Online measuring method and device for cutter radius compensation value of numerical control milling precision inferior arc

A tool radius and measurement method technology, applied in the field of mechanical processing, can solve problems such as no way to measure machine tools, inconsistent compensation values and measured values, scrapped workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] To further illustrate the concept of the present invention, the following in conjunction with the accompanying drawings of specific embodiments of the present invention will be further described in detail:

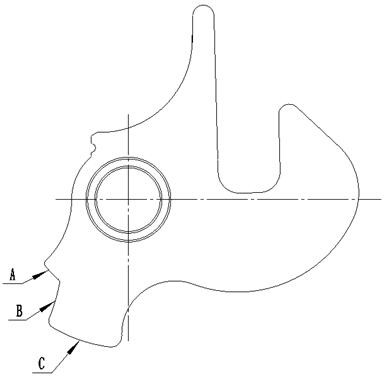

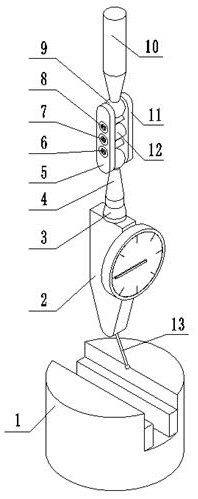

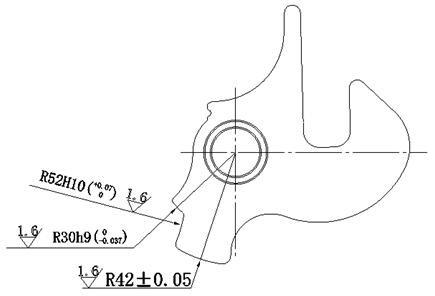

[0024] due to figure 1 Machining accuracy in A, B, C three minor arc involved is relatively high, when the NC machining center, when the program has completed the shape, dimensions do not know how, and are not measured on the machine, can not meet their processing accuracy. Therefore, the design of a standard block in a standard block and open a recess, the width of the groove may vary depending on different cases minor arc, we can design different specifications, to meet the convenience, the groove width of the design of the present application the three sizes, namely 20mm, 12mm and 8mm. Specifications used herein is a groove width of 20mm. The working principle of leverage dial indicator 2, carry the first lever dial indicator is mounted on the machine spindle 2, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Division value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com