Special clamp for multi-surface milling and boring of large parts

A technology of large-scale parts and special fixtures, which is applied in the direction of metal processing machinery parts, clamping, manufacturing tools, etc., can solve the problems of complex and cumbersome processing procedures, low production efficiency, affecting production progress and economic benefits, and save auxiliary time , easy operation, small vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

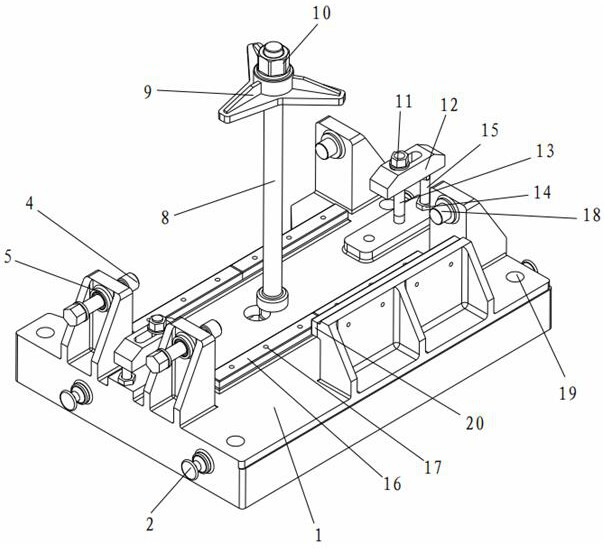

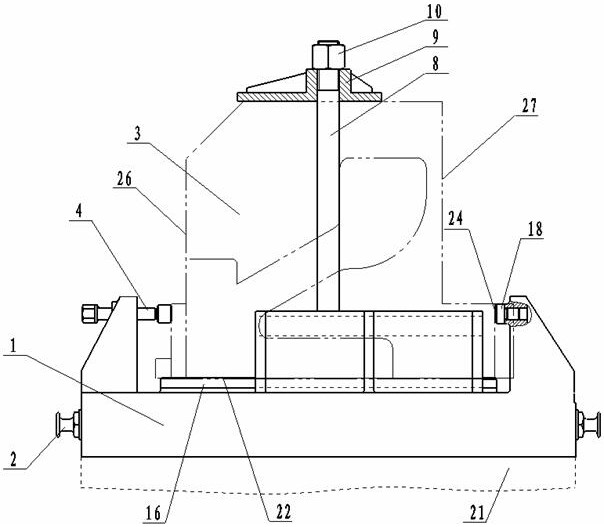

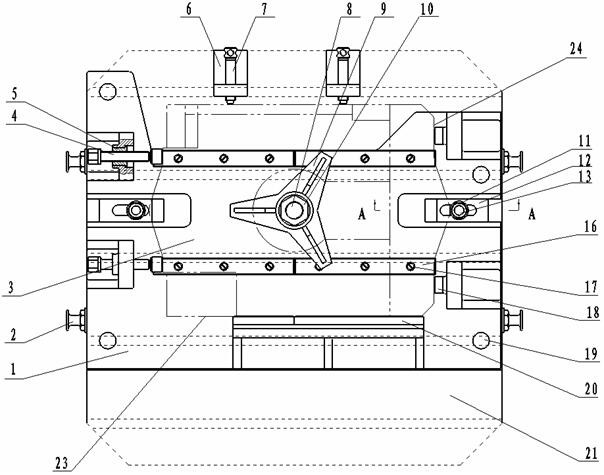

[0031] Such as figure 1 As shown in —12, a special fixture for multi-face milling and boring of large parts, including fixture body 1, lifting bolt 2, compression screw 4, movable handle compression screw 7, star-shaped pressure plate 9, positioning plate A16, positioning pillar 18 and The positioning plate B20, the fixture body 1 is a cast-molded workpiece, the fixture body 1 at the bottom is a skeleton-type cuboid base, and the three side edges on the left side, the front side and the right side of the top are fixedly connected with raised support bodies, Bushings 5 are installed in the two supporting bodies spaced apart on the left side, and a horizontal compression screw 4 is threaded in the bushings 5, and the two supporting bodies spaced apart on the right side are fixedly connected respectively. There is a positioning pillar 18 in the horizontal direction, and the positioning surface of the positioning pillar 18 faces to the left; on the rear side of the fixture body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com