Device for broaching spline and using method thereof

A technology of spline and fine broaching, which is applied to gear tooth manufacturing devices, components with teeth, gear teeth, etc., can solve the problems of large floor space, large machine tool volume, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

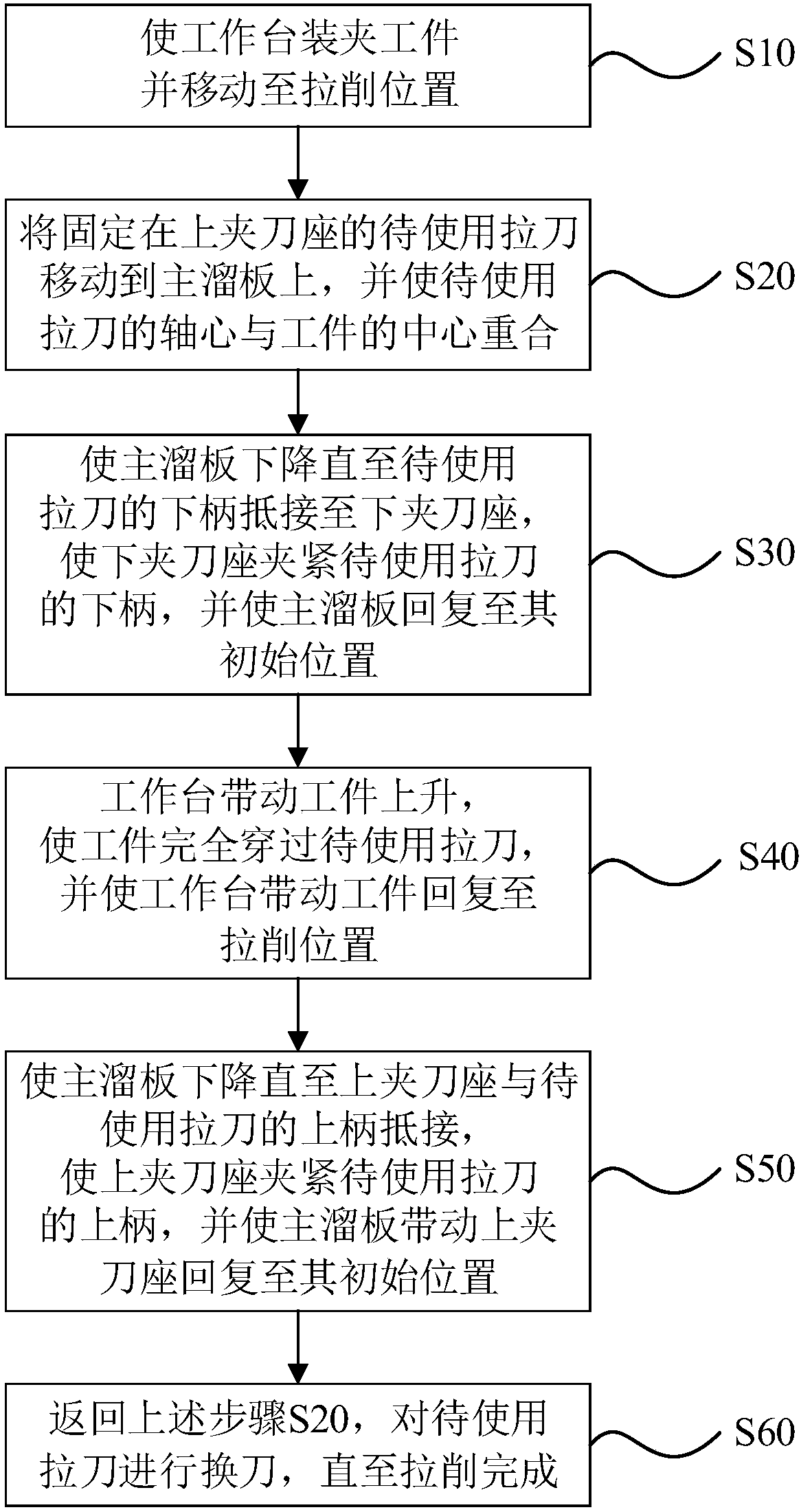

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

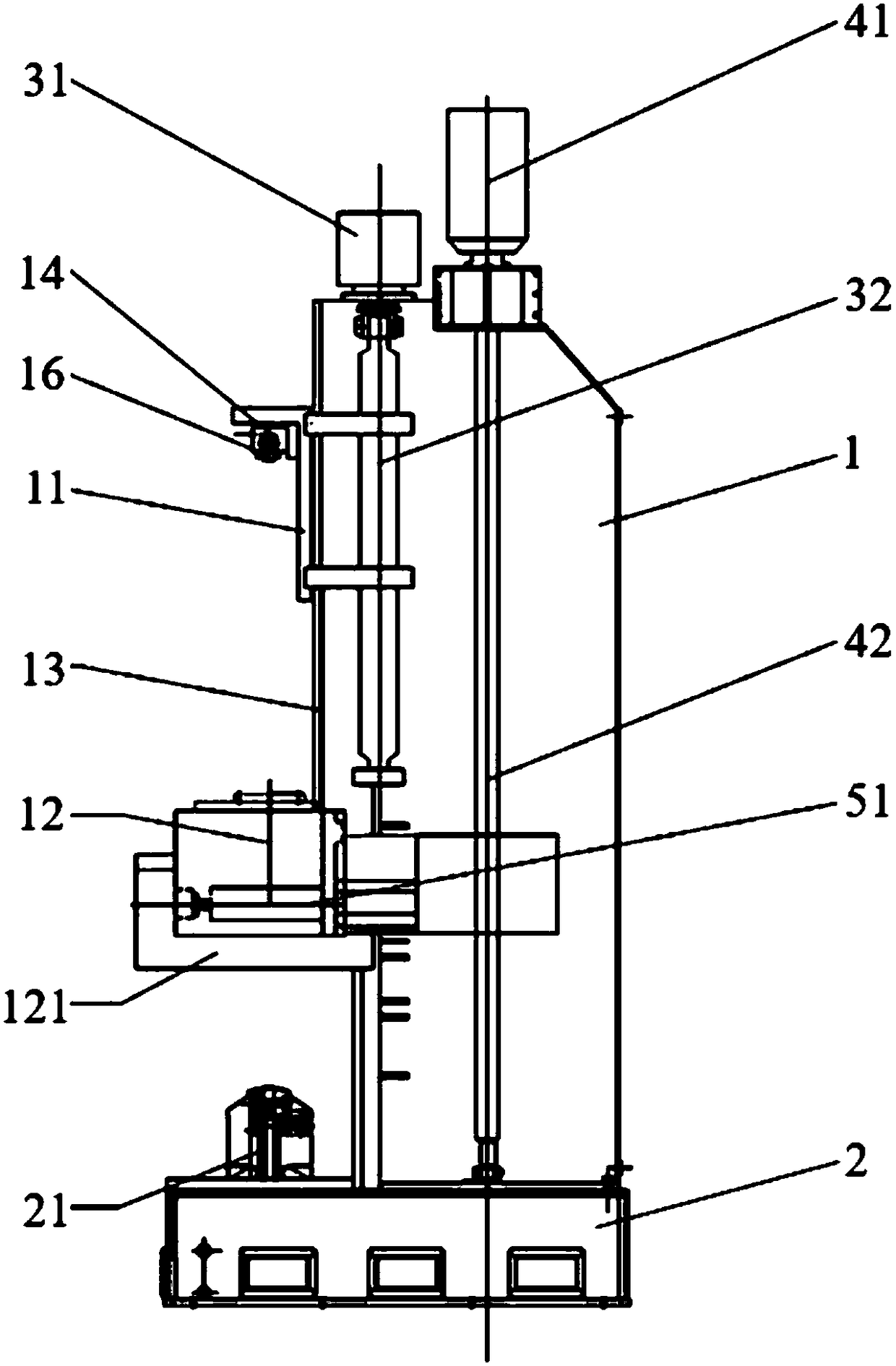

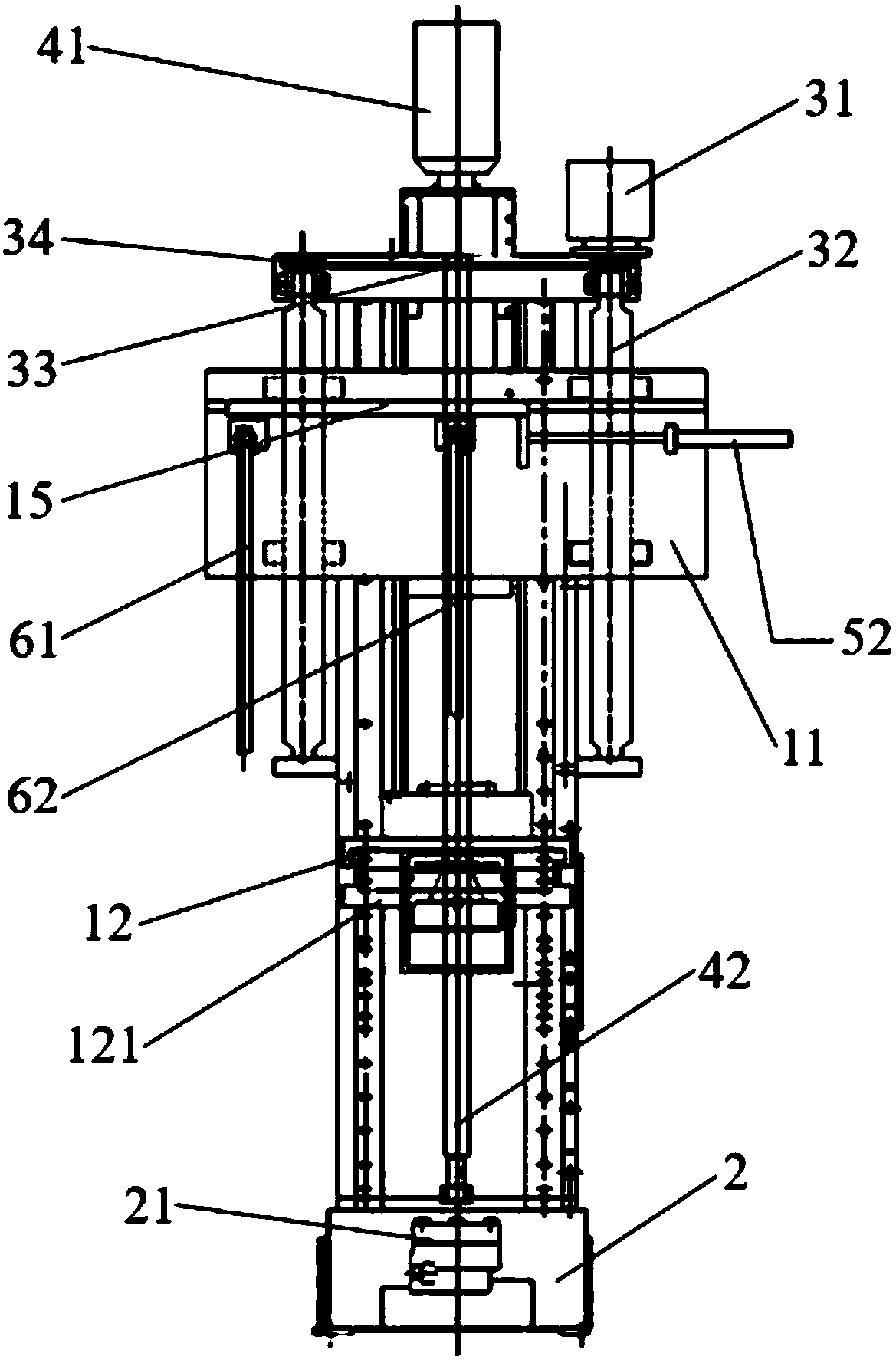

[0038] Such as figure 1 and figure 2 As shown, a device for broaching splines provided by the present invention includes a bed 1, a base 2 and a driving mechanism, wherein:

[0039] The driving mechanism can be driven by air pressure, hydraulic pressure or motor.

[0040] The bed 1 is provided with a main slide plate 11, a workbench 12, a bed platform 121, a bed guide rail 13, a knife feed guide rail 14 and a knife feed device 15, and the main slide plate 11, the workbench 12 and the bed platform 121 can all move The bed guide rail 13 on the body 1 moves up and down, the worktable 12 can clamp the workpiece, and the knife feeding device 15 is equipped with at least two broaches, and the knife feeding device 15 can drive any broach to slide and connect to the main slide 11 superior.

[0041] Spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com