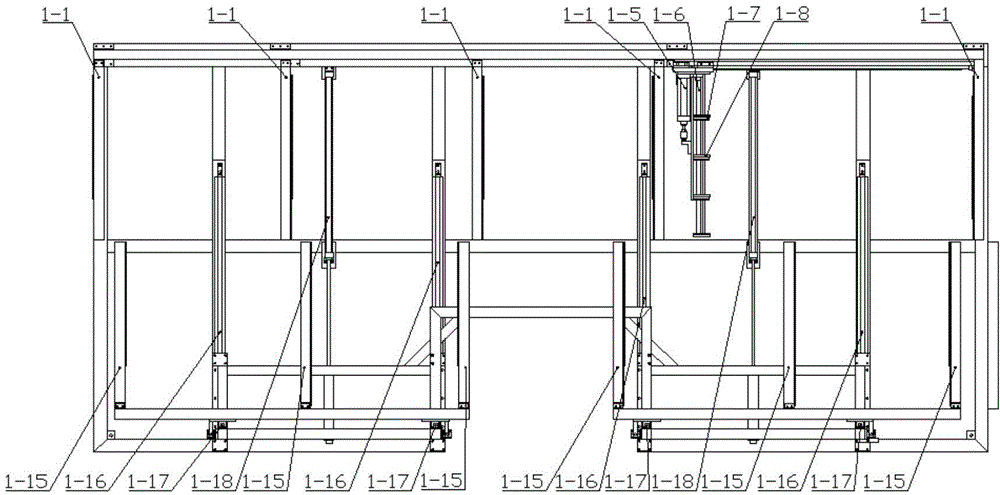

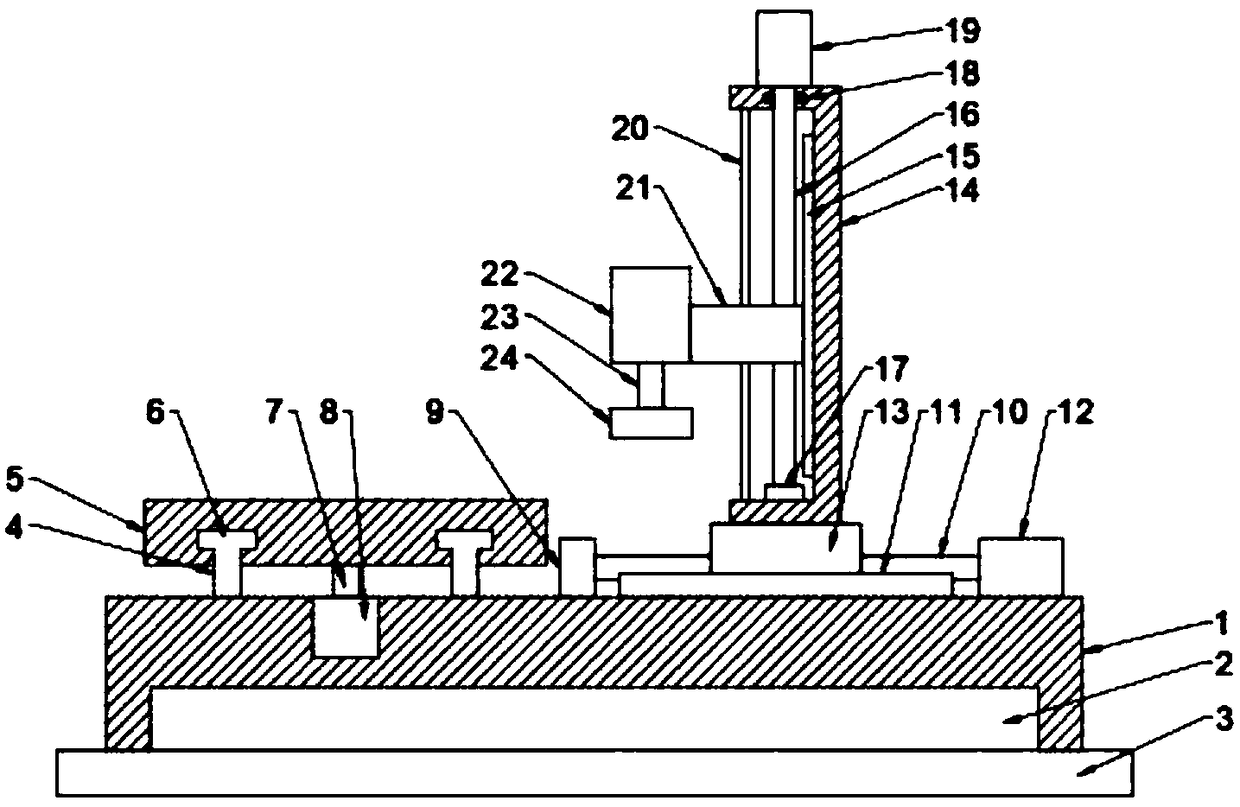

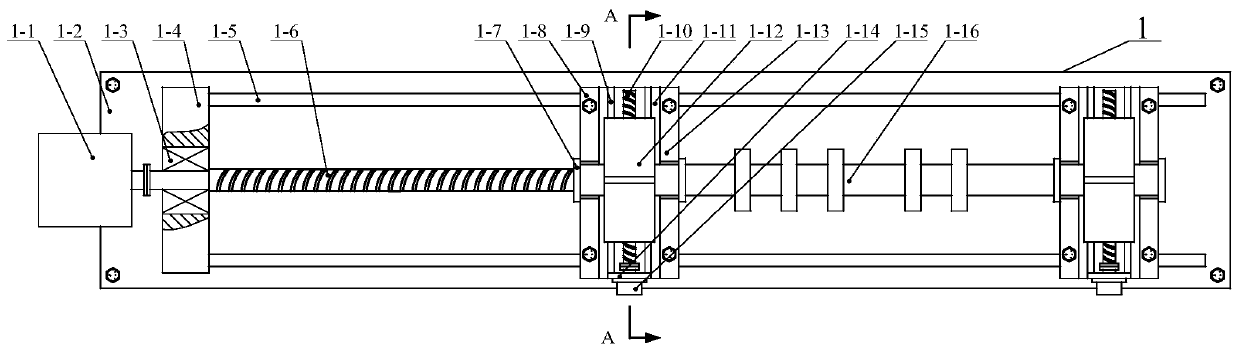

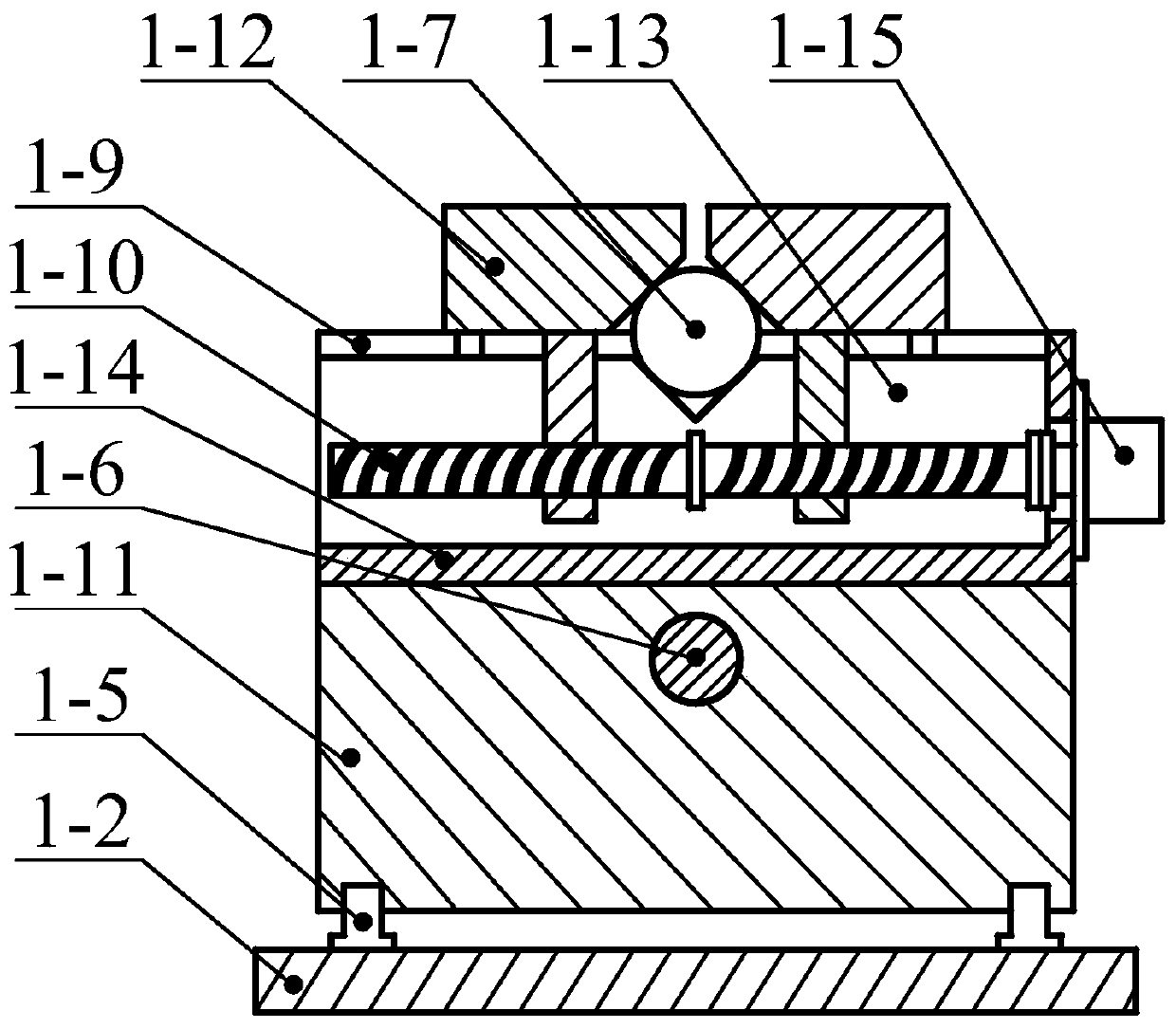

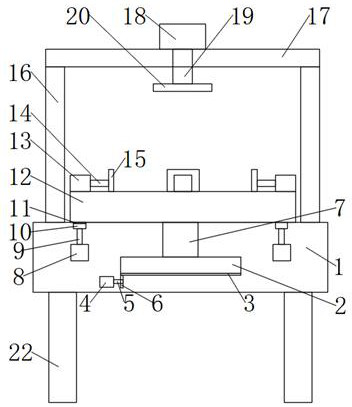

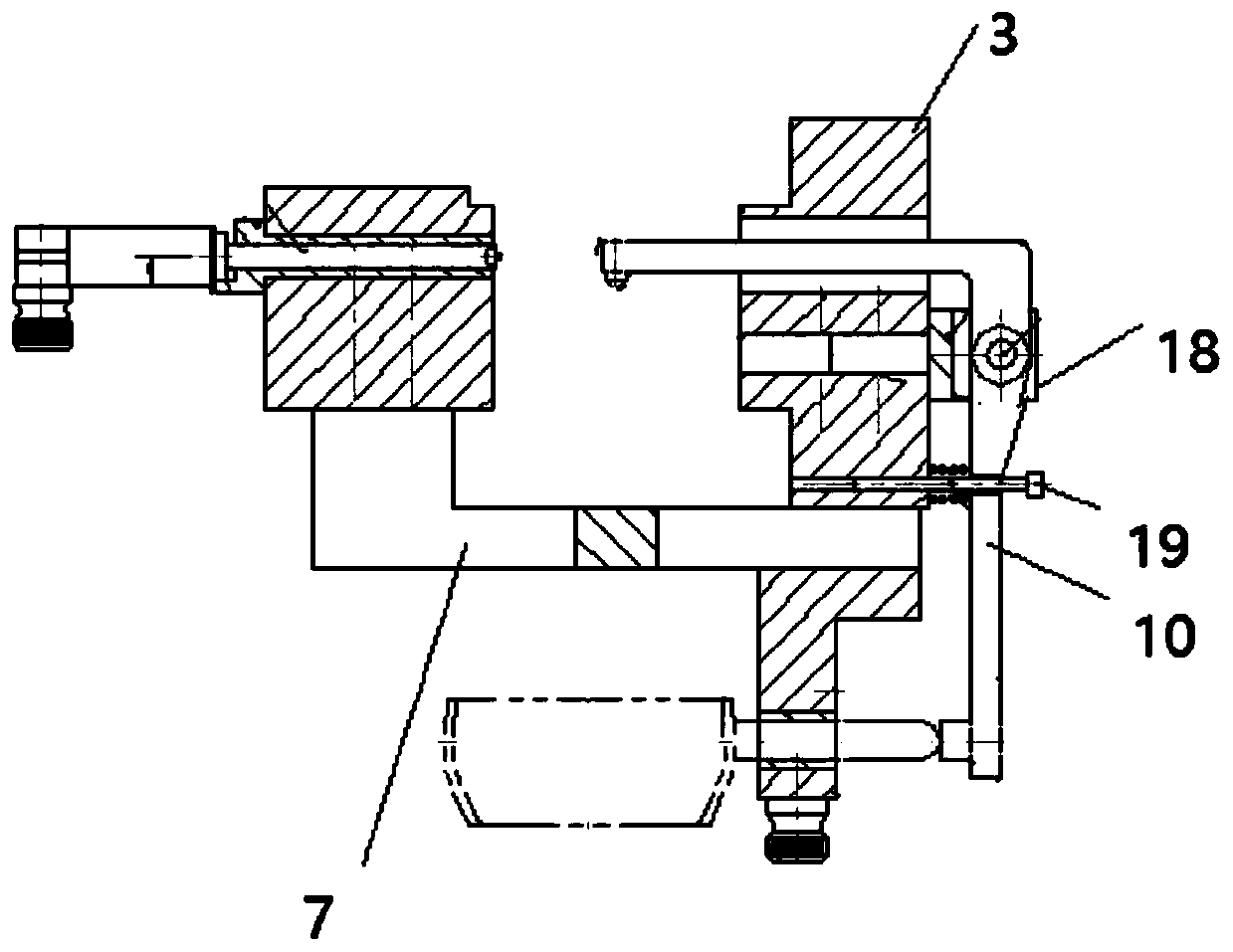

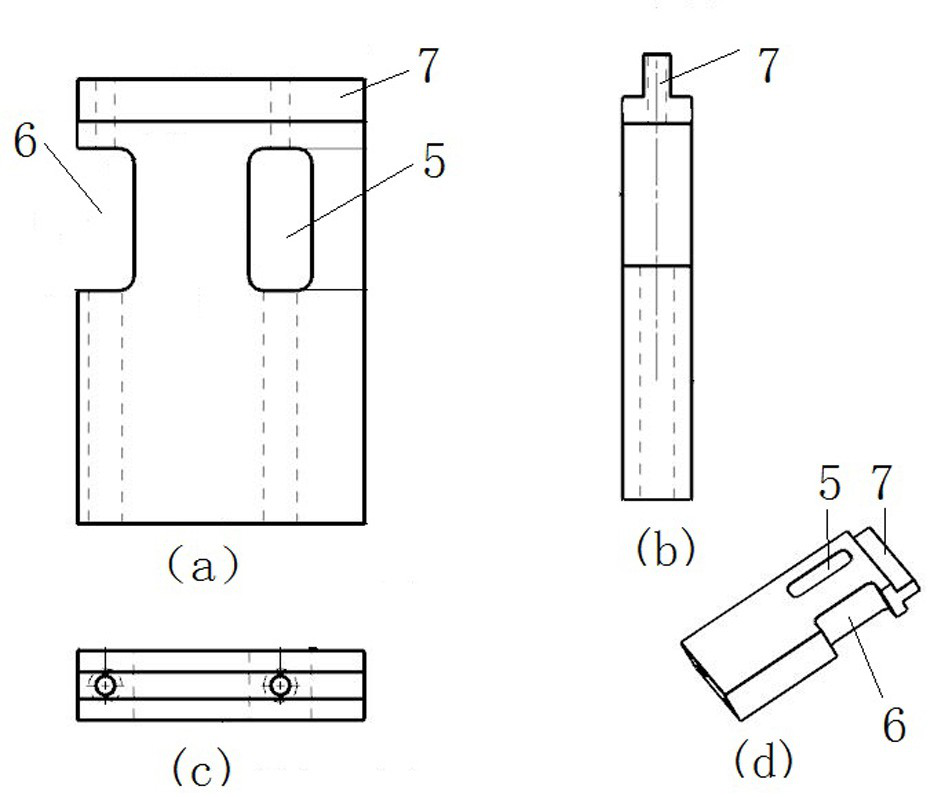

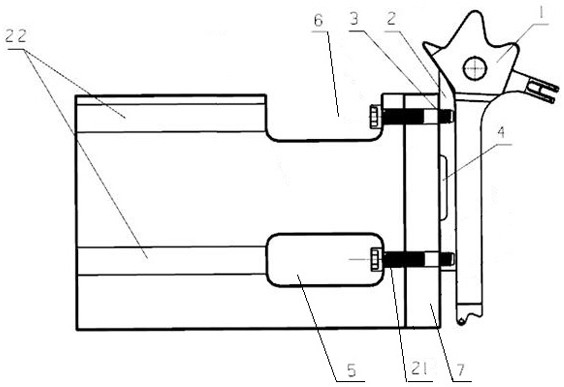

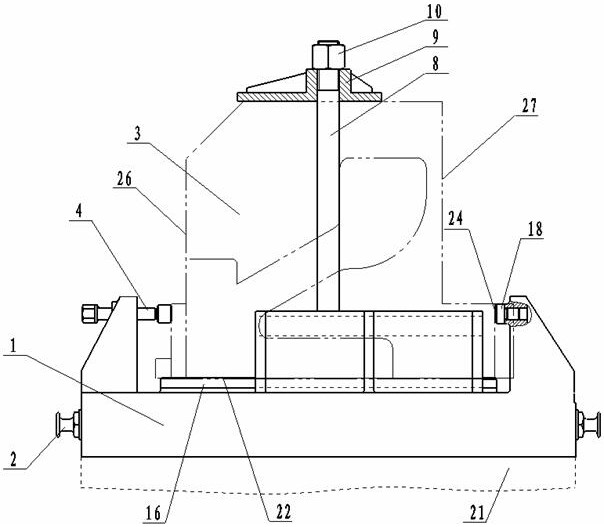

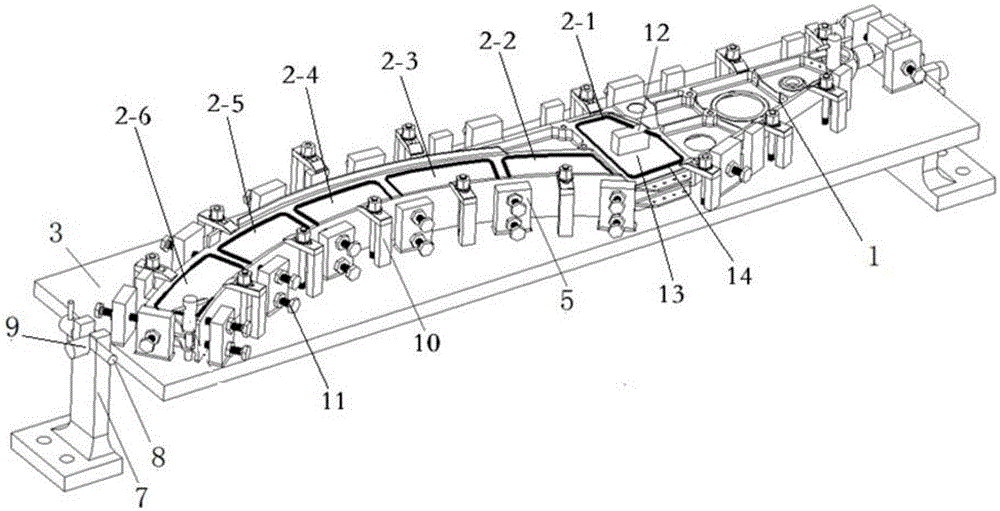

Pressing mechanism for airplane titanium alloy part processing tool table

ActiveCN108637724AGood repeatabilityImprove consistencyPositioning apparatusMetal-working holdersMotor driveEngineering

The invention relates to a pressing mechanism for an airplane titanium alloy part processing tool table, in particular to an auxiliary device for a machine tool processing part. The pressing mechanismcomprises four parts, which are separately a pedestal regulating and fixing mechanism, a left side lifting pressing mechanism, a right side lifting pressing mechanism and an X-direction pressing mechanism, wherein the left side lifting pressing mechanism and the right side lifting pressing mechanism are mounted and fixedly arranged on the pedestal regulating and fixing mechanism, and define a threaded-transmission and spline-transmission matching relationship with the pedestal regulating and fixing mechanism; and the X-direction pressing mechanism is mounted and fixed on the pedestal regulating and fixing mechanism. The pressing mechanism can be manually and quickly regulated, and a motor drives equipment to realize automatic regulation on a clamping dimension and a clamping position as well as clamping with set load; and the motor drives blank to lift and rotate, so that multi-surface processing is realized.

Owner:XIAN AIRCRAFT IND GROUP

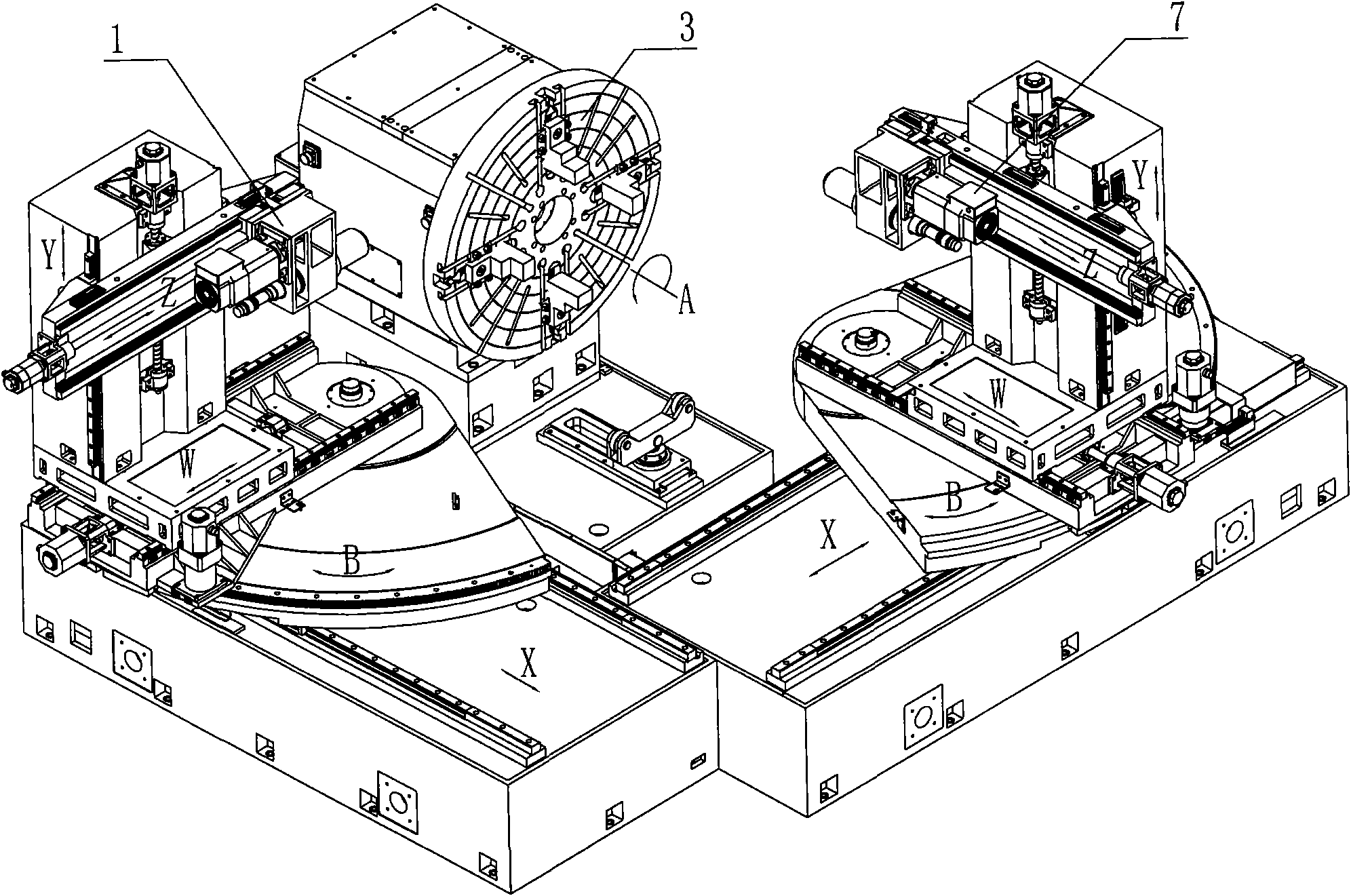

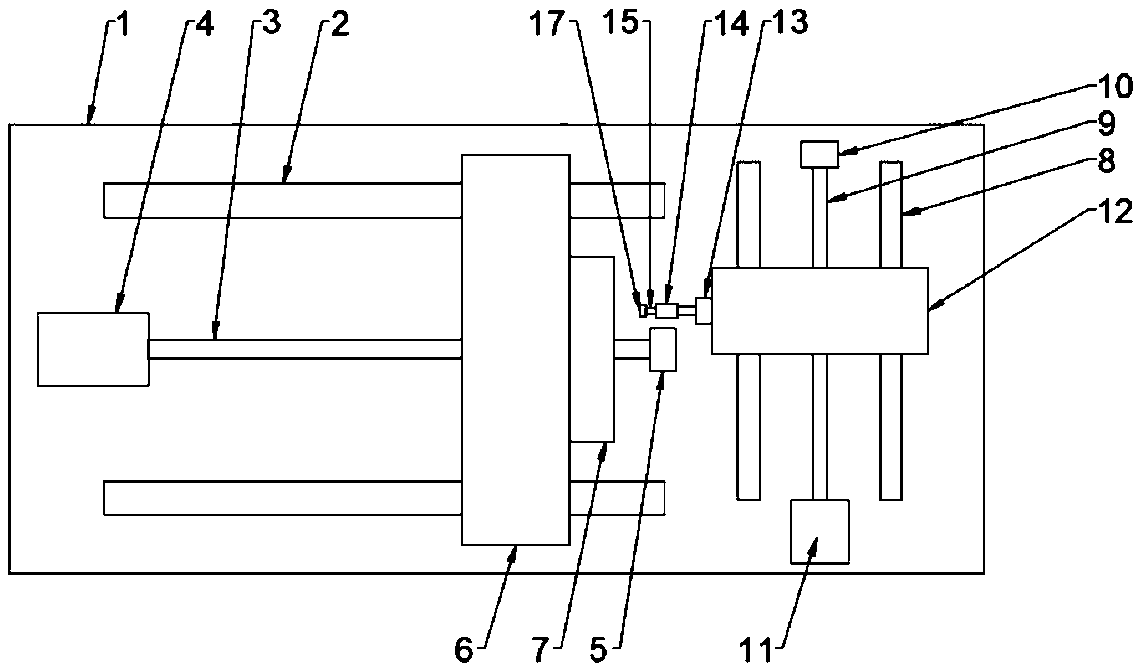

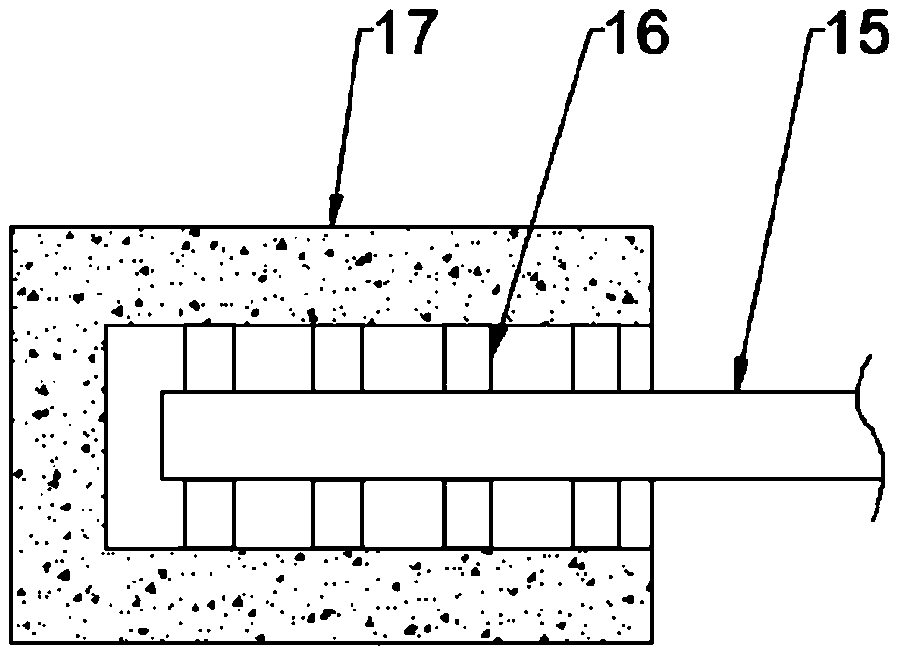

Engine cylinder head numerical control machine for floating ship

The invention discloses an engine cylinder head numerical control machine for a floating ship, comprising an electrical control system, a numerical control system, a hydraulic system, a chip removal system, lubrication system and a cooling filter system, as well as respective independent devices: a radial processing unit, an axial processing unit, and a high-accuracy axis A indexing fixture, which is characterized in that three devices are combined into a special tool through a set of the electrical control system, the numerical control system, the hydraulic system, the chip removal system, the lubrication system and the cooling filter system; the radial processing unit and the axial processing unit have the same structure; Z and W are two parallel numerical control linear axes which are in a horizontal level with ground along the axial direction of tools; axis X is parallel to the ground and vertical to axis Y and axis Z, the axis Y is vertical to the ground and perpendicular to the axis Z and axis W, B is a numerical control rotating axis, the axis of rotation of the axis B is parallel to the axis Y, the fixture is fixed on axis A, and the indexing fixture on the axis A is the position reference axis of five directions of the axis X, axis Y, axis Z, axis W and axis B. The machine can realize one-time clamping, and simultaneously complete the work of slot hole drilling and milling from different radial and axial angles and positions for workpieces with high weight.

Owner:沈阳机床成套设备有限责任公司 +1

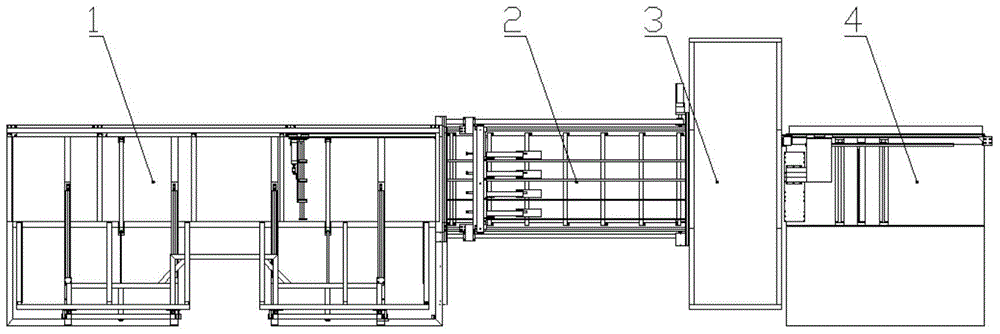

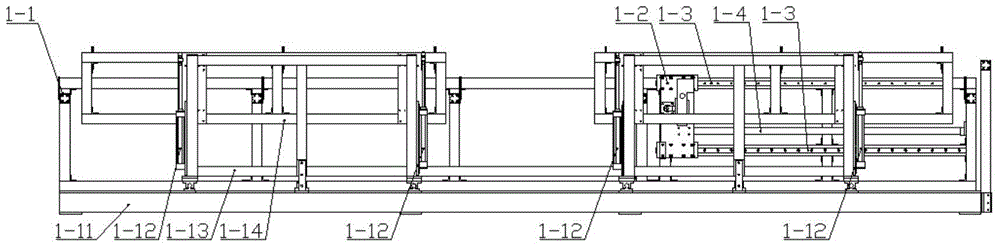

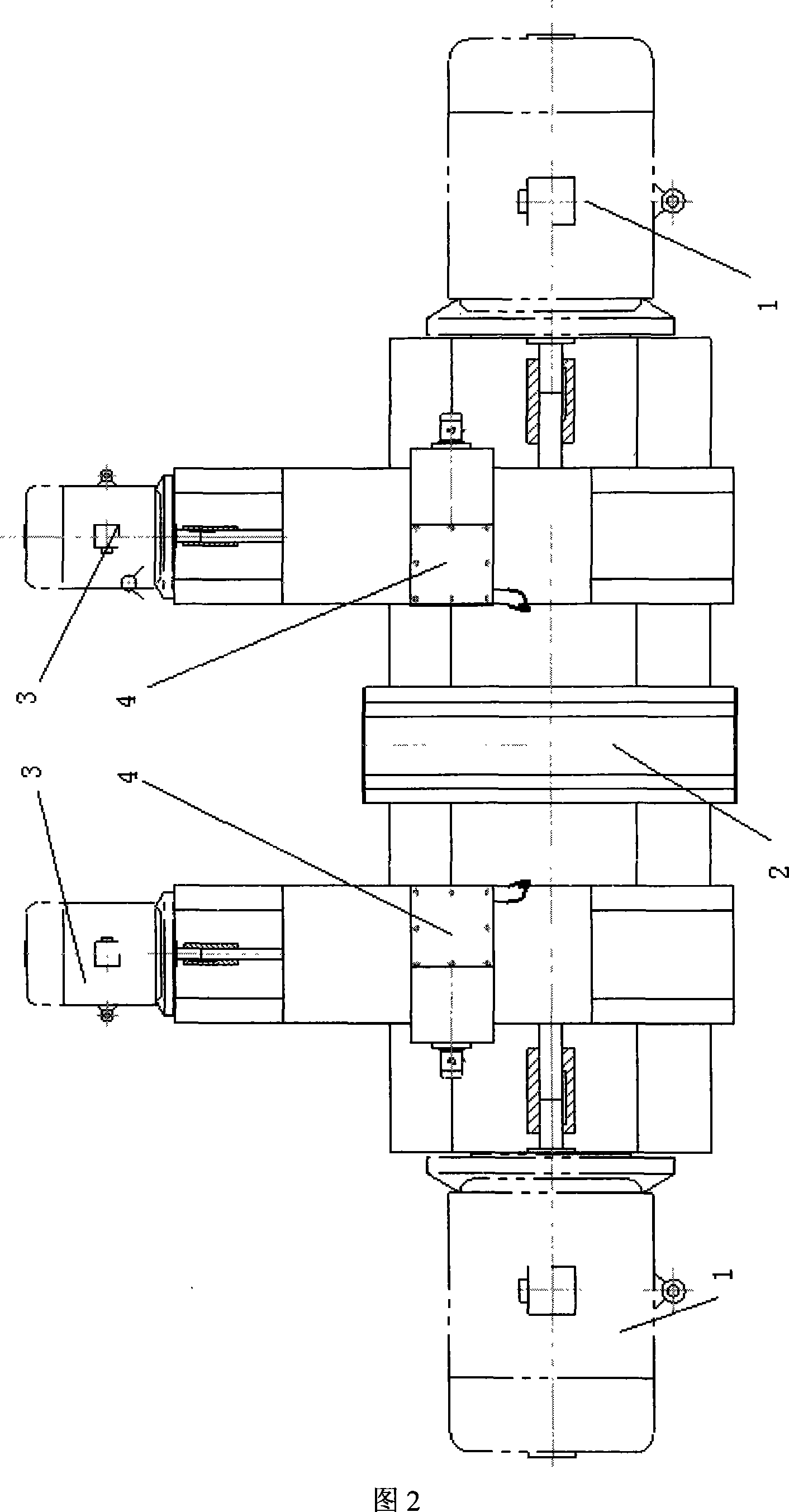

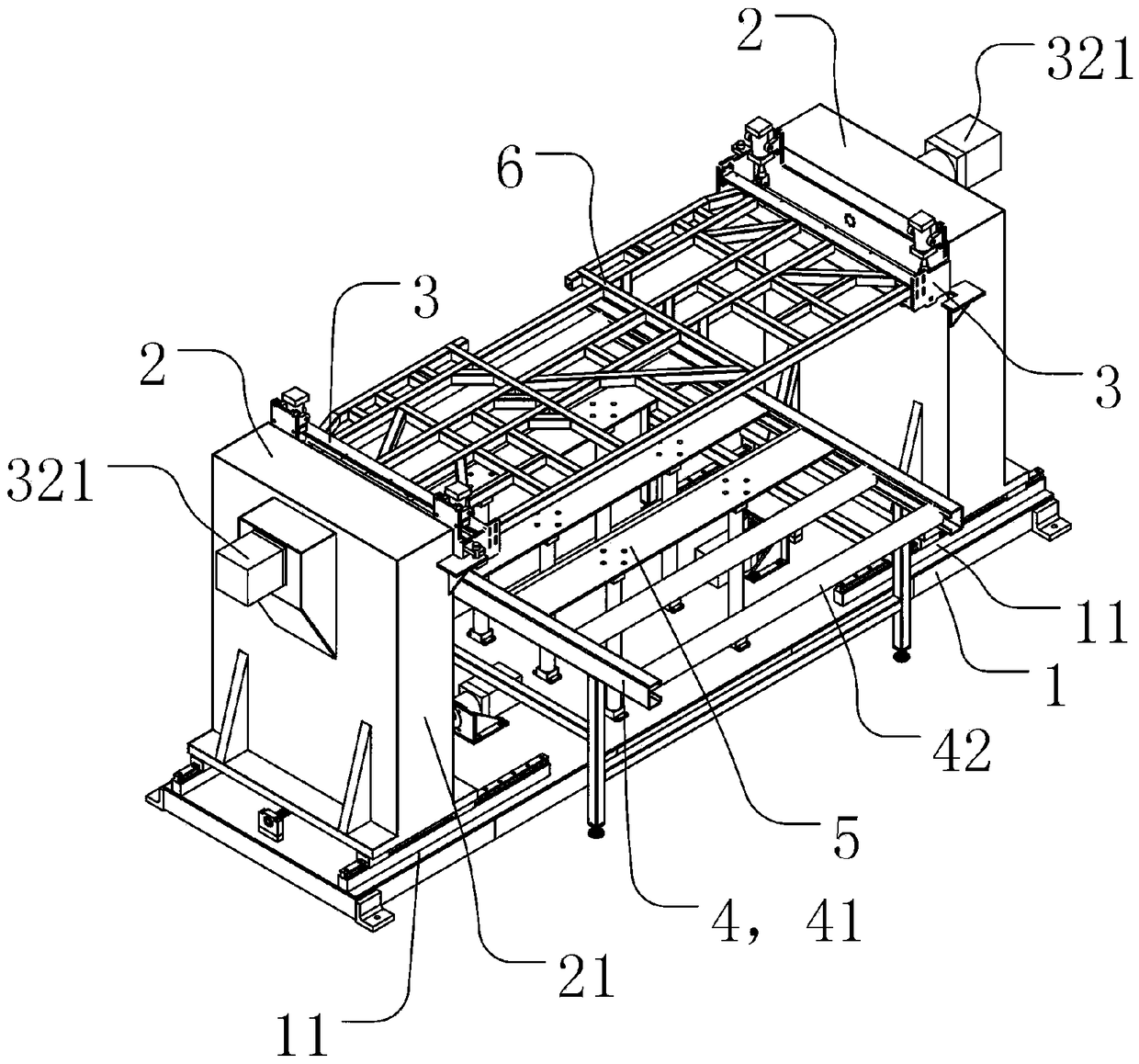

Profile saw-cutting equipment

ActiveCN104907625AImprove work efficiencyImprove stabilityMetal sawing devicesMetal working apparatusFixed frameManipulator

The invention discloses profile saw-cutting equipment comprising a loading device, a feeding device, a saw-cutting device and an unloading device which are sequentially arranged according to a profile feeding direction. The feeding device comprises a rack, the loading device is mounted at the head of the rack, a manipulator fixing frame is mounted on the upper portion of the rack, multiple manipulators used for clamping a profile are mounted on the manipulator fixing frame, and the manipulator fixing frame slides back and forth along the rack to convey the profile to space below the saw-cutting device; the saw-cutting device comprises a saw head seat, a front saw head and a rear saw head which are in front-rear arrangement in the horizontal direction are mounted at the bottom of the saw head seat, central lines of the front saw head and the rear saw head form an angle of 45 degrees, the front saw head and the rear saw head are driven by respective cylinders to realize feeding or returning along a direction perpendicular to a direction in which the respective central lines are and are driven by respective motors to rotate respectively, and the unloading device comprises a discharging platform communicated with space below the saw-cutting device.

Owner:山东辰禾智能装备有限公司

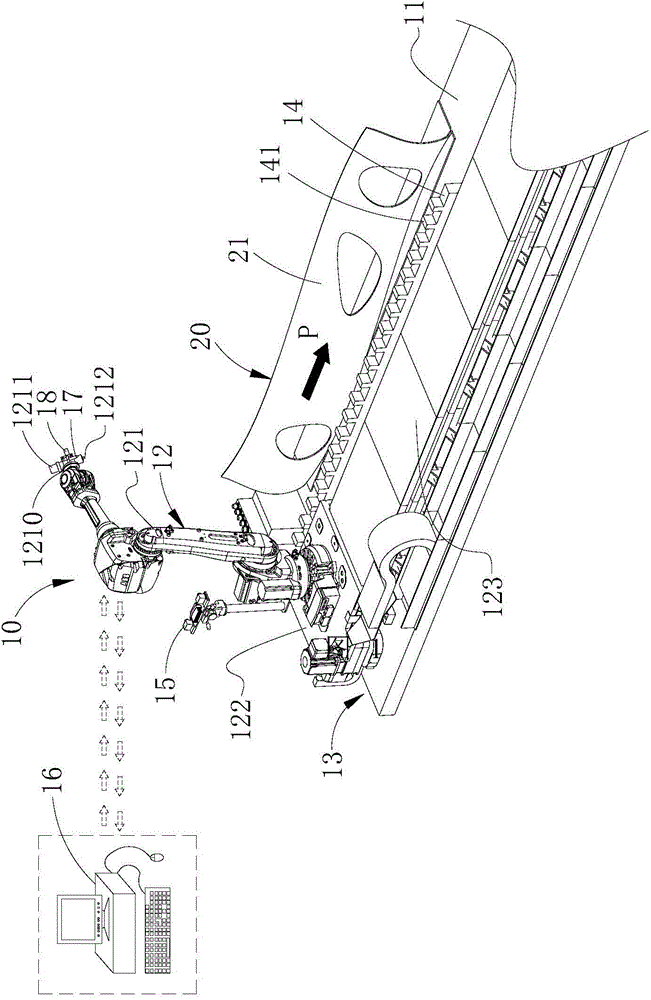

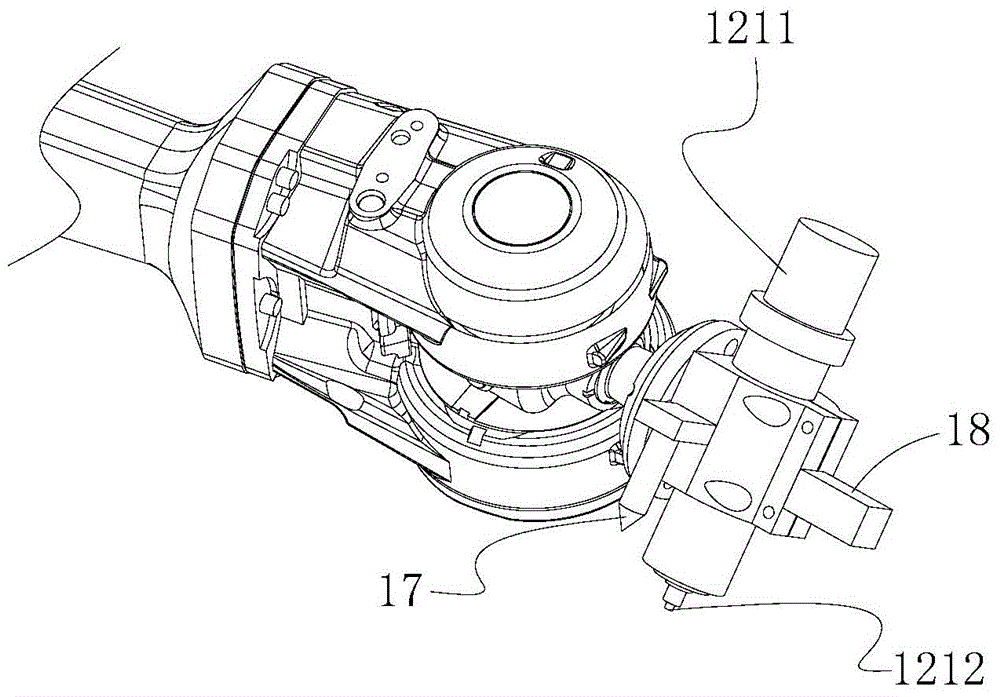

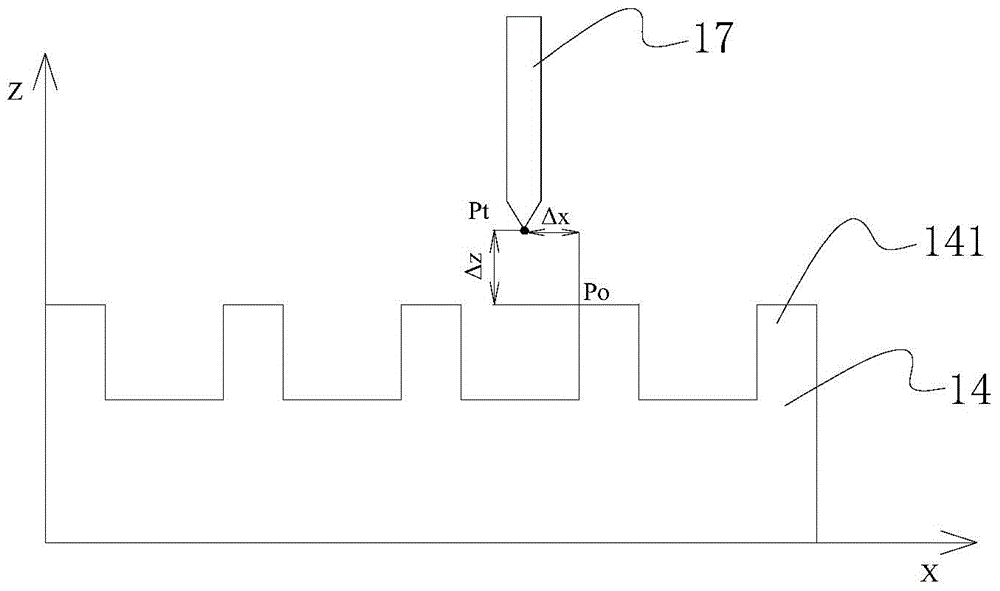

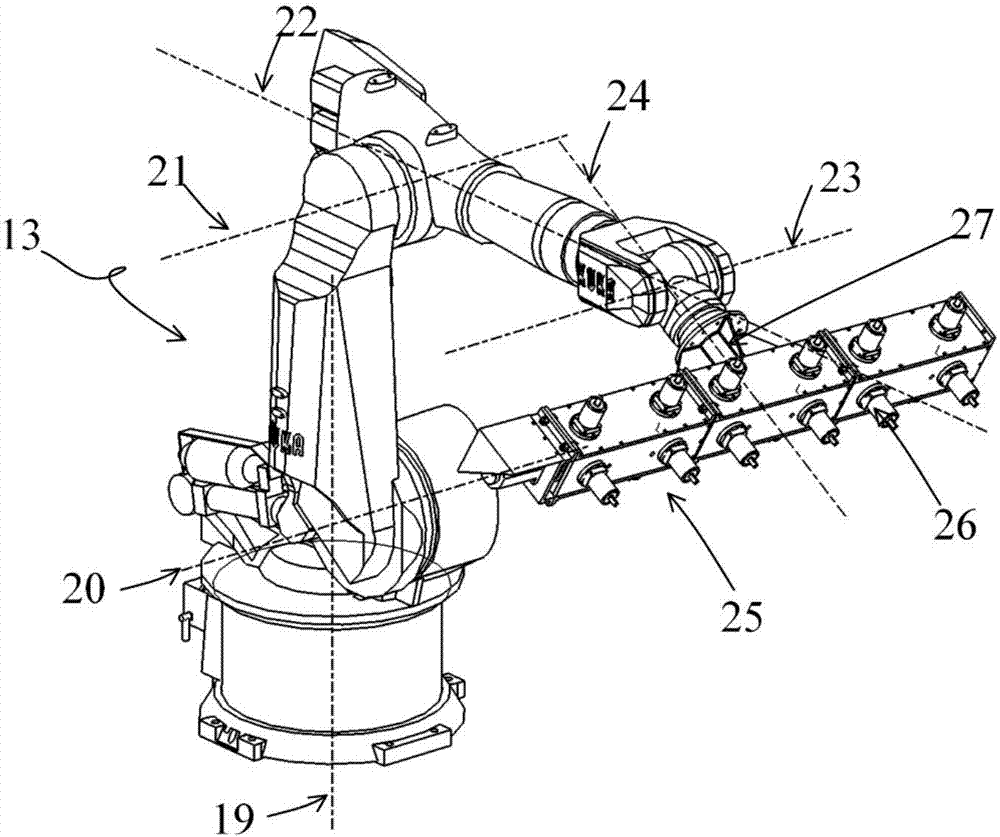

Machining method and machining equipment for parts with curved surfaces

ActiveCN104858712AReduce machining errorsImprove machining accuracyProgramme-controlled manipulatorAutomatic control devicesData analysisImaging data

The invention provides a machining method for parts with curved surfaces. The machining equipment is provided with a robot, a posture calibration block, a three-dimensional scanning device and a host computer, and the machining method comprises the following steps: scanning a part I with a curved surface I and the posture calibration block with the three-dimensional scanning device; sending the obtain image data I to the host computer, so as to conduct reverse modeling and data analysis on the image data I, and further obtain a first relative deflection value; machining the part I; replacing the part I with another part II with a curved surface II after the part I is machined; scanning the part II and the posture calibration block with the three-dimensional scanning device; sending the obtain image data II to the host computer, so as to conduct reverse modeling and data analysis on the image data II, and further obtain a second relative deflection value; calculating the deflection error between the second relative deflection value and the first relative deflection value; carrying out compensation on the robot with the host computer according to the deflection error; machining the part II; repeating the above steps till all the parts are machined. The invention further provides machining equipment for the parts with the curved surfaces.

Owner:YUANMENG PRECISION TECH SHENZHEN INST

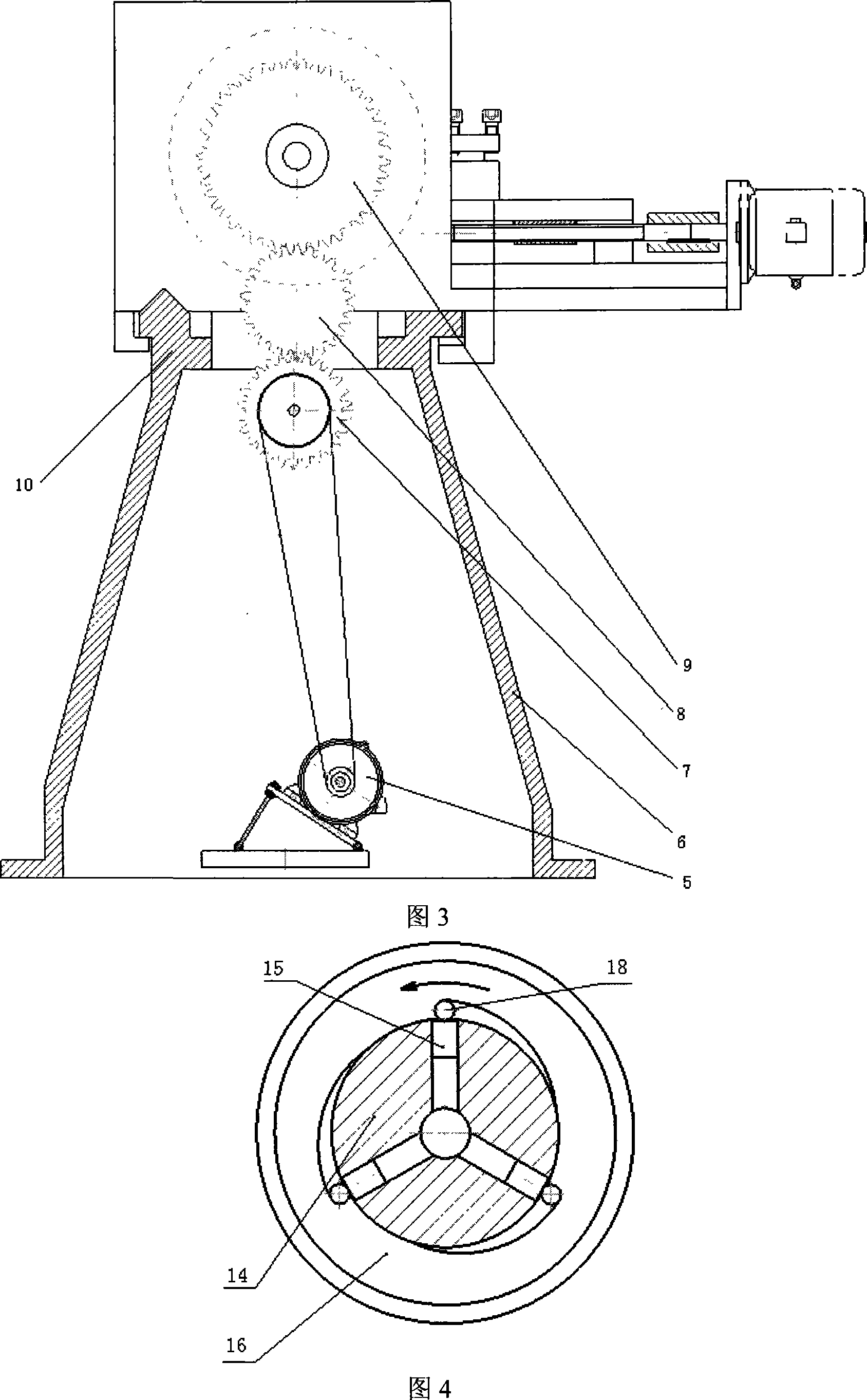

Turbine assembly drill jig

InactiveCN104511765ARealize one clampingGuaranteed accuracy requirementsPrecision positioning equipmentPositioning apparatusTurbineDrill

The invention discloses a turbine assembly drill jig. The turbine assembly drill jig comprises a support base vertically mounted on a base, a rotating shaft horizontally penetrates the middle portion of the support base through a bearing and a bearing seat, a round plate for positioning the end surface of a turbine hub is mounted on the front portion of the support base on the rotating shaft, a grading plate for rotating the round plate for grading the turbine hub is mounted on the rear portion of the support base on the rotating shaft, a bending plate bent forwards is mounted at the upper end of the support base, and grooves for positioning the end surface of the turbine hub is arranged on the periphery of the round plate. Compared with the prior art, the turbine assembly drill jig can solve the problems that the accuracy of existing turbine hub drilling is difficult to ensure and the machining efficiency is low.

Owner:LIUZHOU GUOSHUN MECHANICAL MFR +1

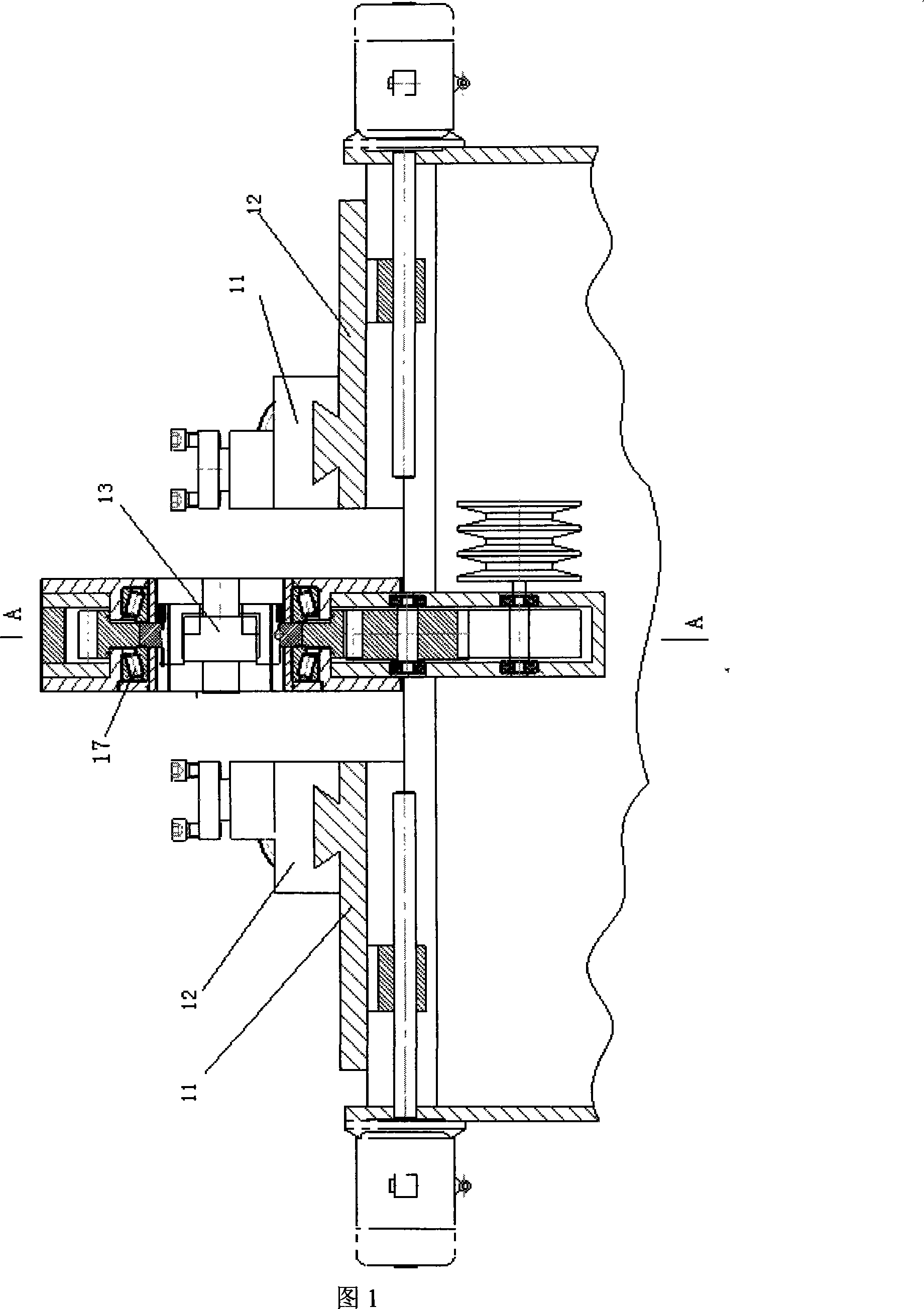

Double-faced processing combined machine tool

InactiveCN101168235AImprove machining accuracyImprove work efficiencyDriving apparatusMetal working apparatusMotor driveEngineering

The invention relates a machine bed capable of simultaneously turning and drilling the double face of a work piece of a mental shaft, tube, disc and the like. The machine bed comprises a body and a box fixed on the body, two big slide boards are respectively arranged on the body which is positioned on the two sides of the box, the two big slide boards are respectively connected with a first motor and a second motor 1, a small board is respectively disposed on the two big slide boards, a knife carrier is respectively fixed on the two small slide boards which are respectively connected with a third motor and a fourth motor, a fifth motor drives a sleeve to rotate through a gear mechanism, the box and the sleeve are connected through a bearing, the sleeve drives a main shaft through a rolling shaft, a clamp device is mounted with the main shaft realizing the effect of automatically clamping work pieces, and the clamp device can also be made to automatically clamp and loose without stopping a vehicle. The invention can achieve the simultaneous multi-position machining at the two ends of the work piece, thereby promoting machining accuracy and efficiency, consuming a small amount of energy, reducing labor intensity and being in particular adaptable for mass production.

Owner:安团英

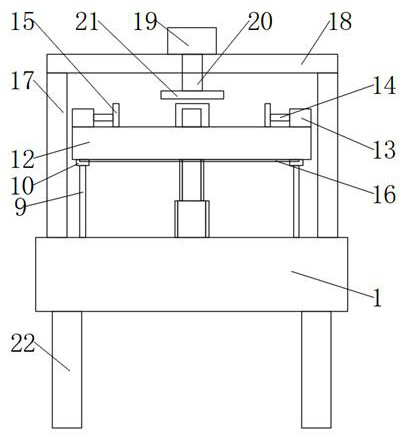

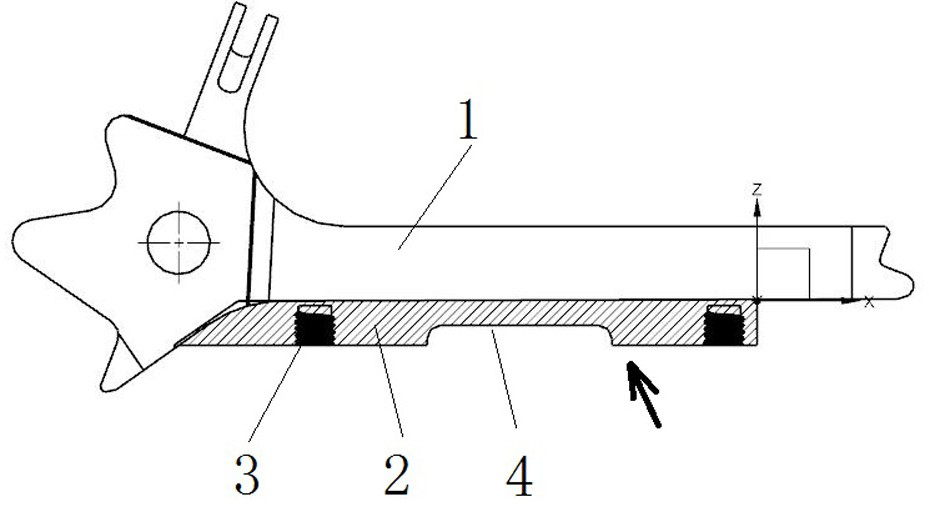

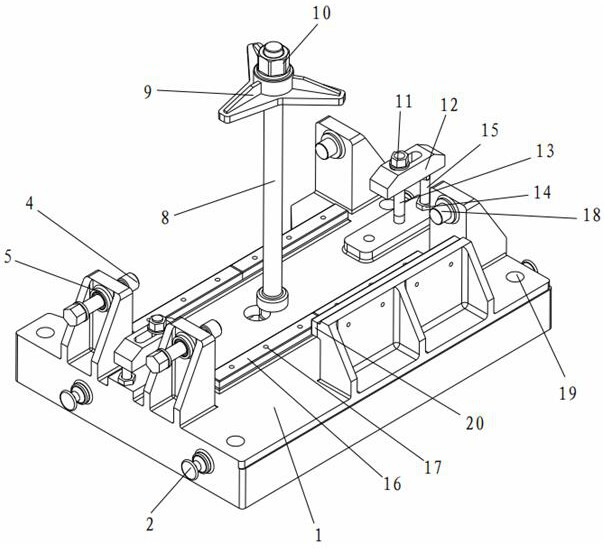

Base adjusting and fixing mechanism of aircraft titanium alloy part machining tool table

InactiveCN108673176AGood repeatabilityImprove consistencyLarge fixed membersPositioning apparatusMachine partsEngineering

The invention relates to a base adjusting and fixing mechanism of an aircraft titanium alloy part machining tool table. The mechanism is an auxiliary device of a machining part of a machine tool. Thedevice comprises four parts, namely a base adjusting and fixing mechanism, a left lifting tight pressing mechanism, a right lifting tight pressing mechanism and an X-direction tight pressing mechanism, wherein the left lifting tight compressing mechanism and the right lifting tight compressing mechanism are fixedly installed on the base adjusting fixing mechanism, and are connected with the base adjusting and fixing mechanism to form a threaded transmission and spline transmission cooperating relation; and the X-direction tight pressing mechanism is fixedly installed on the base adjusting andfixing mechanism. According to the mechanism, rapid adjustment can be realized manually, automatic adjustment of the clamping size and position and tight clamping of a set load are achieved through amotor drives the equipment, a blank is driven by the motor to ascend or descend and rotate to realize multi-face machining.

Owner:XIAN AIRCRAFT IND GROUP

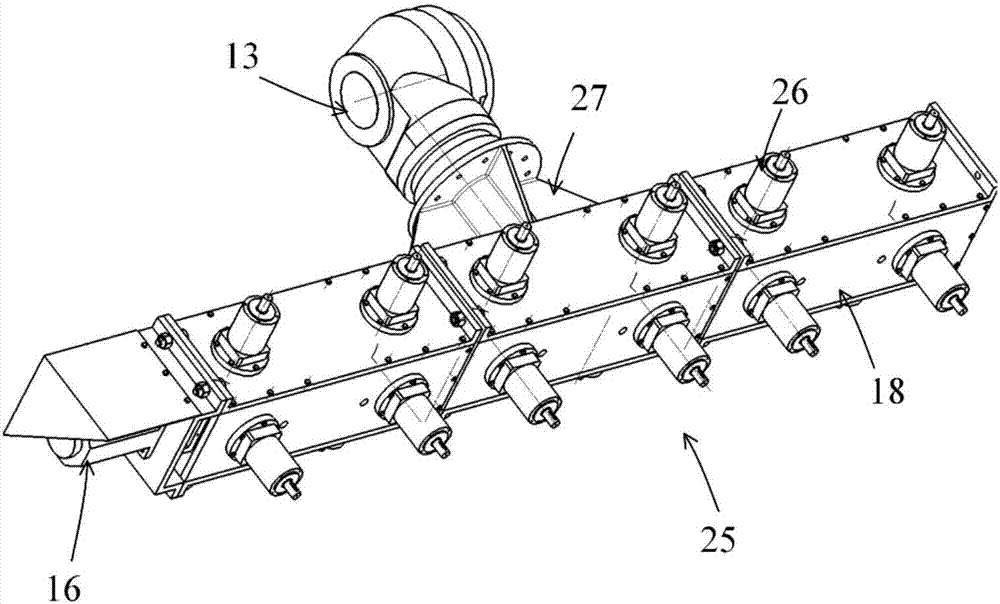

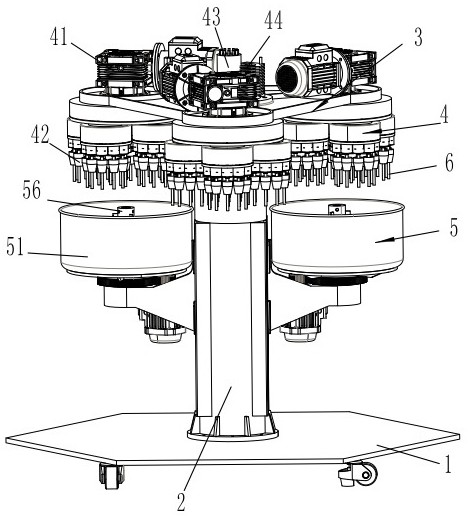

Modular array type multi-head end effector

ActiveCN107322468ARealize one clampingImprove work efficiencyGrinding machine componentsManipulatorElectric machineDrive shaft

The invention relates to a modular array type multi-head end effector. The modular array type multi-head end effector comprises a plurality of multi-rotary output shaft mechanism modules and a driving motor, wherein the plurality of multi-rotary output shaft mechanism modules are arranged in an array, and the plurality of multi-rotary output shaft mechanism modules are driven by the driving motor so as to be connected to an industrial robot through mechanical interfaces; the plurality of multi-rotary output shaft mechanism modules are coaxially arranged, heads and tails of driving shafts of two adjacent modules are connected by Oldham couplings, adapter flanges are arranged between two adjacent operating modules, and bolt connecting holes are formed in the flanges; motor power is transferred to the plurality of multi-rotary output shaft mechanism modules which are arranged in the array by the driving motor, and an output shaft of the driving motor is connected with input shafts of the plurality of multi-rotary output shaft mechanism modules by Oldham couplings; and bolt holes are respectively formed in both sides of the mechanical interfaces, and the end effector is connected to the robot in a bolt connecting mode.

Owner:厦门市瑞尔兰科技有限公司

Crystal ware polishing device

InactiveCN108857698AShorten processing timeImprove processing efficiencyEdge grinding machinesGrinding carriagesMotor shaftMachining process

The invention discloses a crystal ware polishing device which comprises a base and a support. A first motor is embedded into the left side of the top end face of the base, a first rotating shaft is fixedly connected to a motor shaft of the first motor, a first guide rail and two second guide rails are arranged at the top end of the base, a working table matched with the first guide rail is fixedlyconnected to the top end of the first rotating shaft, a first lead screw is arranged between the two second guide rails and is sleeved with a first moving base matched with the second guide rails, asupport is arranged at the top end of the first moving base, third guide rails are symmetrically arranged on the right side wall of an inner cavity of the support front and back, and a second lead screw is arranged between the two second guide rails. By means of the crystal ware polishing device, multi-angle polishing of products can be achieved, one-time clamping is achieved, and many machining processes can be completed as many as possible; the overall machining process is automatically completed by equipment, only manual feeding and discharging are needed, the machining time is greatly shortened, and the machining efficiency is greatly improved; and meanwhile, the product polishing uniformity is greatly improved, and the working strength is greatly reduced.

Owner:程敏

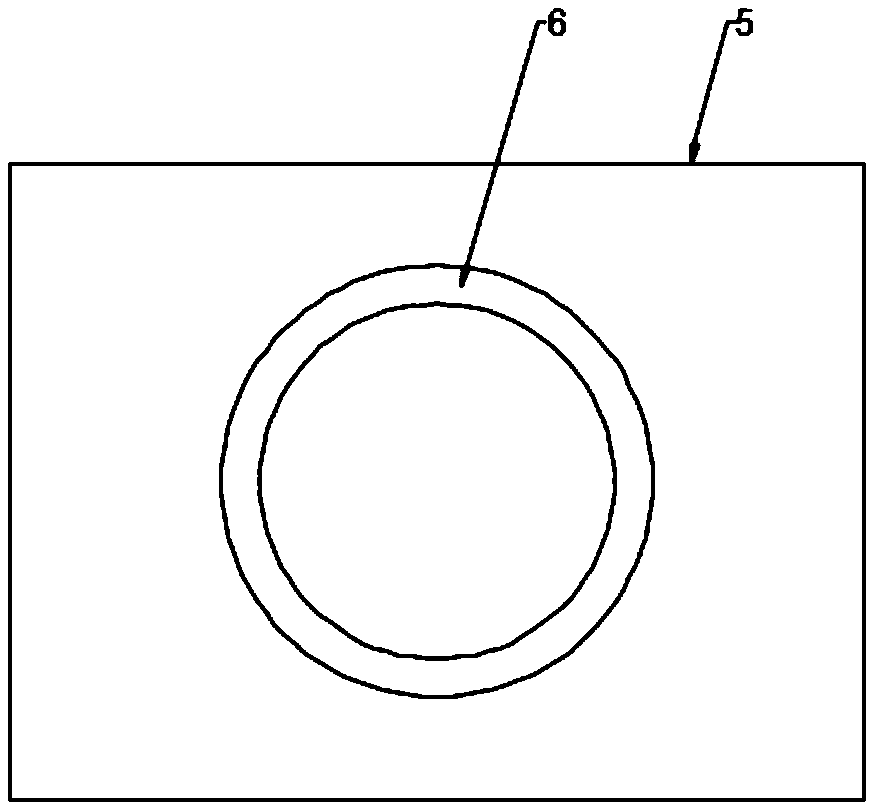

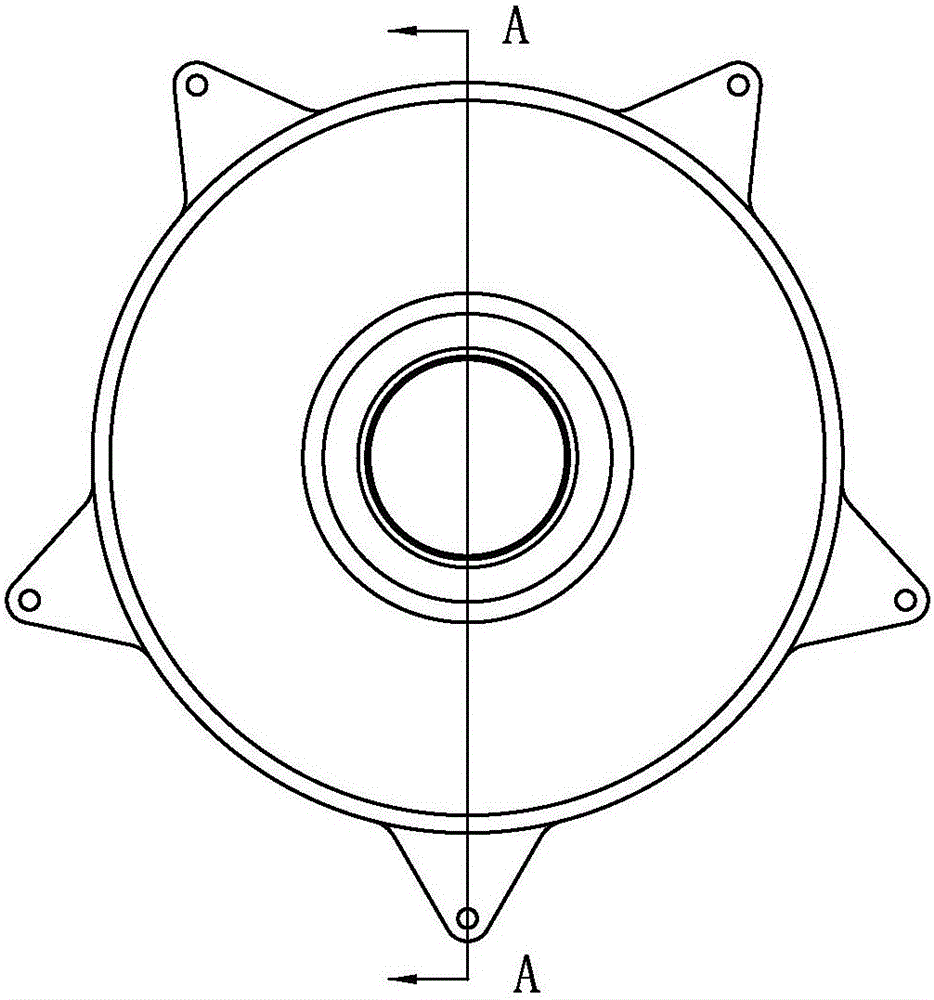

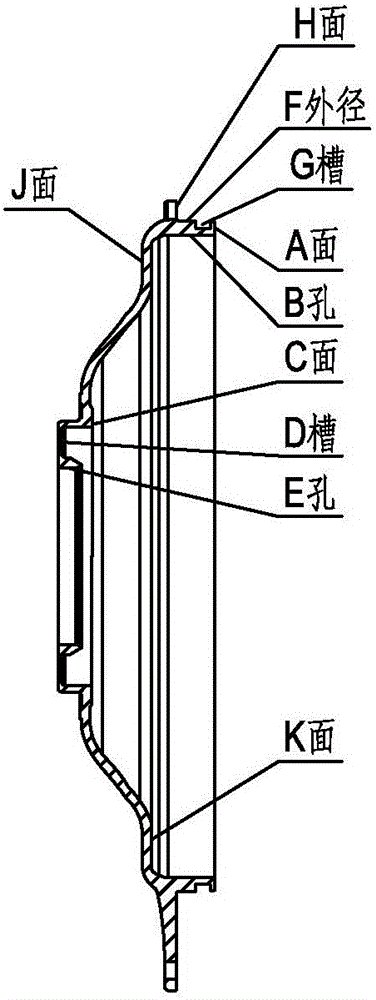

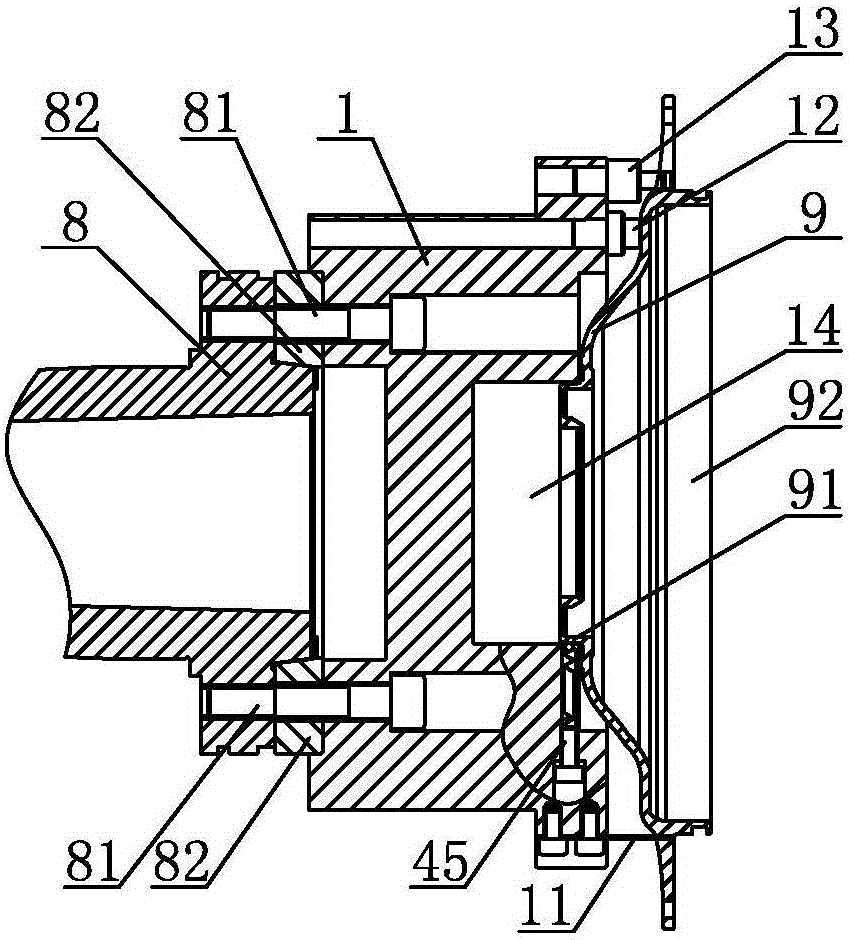

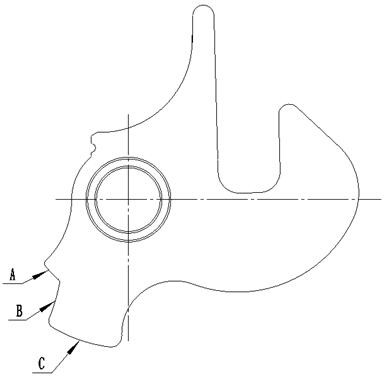

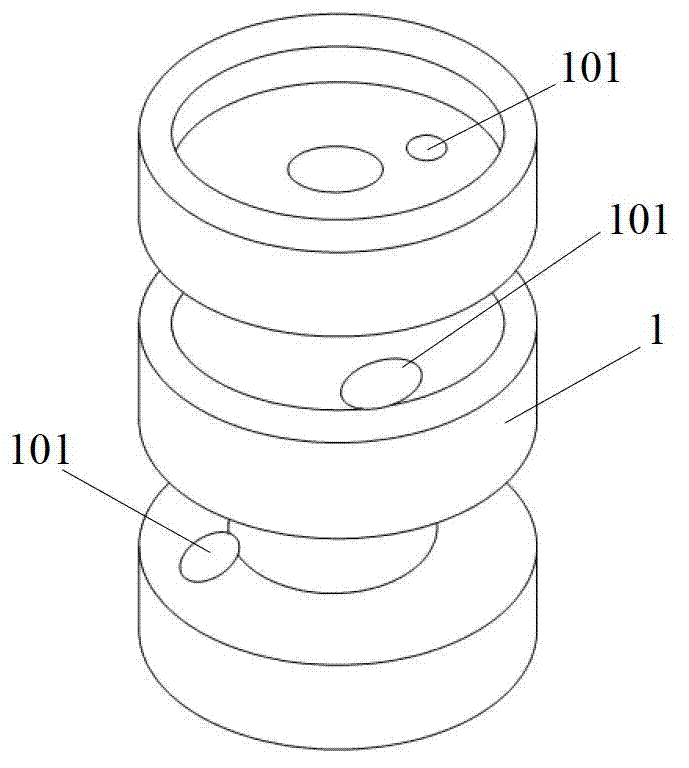

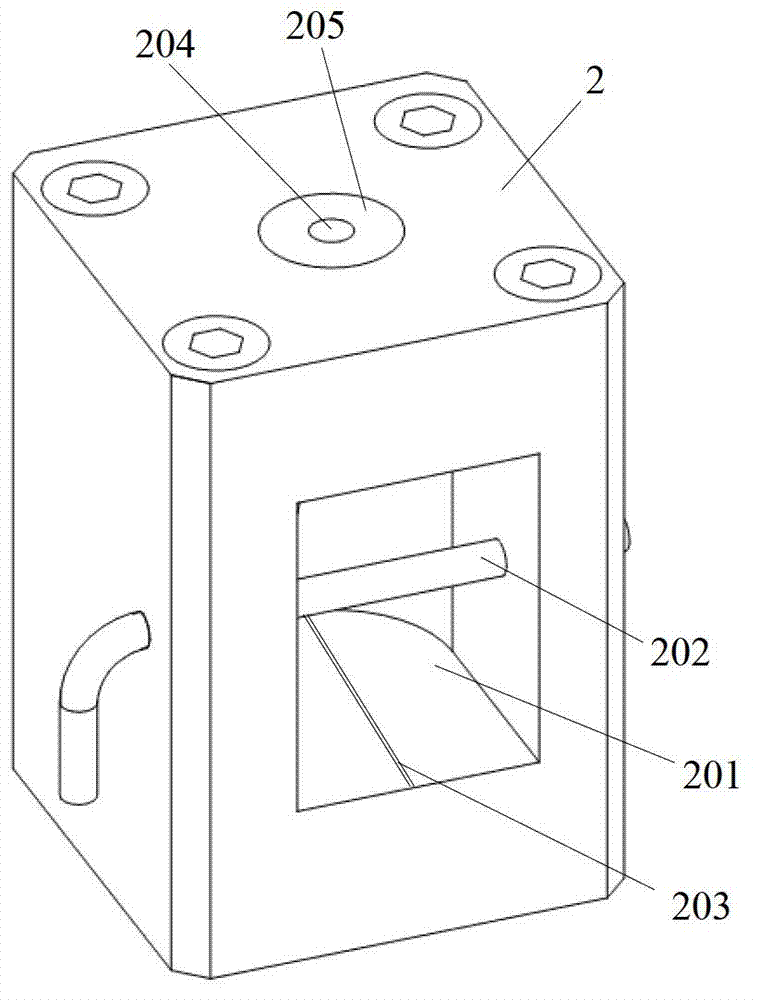

Clamping device for machining thin-walled disc part

ActiveCN105945624AImprove processing efficiencyRealize one clampingWork clamping meansPositioning apparatusHydraulic cylinderEngineering

The invention discloses a clamping device for machining a thin-walled disc part. Preliminary clamping and positioning of the part is performed by a clamp body, a support is pushed to move backwards along a linear rail by a hydraulic cylinder, and the part is pressed by a floating gland, so that primary clamping of the part is realized; after the part is clamped, a pneumatic angular positioning mechanism retracts, a spindle of a machine tool rotates, the part rotates together with a rotating gland, and then a surface A, a hole B, a groove G, an external diameter F and a surface H of the part can be machined by the machine tool; and so long as a turning tool of the machine tool extends into the rotating gland via an axial through hole, a surface C, a groove F and a hole E of the part can be machined. Compared with the traditional technology, the clamping device provided by the invention can reduce the clamping frequency of the part, can realize turning of all machined surfaces of the thin-walled disc part by clamping the part once, effectively avoids part collisions caused by turnover between procedures, can remarkably improve the machining efficiency of the thin-walled disc part, ensures the machining accuracy of the part, improves the machining quality of the product, reduces the cost and improves the benefit.

Owner:NINGBO HAITIAN PRECISION MASCH CO LTD

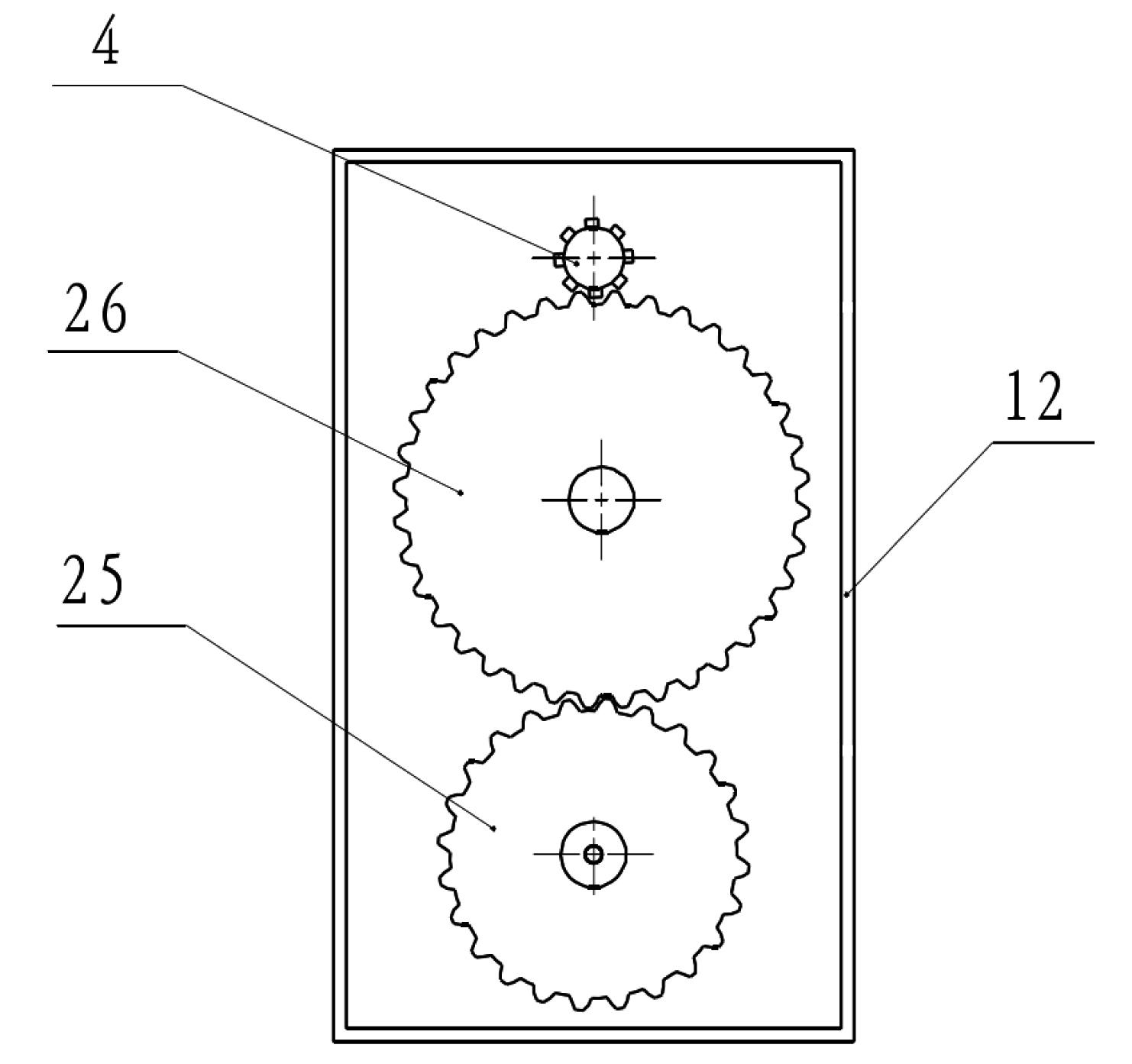

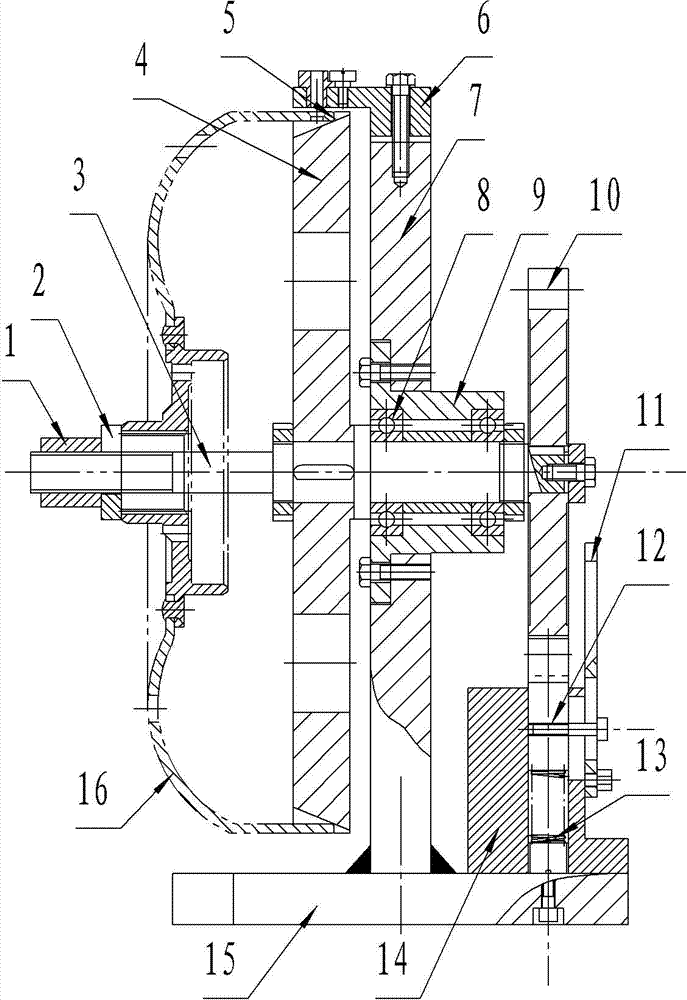

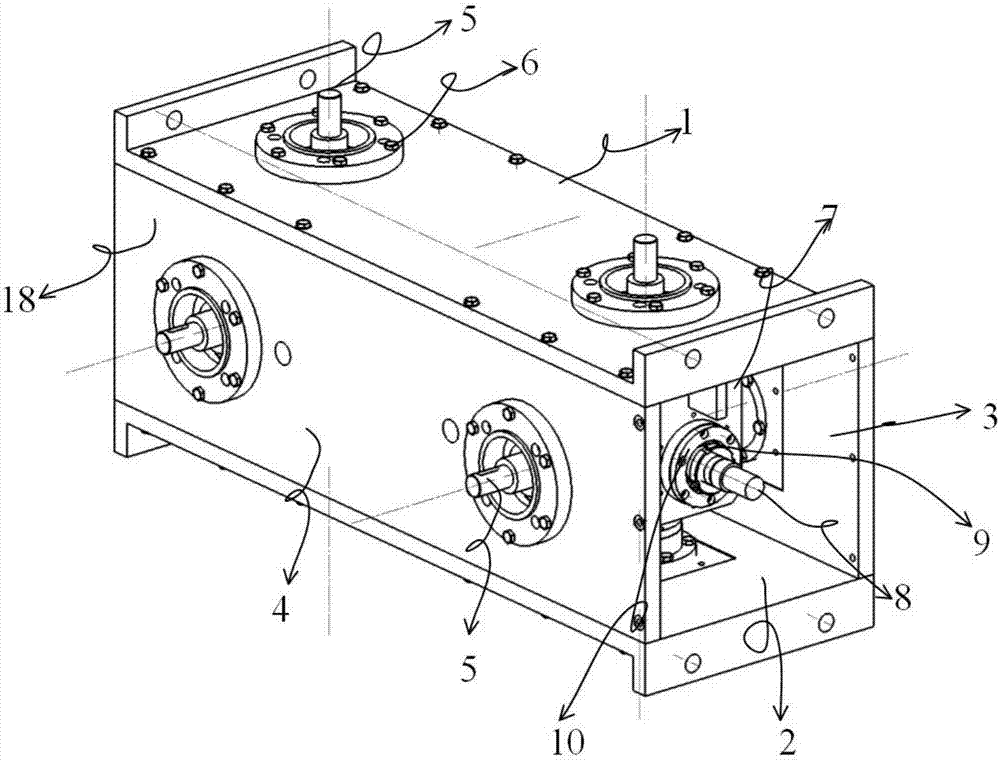

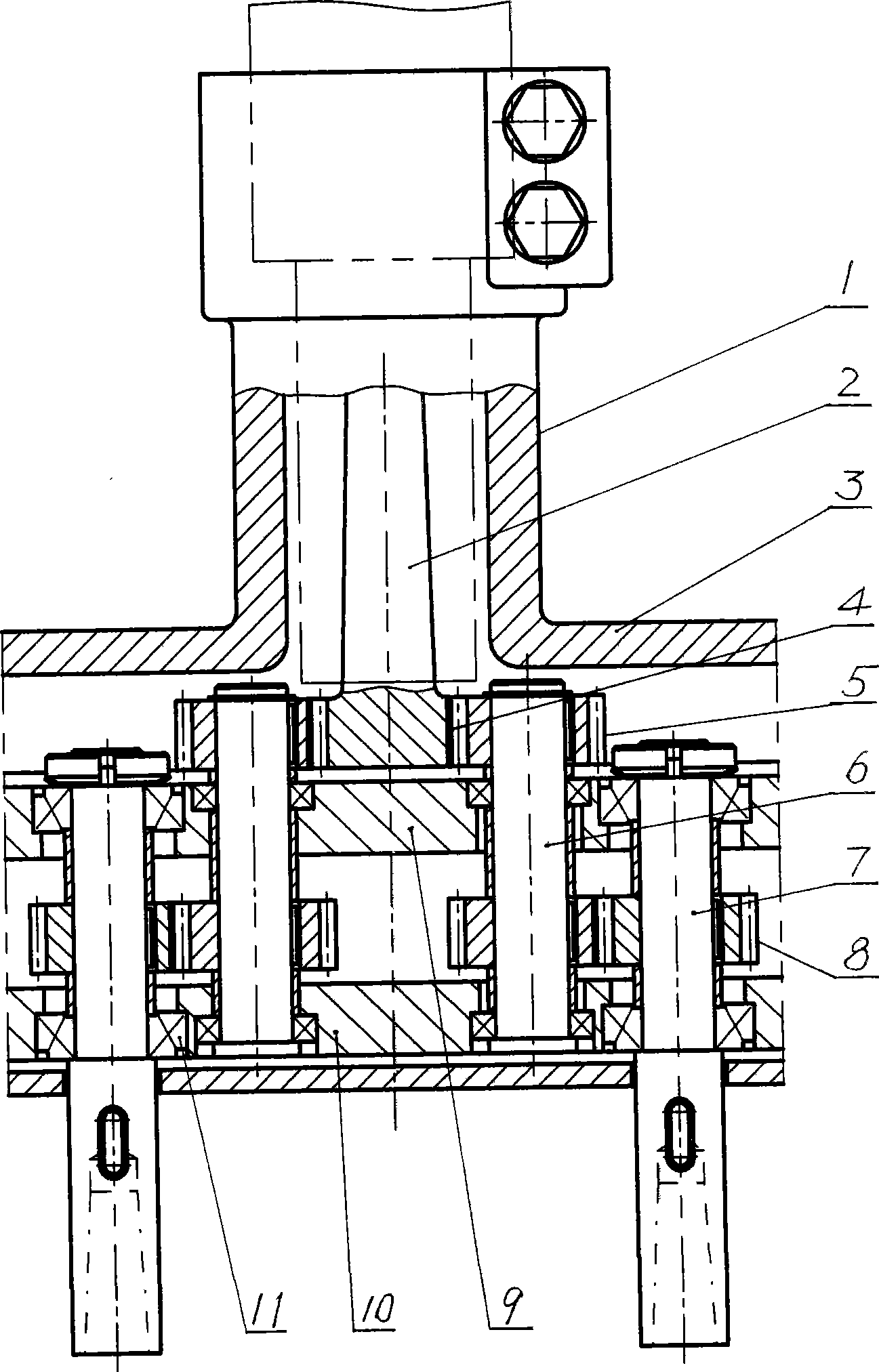

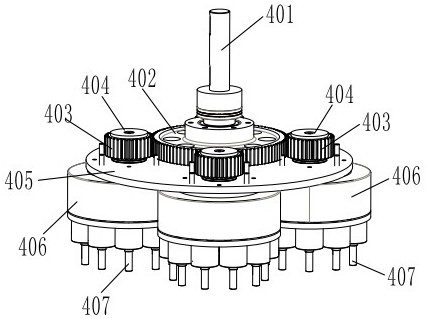

Double-hole processing device for upright drill press

InactiveCN101439418ARealize one clampingReduce labor intensityBoring/drilling componentsBoring/drilling machinesTransmitted powerGear wheel

A double-hole processing device used for a vertical drill press, wherein, a connecting sleeve is arranged at the top of a box-typed connector; the internal chamber is provided with a driving shaft, intermediate shafts and knife tool installing shafts which are parallel to each other; gears arranged on the shafts are mutually meshed to transmit power; amounts of the intermediate shafts and the knife tool installing shafts are respectively two and the intermediate shafts and the knife tool installing shafts are arranged on upper and lower fixed planes in the connector, wherein, a bearing is arranged at the connection. When in use, the device is connected with a principal shaft sleeve of a vertical drill press by the connecting sleeve and the driving shaft cooperates with the principal shaft taper hole of the drill press, thereby realizing one-time clamping of the work piece to process two holes synchronously; therefore, the invention greatly reduces labour intensity and improves productivity effect. The device is especially applicable to mass production.

Owner:YANGDONG CO LTD

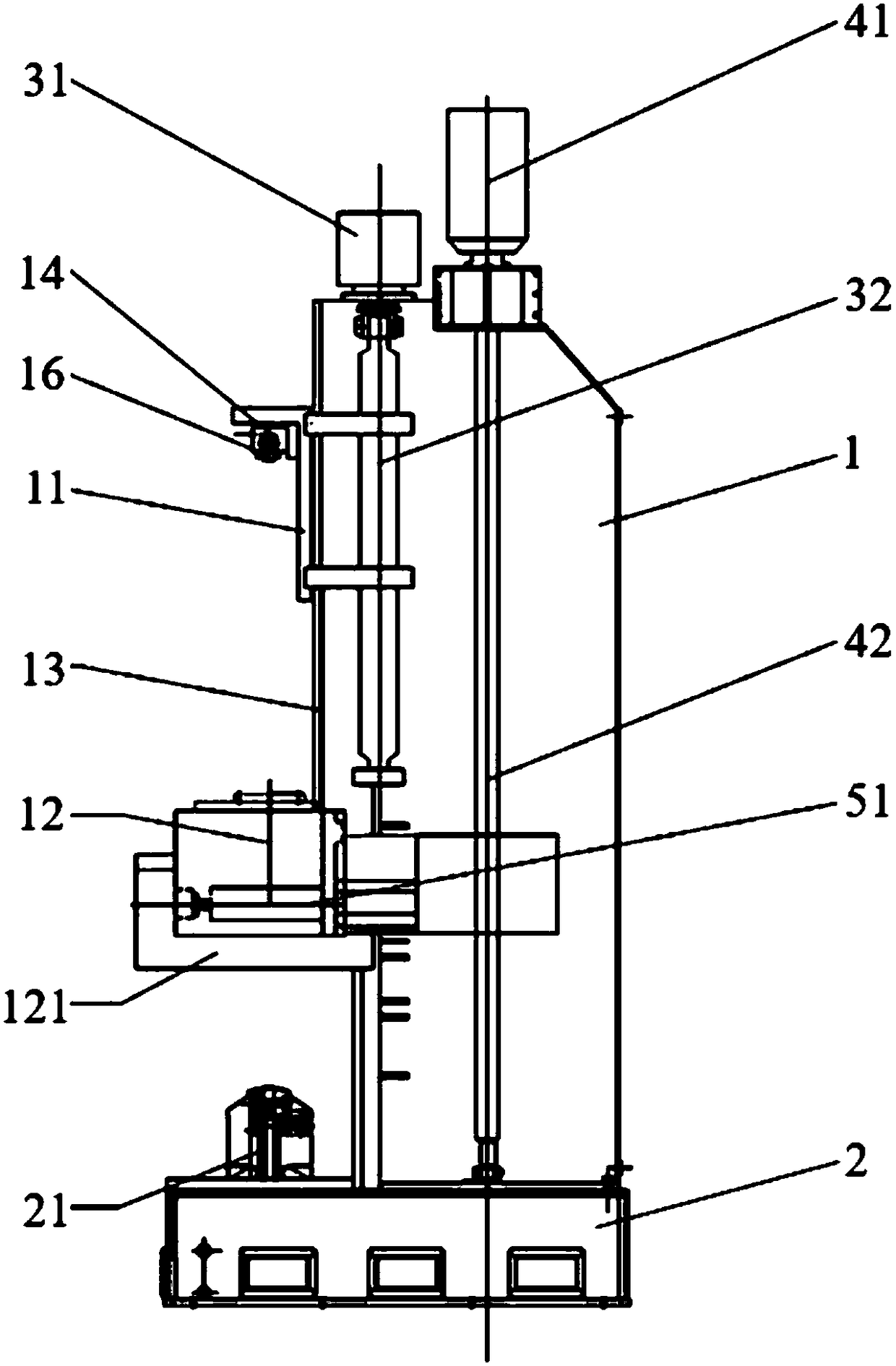

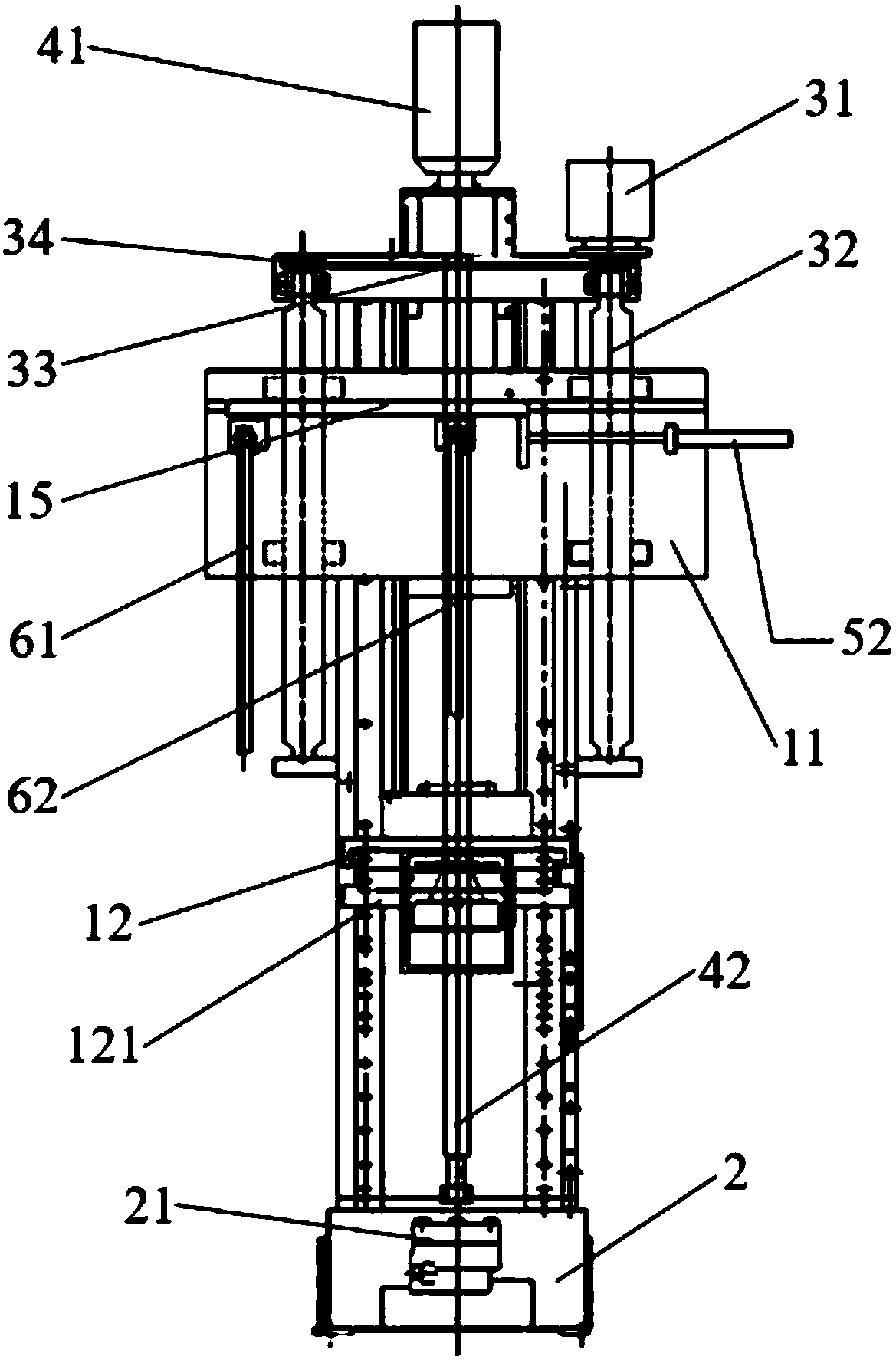

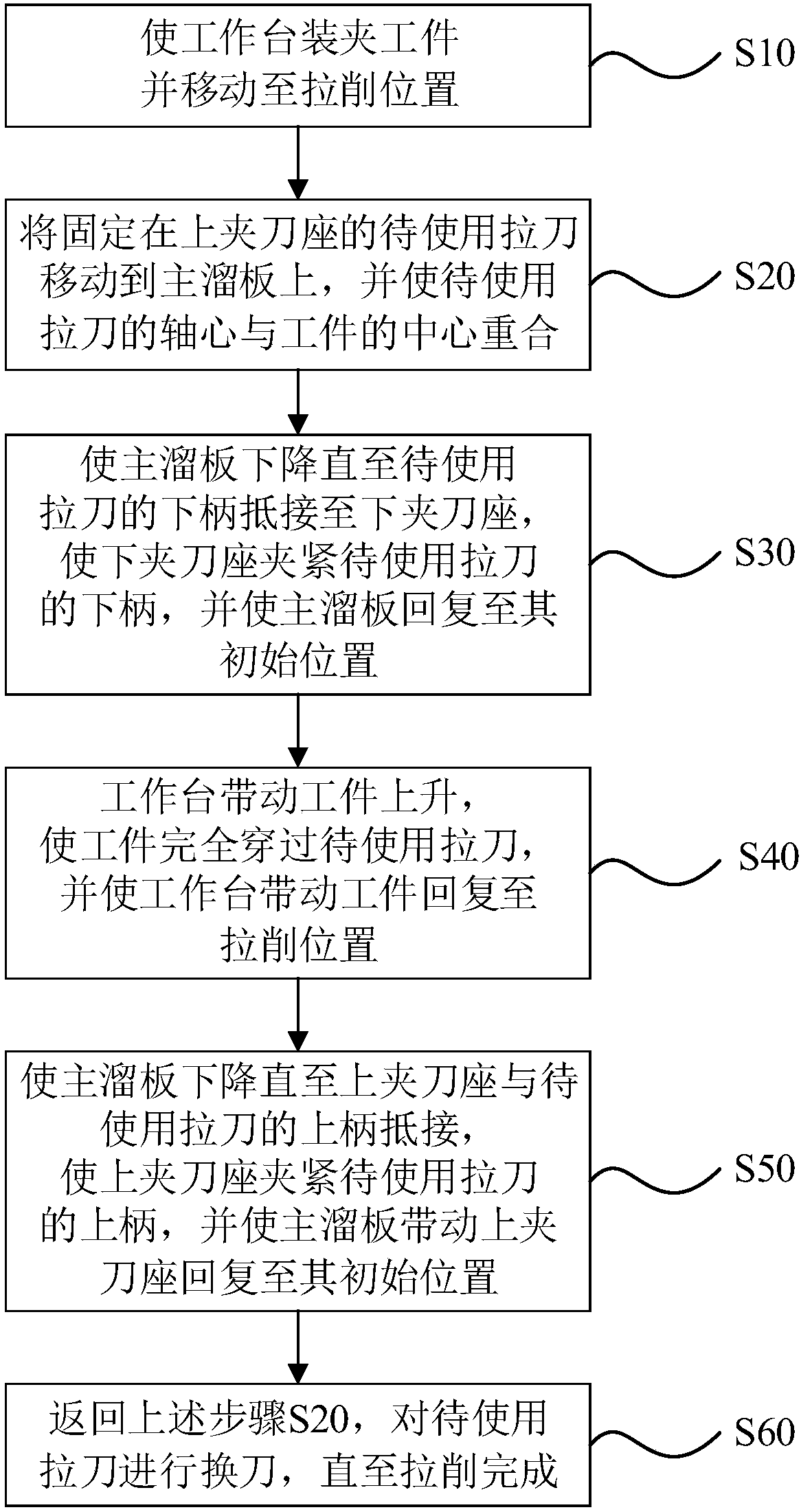

Device for broaching spline and using method thereof

PendingCN108406006ARealize one clampingRealize the beneficial effect of one clampingGear-cutting machinesGear teethEngineeringMechanical engineering

The invention belongs to the technical field of broaching machines and discloses a device for broaching a spline and a using method thereof. The device for broaching the spline comprises a machine body and a base. The machine body is provided with a main slide carriage, a workbench and a tool feeding device. The main slide carriage and the workbench both can move up and down along the machine body. The workbench can clamp a workpiece. The tool feeding device is provided with at least two broaching tools and can drive any broaching tool to be connected to the main slide carriage in a sliding manner. The base is located on the bottom of the machine body and provided with a lower tool clamping base for clamping the broaching tools. According to the device for broaching the spline, the tool feeding device is used for driving any broaching tool to be connected to the main slide carriage in a sliding manner, the main slide carriage descends to the lower tool clamping base along the machine body, and so that the broaching work of the broaching tool on the workpiece is completed; and after broaching, the tool feeding device changes the tool to repeat the operation, and therefore the devicefor broaching the spline can achieve the one-time clamping beneficial effect without repeatedly mounting or demounting the workpiece.

Owner:SHANTUI CONSTR MASCH CO LTD

Aircraft engine key part numerical control broaching center and broaching method thereof

ActiveCN110026605ARealize one clampingReduce tool change timePositioning apparatusBroaching machinesNumerical controlEngineering

The invention discloses an aircraft engine key part numerical control broaching center and a broaching method thereof. A numerical control milling or broaching machining mode and device are currentlyand basically adopted for machining aircraft engine key parts with complicated shapes, broaching has the advantage of high efficiency, but an existing broaching machine lacks an automatic tool changing function. The aircraft engine key part numerical control broaching center comprises a broaching machine body, a tool magazine and a workbench, wherein the broaching machine body comprises a broaching machine driving assembly, a machine bed, a broaching machine guide rail and a broach clamping assembly, the tool magazine comprises a tool magazine seat, a tool magazine two-axis driving assembly, amechanical arm operating table, a rotating mechanical arm, a tool loosening shifting pin, an end-portion rotating tool rest, a broach clamping assembly, a middle rotating tool rest, a rotating shaft,a second bearing seat, a second bearing and a tool rest driving assembly, the broach clamping assembly comprises a swing rod spring, a swing rod and a V-shaped pressing block. According to the aircraft engine key part numerical control broaching center and the broaching method thereof, automatic tool changing of the broaching machine is realized, so that the machining efficiency of the aircraft engine key parts is greatly improved.

Owner:HANGZHOU DIANZI UNIV

Rotatable workbench for machining

InactiveCN112025368ASmooth rotationEasy to liftWork clamping meansLarge fixed membersElectric machineryMachining

The invention provides a rotatable workbench for machining, and relates to the technical field of machining equipment. The rotatable workbench for machining comprises a base, and a rotating plate is fixedly connected to the inner part of the base. A gear ring is arranged on the lower surface of the rotating plate, and a telescopic rod is fixedly connected to the upper surface of the rotating plate. A a workbench body is fixedly connected to the end, far away from the rotating plate, of the telescopic rod. A second air cylinder is fixedly connected to the upper surface of the workbench, and a second connecting rod is fixedly connected to the output end of the second air cylinder. A clamping block is fixedly connected to the end, far away from the second air cylinder, of the second connecting rod. By the arrangement of a motor and a first air cylinder, the workbench can be rotated, lifted and lowered conveniently, one-time clamping is achieved, multiple times of machining can be conducted, the tedious steps of multiple times of clamping are avoided, and the machining efficiency is high. Meanwhile, positioning deviation caused by multiple times of clamping is avoided, and the machining quality is high.

Owner:泉州台商投资区双霞机械设计服务中心

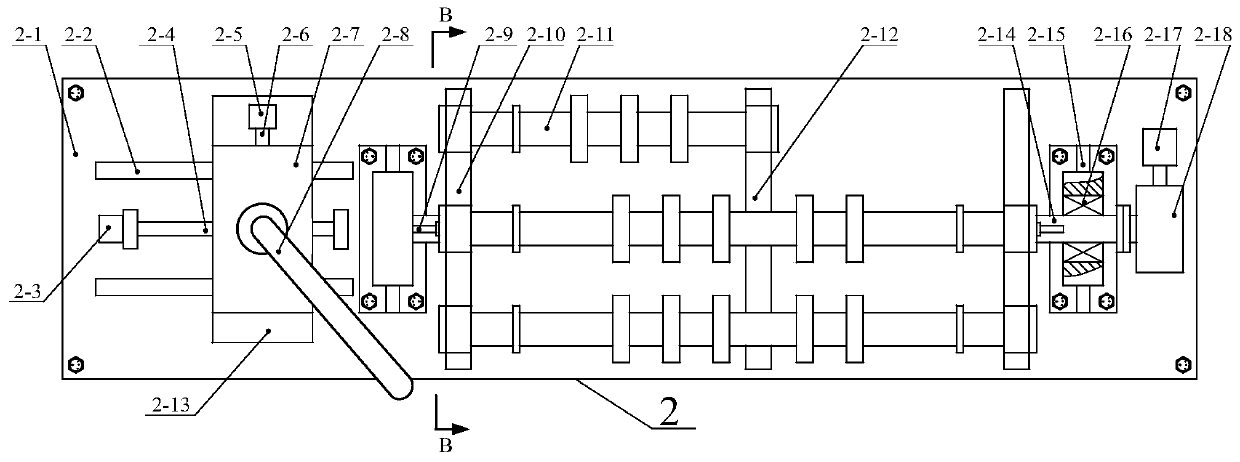

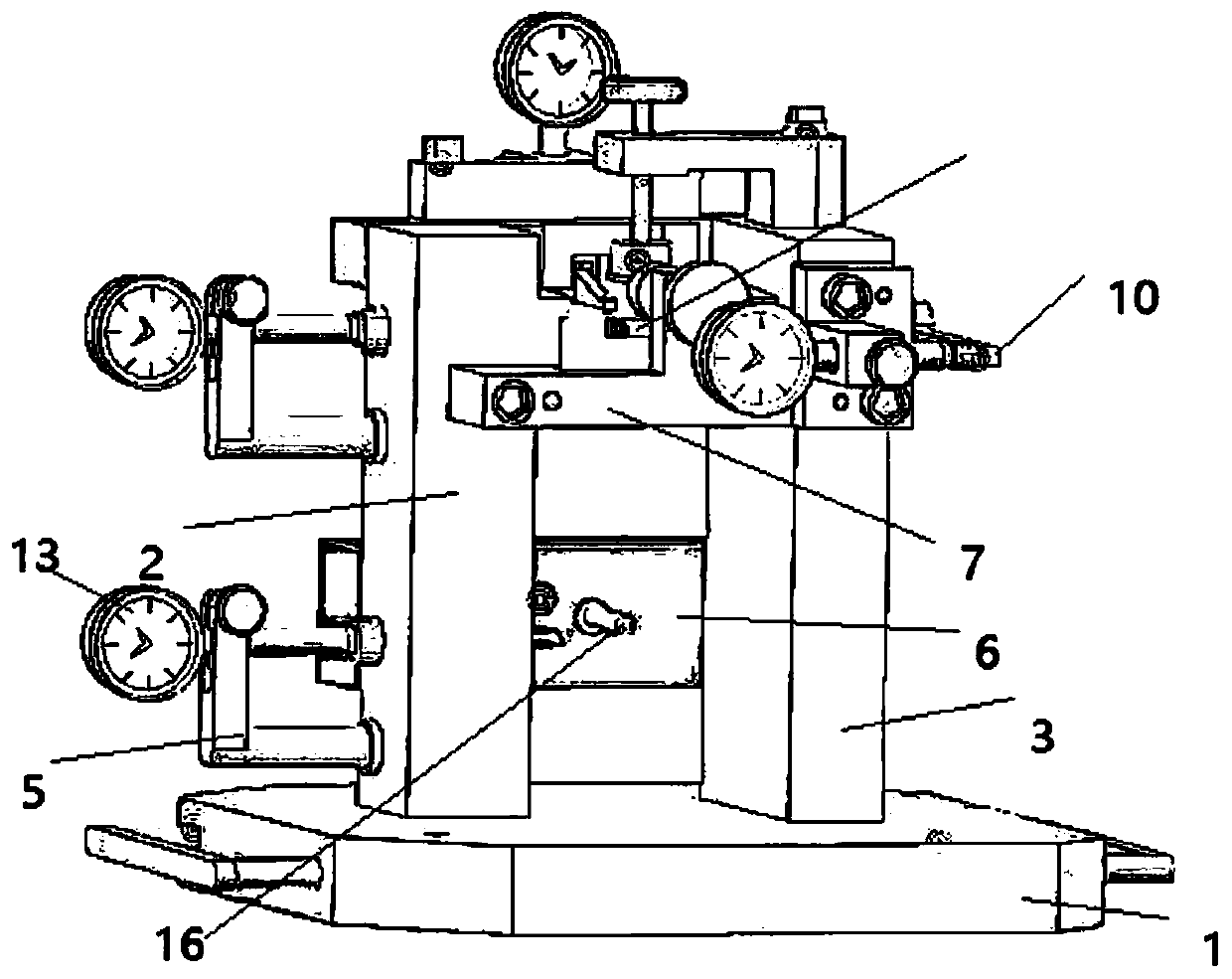

Measuring tool for detecting engine blades

The invention discloses a measuring tool for detecting engine blades. The measuring tool comprises a base, a first positioning support pillar, a second positioning support pillar, a first detection module, a second detection module and a compressing module, wherein the first positioning support pillar and the second positioning support pillar are vertically fixed to the upper surface of the base respectively; the first detection module is arranged at the lower parts of the first positioning support pillar and the second positioning support pillar; the second detection module is arranged at the upper parts of the first positioning support pillar and the second positioning support pillar; the compressing module is arranged at the upper part of the second positioning support pillar; and the compressing module is used for compressing the blades. According to the measuring tool, by setting the first detection module, the second detection module and the compressing module, one-time clamping is realized for detected components, multiple parts are measured simultaneously, the components can be detected in the working procedure of processing, and the dimensions of the components also can be detected in the working procedure of final inspection.

Owner:AECC AVIATION POWER CO LTD

Gantry type five-axis linkage optical glass milling and grinding machine

InactiveCN105397919AAvoid influenceGuaranteed uptimeGrinding carriagesOptical surface grinding machinesEngineeringOptical glass

The invention relates to the field of optical glass milling and grinding equipment, in particular to a gantry type five-axis linkage optical glass milling and grinding machine which comprises a machine body, stand columns, a crossbeam, a rotary workbench, a machine body base and a workbench base. The first supporting column is connected with a first ram through an X-axis feeding mechanism, and the second supporting column is connected with a second ram through an X-axis feeding mechanism. A third ram is perpendicularly arranged on the crossbeam. The third ram is connected with the crossbeam through a Y-axis feeding mechanism. The Y-axis feeding mechanism is provided with a Y-direction sliding seat. The third ram is connected with the Y-direction sliding seat through a Z-axis feeding mechanism. A swinging head and an A-axis feeding mechanism for controlling the swinging head to swing are mounted on the third ram. A tool disc is mounted on the swinging head. The rotary workbench is provided with a C-axis feeding mechanism. The machine body is of a gantry type structure, the structure is simple, maintaining and debugging are convenient, and rigidity and reliability are high; one-time clamping of a workpiece can be achieved, the machine has multiple purposes, and the machining quality and production efficiency of the workpiece are improved.

Owner:芜湖戎征达伺服驱动技术有限公司

Multi-station vertical rotary abrasive flow polishing device and working method thereof

ActiveCN112497043ARealize the whole process of polishingSolve the problem of uneven polishing qualityEdge grinding machinesGrinding carriagesPolishingElectric machine

The invention discloses a multi-station vertical rotary abrasive flow polishing device and a working method thereof, and belongs to the technical field of machining. According to the multi-station vertical rotary abrasive flow polishing device, a plurality of planetary rotary discs are evenly distributed on a rotary disc assembly in the annular direction to correspond to stations of loading, unloading, rough polishing, fine polishing and the like, and a polishing motor drives a workpiece installed below the planetary rotary discs and a polishing medium evenly mixed in a charging basket to rotate relatively to achieve polishing of the workpiece, after certain procedure is finished, the rotary disc assembly drives the workpiece to enter the polishing of the next procedure, so that the whole-process polishing of the workpiece is circularly realized. A planetary rotary disc mechanism is matched with a charging basket assembly internally provided with a fixed flow guide mechanism, so that rotation and revolution of the workpiece are achieved, and the speed required by polishing is achieved; and the polishing medium rotates and overturns up and down along with the charging basket, is uniformly mixed and is prevented from settling and layering. The multi-station vertical rotary abrasive flow polishing device is provided with a plurality of stations, one-time clamping of the workpieceis achieved, multi-station and multi-procedure polishing is conducted at the same time, the polishing process is greatly simplified, and then the overall polishing efficiency is improved.

Owner:DALIAN UNIV OF TECH +1

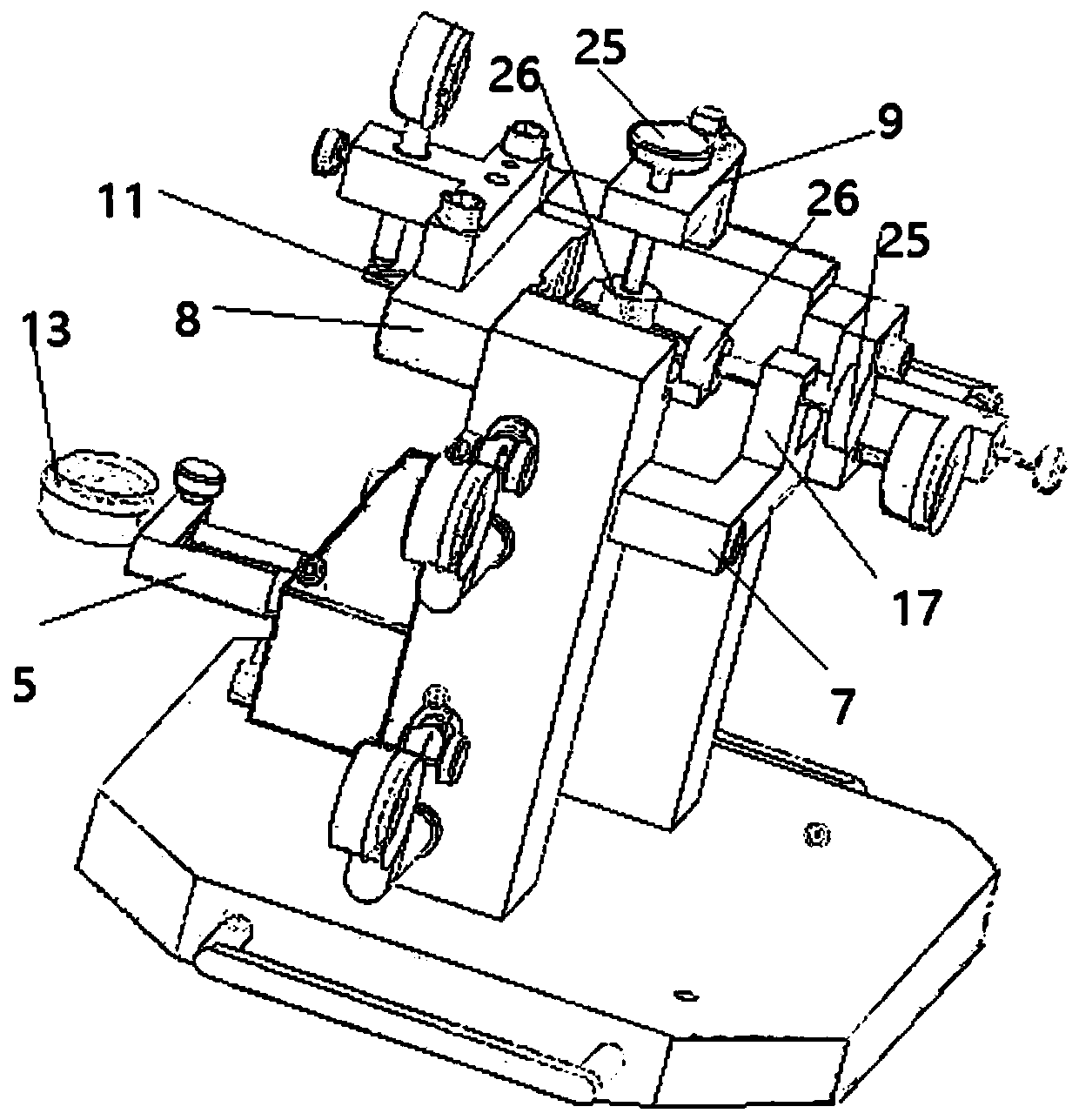

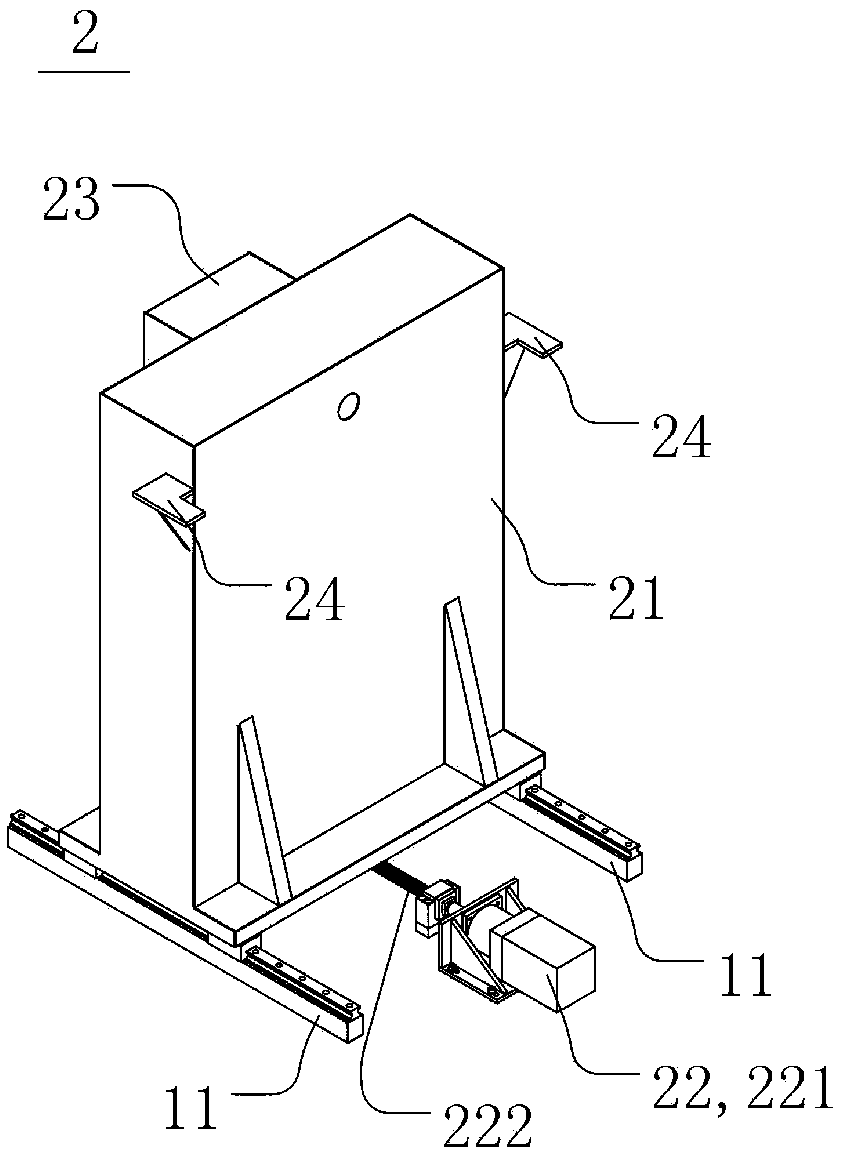

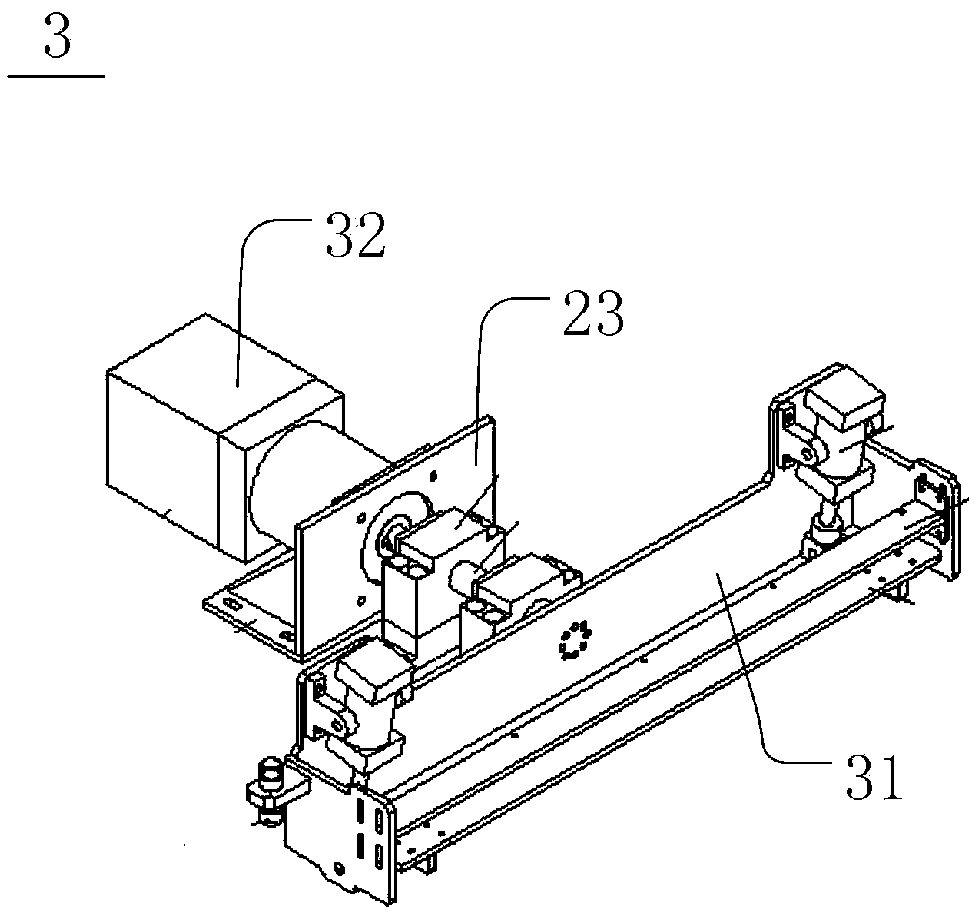

Positioner

PendingCN109128660ARealize one clampingHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringIndustrial engineering

The invention discloses a positioner which comprises a base, two supporting mechanisms and a clamping mechanism, wherein the two supporting mechanisms are arranged on the base in a distance adjustablemanner; and the clamping mechanism is arranged on the supporting mechanisms, is used for clamping a workpiece, and can drive the workpiece to rotate. According to the positioner provided by the invention, the workpiece is clamped by the clamping mechanism, the clamping mechanism can rotate to drive the workpiece to rotate, so that the welding position is changed, one-time clamping of the workpiece can be realized to weld multiple parts, the workpiece processing automation degree is higher, and the operation of personnel is reduced.

Owner:SHIJIAZHUANG ZHONGBO AUTOMOBILE CO LTD +1

Ultrahard-material special-shaped component tensioning positioning tool assembly and milling method

PendingCN111805186AEfficient processingChanging clamping elastic deformationPositioning apparatusMetal-working holdersSuperhard materialMilling cutter

The invention discloses an ultrahard-material special-shaped component tensioning positioning tool assembly and milling method. The method comprises the following steps of discharging materials; rough-machining a special-shaped component; making a reserved clamping process step on the reference surface of the component; making process threaded holes in the reserved clamping process step for beingconnected with tools for tensioning positioning during positioning clamping; machining a groove at the bottom of the process step; performing quenching treatment; making the process threaded holes inthe process step surface; performing semi-finish machining by taking the process plane as a reference plane, and performing semi-finish machining on the step surface of the semi-finish milling processby using a milling cutter; performing aging treatment; finding a reference plane and finish-machining a reference hole with a margin to obtain a final reference hole; using a first tensioning tool component to complete semi-finish milling of each profile; performing finish machining, wherein a second tensioning positioning tool component is used for tensioning and positioning, and performing bottom-tooth micro-cutting machining by adopting a fine milling cutter; and removing the process step. The method enables efficient machining of ultrahard material special-shaped components.

Owner:CHANGZHI QINGHUA MACHINERY FACTORY

High-speed aviation rotor blade tip grinding machine

PendingCN113245971ASimple structureReduce complexityEdge grinding machinesGrinding carriagesAviationStructural engineering

The invention belongs to the technical field of machining, and particularly relates to a high-speed aviation rotor blade tip grinding machine. The machine comprises a horizontally-arranged base, wherein an X-axis guide rail is arranged on the base, an X-axis moving frame is connected to the X-axis guide rail in a sliding manner, and a first driving mechanism for driving the X-axis moving frame to move is arranged on the base. A main shaft clamping mechanism and a grinding wheel dresser are arranged on the X-axis moving frame. An optical measuring mechanism and a multi-station grinding wheel library are arranged on the two sides of the X-axis moving frame. A portal frame is erected above the X-axis guide rail and comprises stand columns and a cross beam, a Y-axis guide rail horizontally arranged in the longitudinal direction is arranged on the cross beam of the portal frame, a Y-axis moving frame is connected to the Y-axis guide rail in a sliding manner, and a second driving mechanism for driving the Y-axis moving frame to move is arranged on the cross beam. A Z-axis guide rail arranged in the vertical direction is arranged on the Y-axis moving frame, a lifting frame is connected to the Z-axis guide rail in a sliding manner, a third driving mechanism for driving the lifting frame to move is arranged on the Y-axis moving frame, and a grinding wheel mechanism is arranged at the bottom of the lifting frame. The device is simple in structure and high in reliability.

Owner:台州中驰智谷科技有限公司

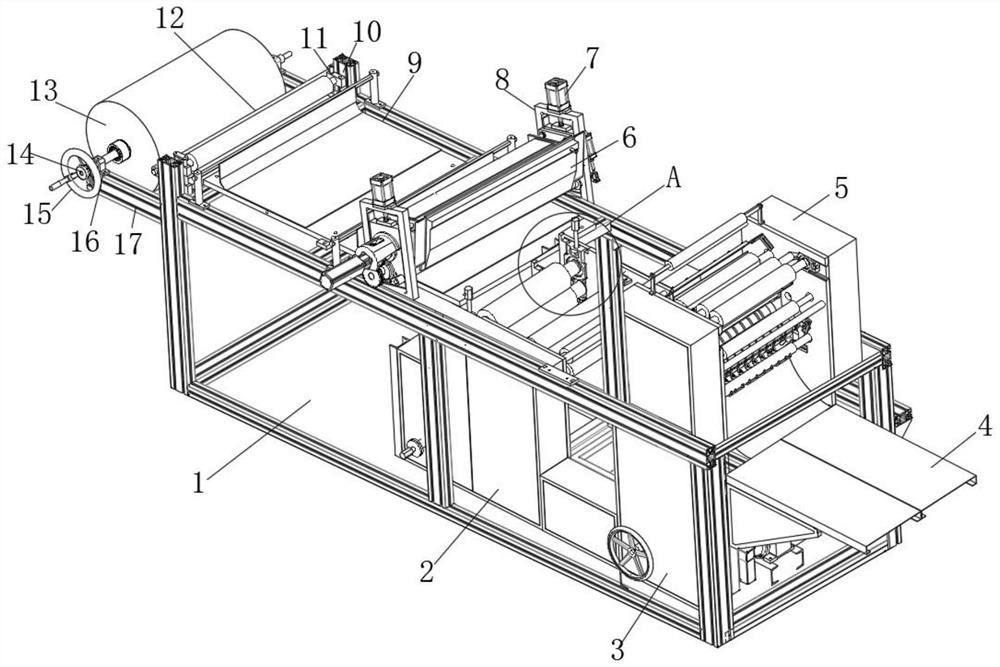

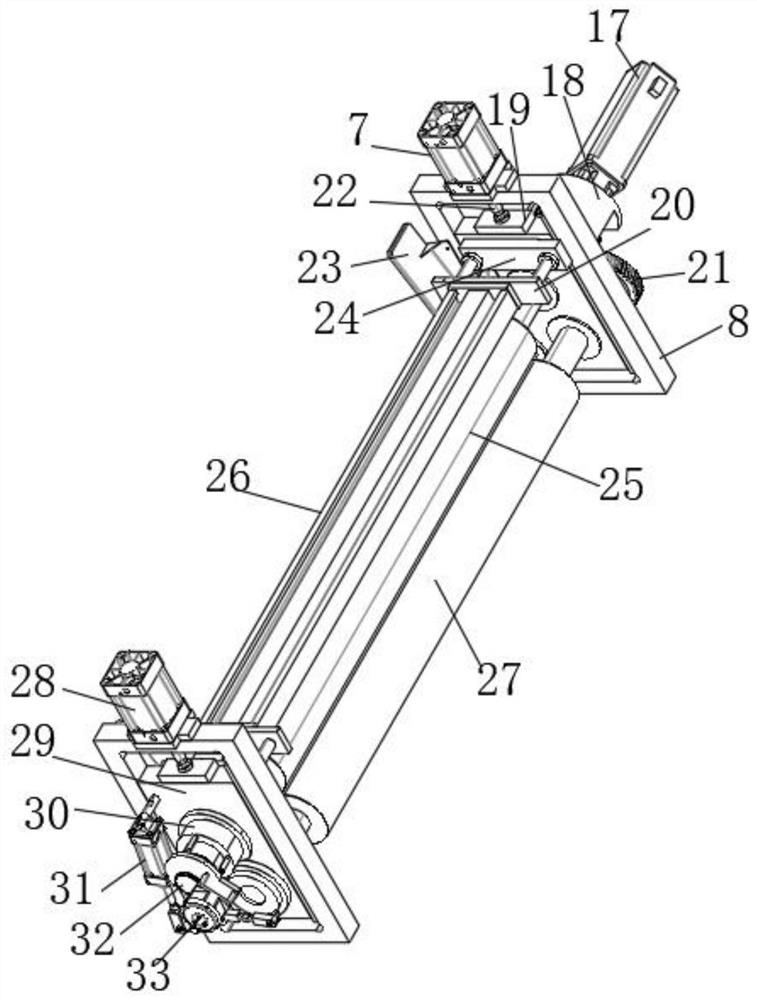

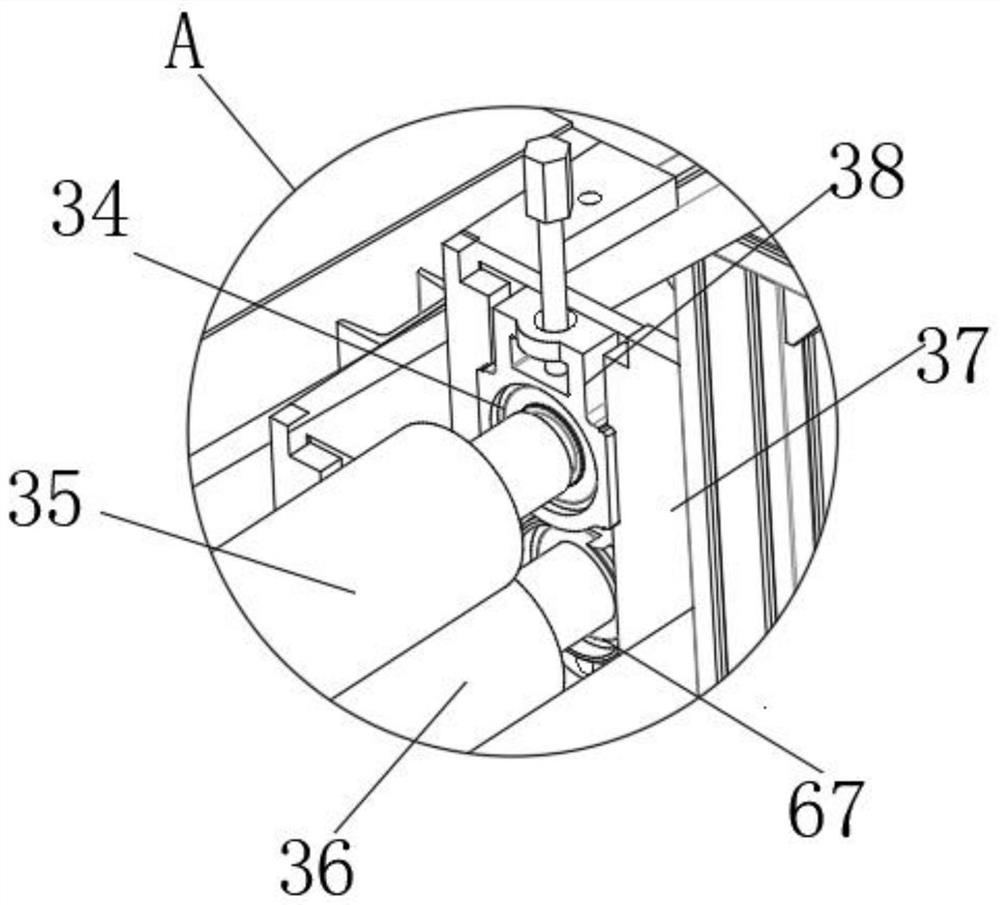

Multifunctional printing device based on garment processing

InactiveCN112644154AAchieve clampingSimple structureRotary pressesOther printing apparatusTextile printerGear wheel

The invention discloses a multifunctional printing device based on garment processing. The multifunctional printing device comprises a frame assembly, a first installation box and a second installation box are separately installed in a frame of the frame assembly, the first installation box is located on the left side of the second installation box, and a slicing base is installed on one side of the second installation box. According to the multifunctional printing device based on the garment processing, a positioning roller is adjusted, a displacement roller is driven to rotate after a supporting plate rotates, meanwhile, a cylinder connected with the driving end of the supporting plate is used for driving a small gear disc to rotate, and a first gear meshed with the outer wall of the small gear disc can drive the positioning roller to rotate; an electric telescopic rod is controlled to pull one end of the positioning roller by a motor, and the positioning roller moves towards the displacement roller, so that a contact area of the displacement roller and the positioning roller is reduced.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

Special clamp for multi-surface milling and boring of large parts

PendingCN113427299AReasonable designEasy to operatePositioning apparatusMetal-working holdersJackscrewScrew thread

The invention discloses a special clamp for multi-surface milling and boring of large parts, and belongs to the technical field of machining of artillery parts. The clamp comprises a clamp body, lifting bolts, a compression screw, a movable handle compression screw, a star-shaped pressing plate, positioning plates A, a positioning supporting column and a positioning plate B; supporting bodies are fixedly connected to the left side, the front side and the right side of the top of the clamp body, the compression screw is in threaded connection with the interior of the supporting body on the left side, and the positioning supporting column is connected in the supporting body on the right side; a movable jackscrew seat is arranged in a machine tool groove of a machine tool workbench and is in threaded connection with the movable handle compression screw; a long screw in the vertical direction is fixedly connected to the center of the upper plane of the clamp body in a threaded mode, and the positioning plates A are mounted on the front side and the rear side of the long screw and on the upper plane of the clamp body; the lifting bolts are in threaded connection to the two sides of the clamp body, and the positioning plate B is connected to the back of the supporting body on the front side of the upper plane of the clamp body. Grooves and holes in the three surfaces of a workpiece can be machined through one-time clamping.

Owner:QIQIHAR NORTH MACHINERY CORP

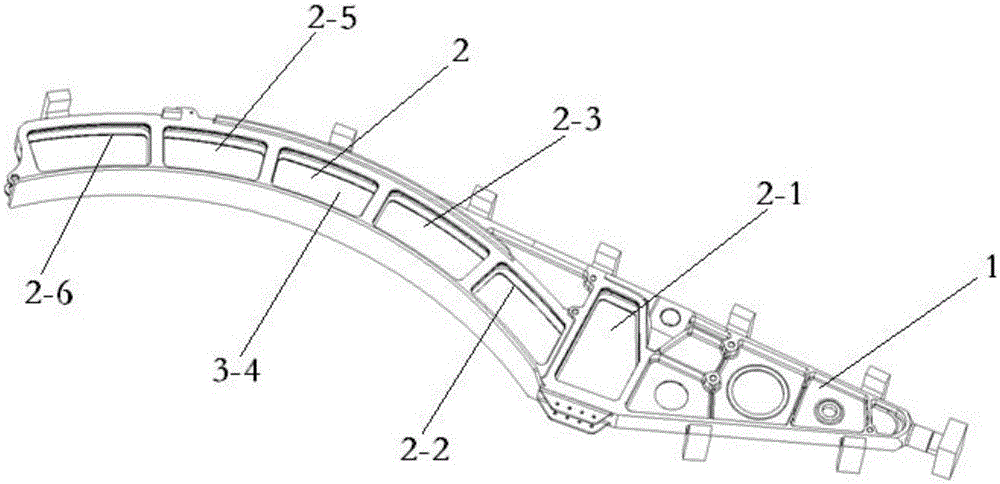

Welding jig for conducting vacuum electron beam welding on airplane flap sliding rail structural part

ActiveCN104999208ARealize one clampingAvoid welding deformationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

Disclosed is a welding jig for conducting vacuum electron beam welding on an airplane flap sliding rail structural part. The structural part comprises a sliding rail body with multiple cavities and multiple webs corresponding to the cavities and needing to be welded. A body of the jig is of a flat-board-shaped rigid structure and is provided with multiple locating connecting holes, locating blocks and multiple windows, wherein the locating connecting holes and the locating blocks correspond to the appearance of the sliding rail body and the windows correspond to the cavities of the sliding rail body. The boundary of each window is larger than that of the corresponding cavity of the sliding rail body. The middle portions of the two ends of the body are each provided with a shaft-shaped connecting head. Two stand bars are located at the two ends of the body. Lug grooves are arranged at the top ends of the stand bars. The connecting heads are supported in the lug grooves in the top ends of the stand bars at the two ends respectively and fixed through plug pins.

Owner:XI'AN AIRCRAFT INTERNATIONAL

Horizontal type polishing device for processing of automobile accessories

PendingCN108705415ARealize one clampingImprove processing efficiencyGrinding carriagesGrinding drivesMotor driveGrinding wheel

The invention discloses a horizontal type polishing device for processing of automobile accessories. The horizontal type polishing device for processing of the automobile accessories comprises a pedestal, a first moving base and a second moving base; first guide rails are arranged on the top end face of the pedestal in a front and back symmetrical mode; a first screw rod is arranged between the two first guide rails; a first moving base matched with the first screw rod is arranged on the first screw rod in a sleeving way; a working platform is arranged at the right side end of the first movingbase; two second guide rails are arranged on the right side of the top end face of the pedestal; a second screw rod is arranged between the two second guide rails; a second moving base matched with the second guide rails are arranged on the second screw rod in a sleeving way; the left side end of the second moving base is fixedly connected with an electric telescopic rod; the other end of the electric telescopic rod is fixedly connected with a third motor; a motor shaft of the third motor is fixedly connected with a rotating shaft; the second motor drives the second moving base to move back and forth, so that a grinding wheel can move back and forth; and the grinding wheel moving left and right is fixed through the electric telescopic rod, so that process of multiple end faces during one-time clamping of a workpiece is realized and the processing efficiency is greatly improved.

Owner:杨真

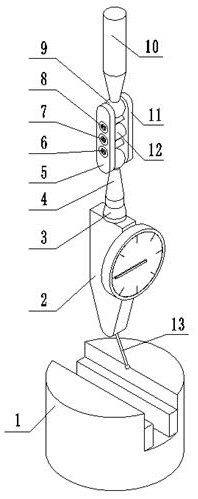

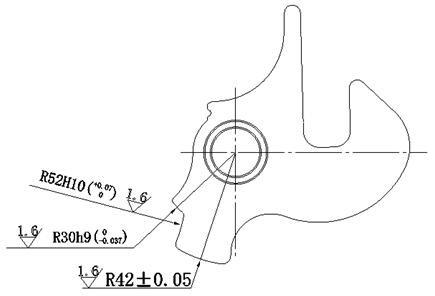

Online measuring method and device for cutter radius compensation value of numerical control milling precision inferior arc

InactiveCN113377068ARealize one clampingHigh accuracy of measurement resultsProgramme controlComputer controlNumerical controlEngineering

The invention discloses an online measuring method and device for a cutter radius compensation value of a numerical control milling precision inferior arc, and the method comprises the steps: placing a standard block with a groove on a workbench, determining an auxiliary circle through a measuring needle in a lever indicator, and enabling the auxiliary circle to be tangent to the midpoint of the inferior arc; determining a corresponding X value and a corresponding Y value according to the origin coordinate value of the inferior arc and the center coordinate value of the auxiliary circle; moving the machine tool workbench to enable a machine tool spindle to reach the center position of the auxiliary circle; then moving a machine tool spindle to enable a measuring needle in the lever indicator to be in contact with the inferior arc, recording the grid degree of the dial plate deviating from the zero position, and calculating the actual radius of the inferior arc through the recorded grid degree; and finally, calculating the actual radius and the theoretical radius of the inferior arc, and calculating a corresponding compensation value according to the machining precision of the inferior arc. The online measuring method and device have the advantages of being simple in structure, convenient to operate and use, capable of improving the machining efficiency and precision, high in practicability and suitable for application and popularization.

Owner:贵州龙飞航空附件有限公司

Multi-angle multi-station drill clamp

The invention discloses a multi-angle multi-station drill clamp. The multi-angle multi-station drill clamp comprises a valve sleeve positioning block for clamping a valve sleeve, wherein the valve sleeve positioning block is a cuboid, and internally provided with a storage cavity; a fastening device is arranged on one side of the storage cavity; through holes which penetrate through the outer wall of the valve sleeve positioning block and are communicated to the storage cavity are formed in the valve sleeve positioning block; and the through holes correspond to drill holes of the valve sleeve in the storage cavity in positions and angles. According to the multi-angle multi-station drill clamp adopting the structure, before the valve sleeve is drilled, the valve sleeve is firstly placed in the storage cavity of the valve sleeve positioning block and fastened through the fastening device; and due to the fact that the through holes in the valve sleeve positioning block correspond to the drill holes of the valve sleeve in the storage cavity in positions and angles, the valve sleeve does not need to be carried out angle measurement, and a drill rod directly extend into the through holes so as to drill the valve sleeve in accurate positions.

Owner:TIANJIN KEDE TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com