Welding jig for conducting vacuum electron beam welding on airplane flap sliding rail structural part

A technology of vacuum electron beam welding and welding fixture, which is applied in electron beam welding equipment, welding equipment, welding equipment, etc., to reduce the number of clamping times, improve welding quality, and prevent welding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

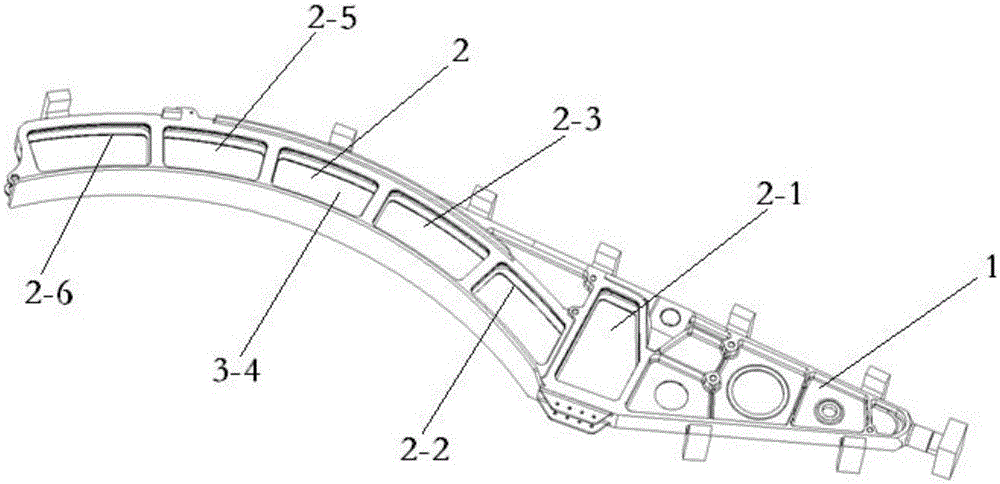

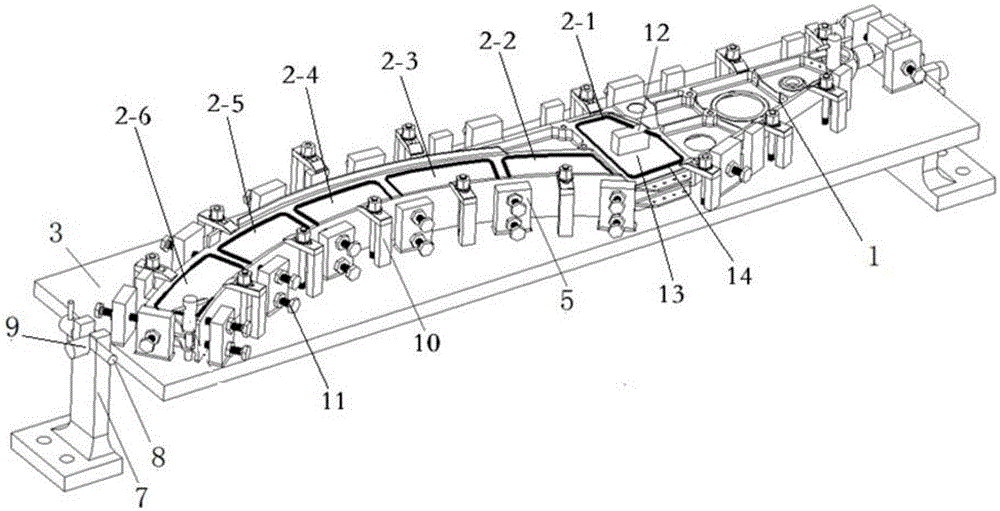

[0014] Referring to the accompanying drawings, the embodiment shows a welding method and welding fixture for an aircraft flap slide rail structure. Aircraft slide rails are mainly composed of cross-section "I"-shaped slideways, solid and hollow webs, connecting shafts and reinforcing ribs, etc., and their materials are ultra-high-strength steels that are difficult to process. The slide rail body of the flap slide rail 1 such as figure 1 As shown, there are six adjacent abdominal cavities 2, the first abdominal cavity 2-1, the second abdominal cavity 2-2, the third abdominal cavity 2-3, the fourth abdominal cavity 2-4, the fifth abdominal cavity 2-5 and the fifth abdominal cavity Six abdominal cavities 2-6, the process requires that thin webs 13 that match the shape of the abdominal cavity need to be welded on both sides of each abdominal cavity.

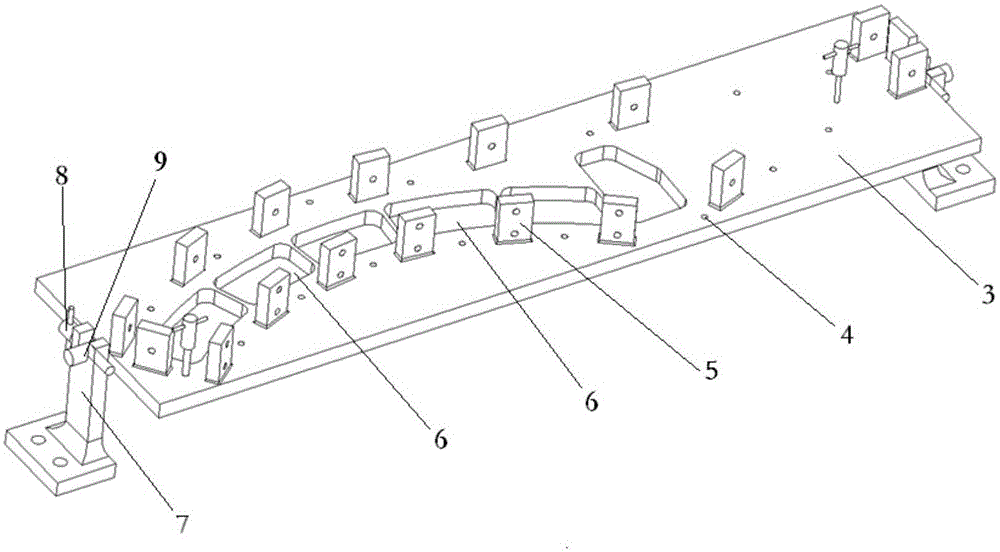

[0015] In order to control the deformation during welding and improve the processing efficiency, this application specially design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com