Numerical control machining tool and rotary work platform thereof

A technology of CNC machining machine tool and rotary table, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of high precision of shape and position, short processing cycle, high efficiency and high quality processing, which can only be solved. Do linear motion and other problems to achieve good cutting efficiency, ensure positional accuracy, and high cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

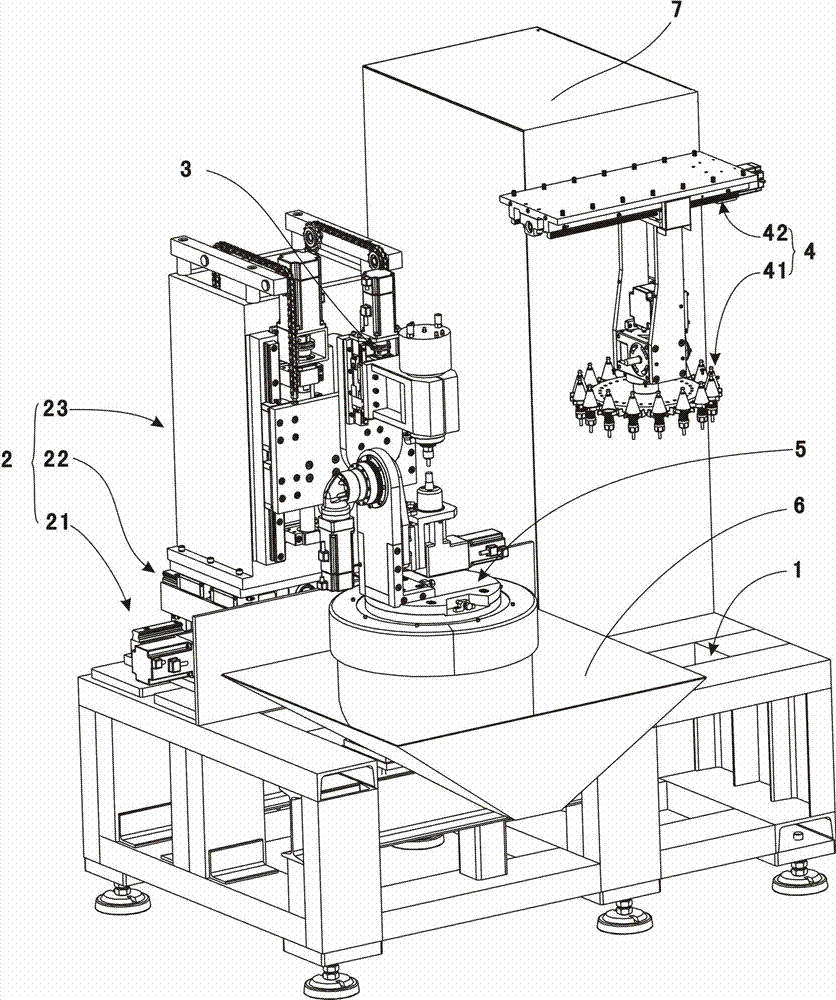

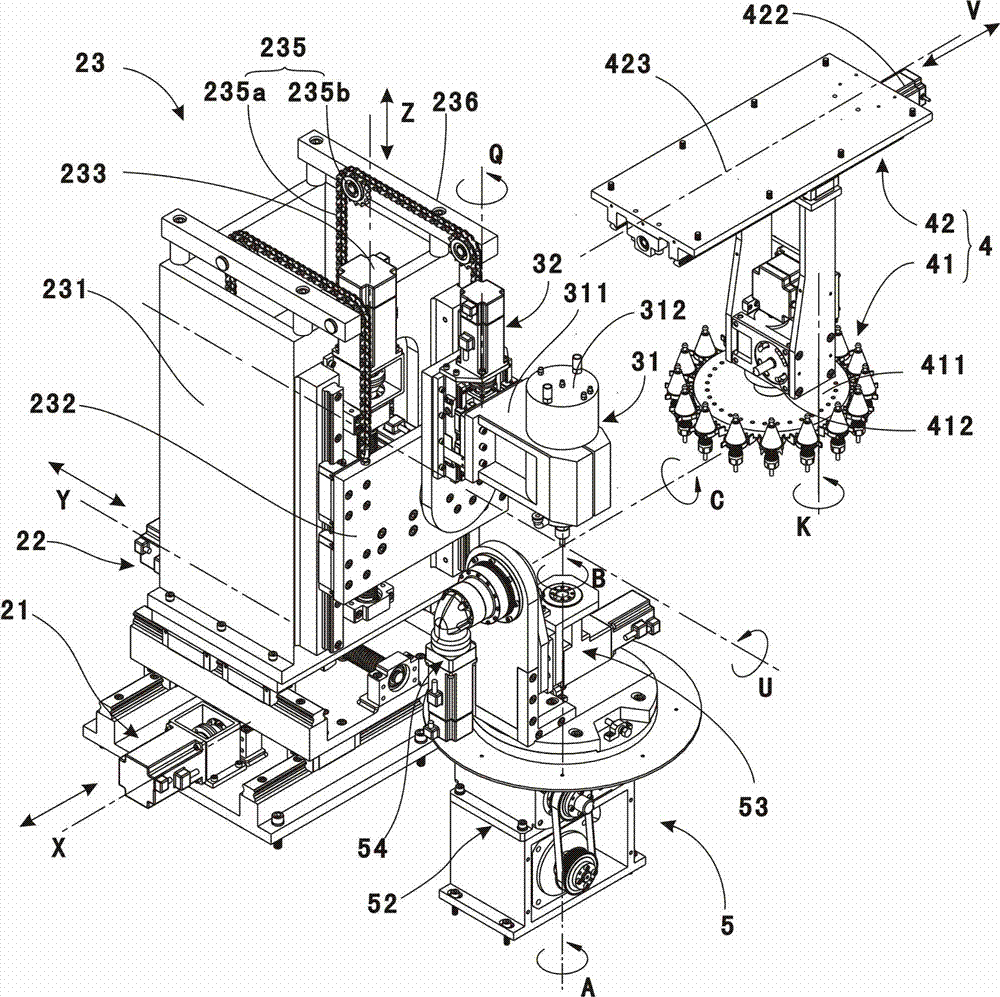

[0032] see figure 1 , a numerically controlled machine tool provided in a preferred embodiment of the present invention, comprising a base 1 , a translation device 2 , a spindle device 3 , a tool magazine device 4 , a rotary table 5 , a chip collecting device 6 , and an electrical control cabinet 7 . The main shaft device 3 is connected to the base 1 through the translation device 2, the rotary table 5, the chip collection device 6, and the electrical control cabinet 7 are all fixed on the base 1, the chip collection device 6 is funnel-shaped, and the rotary table 5 is set in the chip collecting device 6, so as to collect the chips.

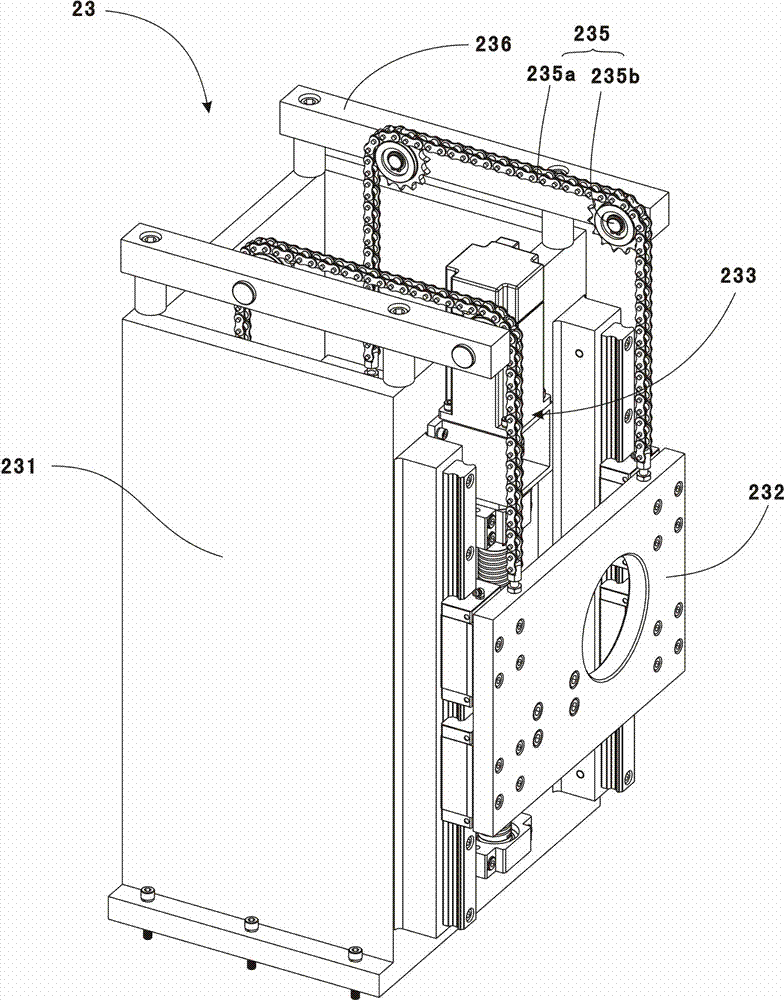

[0033] Such as figure 1 , figure 2As shown, the translation device 2 is used to drive the main shaft device 3 to translate along the mutuall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com