Horizontal type polishing device for processing of automobile accessories

An auto parts, horizontal technology, used in grinding drives, metal processing equipment, grinding machines, etc., can solve the problems of low efficiency, low grinding quality, time-consuming and laborious, etc., to improve work efficiency, improve processing efficiency, reduce The effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

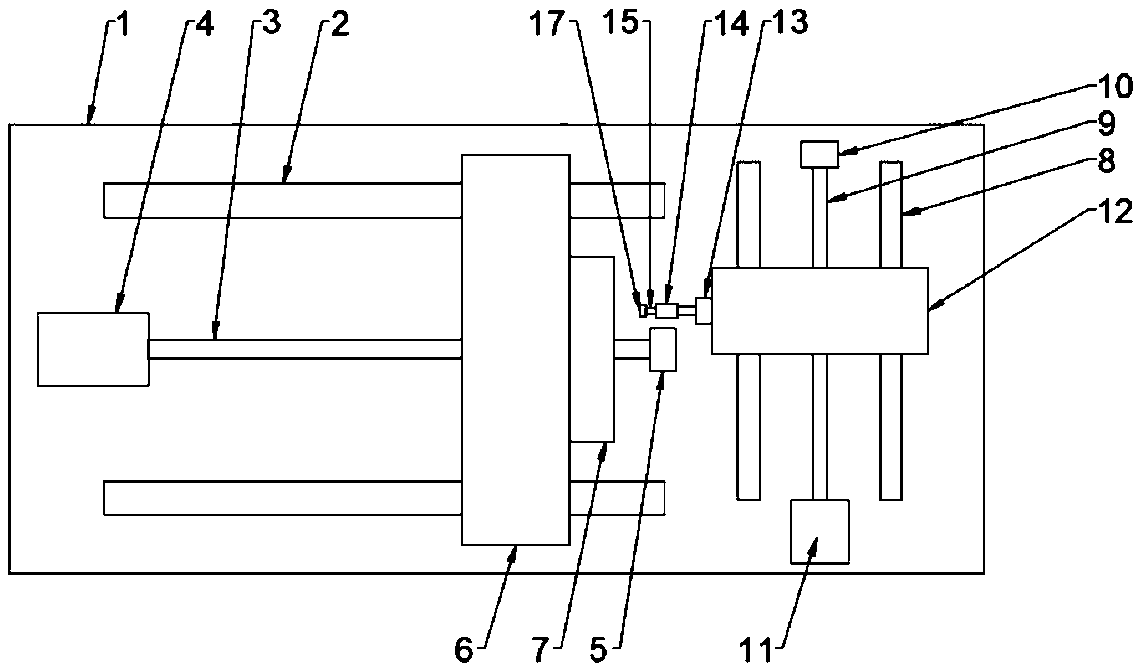

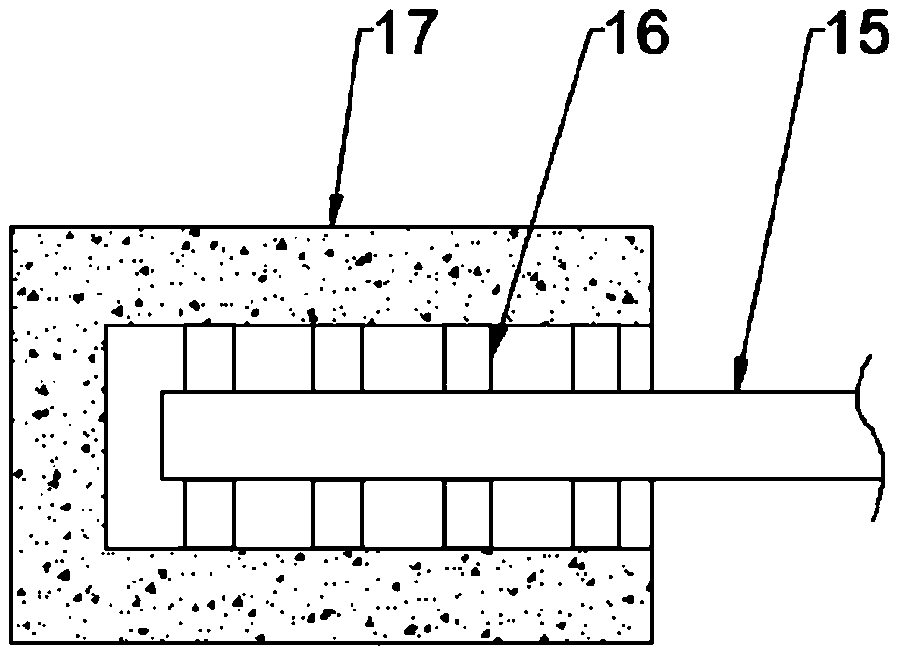

[0020] see Figure 1~2 , a grinding device for horizontal auto parts processing, comprising a base 1, a first moving seat 6 and a second moving seat 12, the top of the base 1 is symmetrically provided with a first guide rail 2, two of the first The guide rail 2 is arranged on the left side of the top surface of the base 1, the first guide rail 2 is a T-shaped guide rail, a first lead screw 3 is arranged between the two first guide rails 2, and a Arranged parallel to each other, one end of the first lead screw 3 is rotatably connected to the base 1 through the first bearing seat 5, and the other end of the first lead screw 3 is fixedly connected to the motor shaft of the first motor 4, and the first motor 4 Fixedly connected to the top of the base 1, the first lead screw 3 is sleeved with a first moving seat 6 matched with the first lead screw 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com