Clamping device for machining thin-walled disc part

A technology of clamping device and thin-walled disk, which is applied in the direction of clamping device, metal processing machinery parts, positioning device, etc., can solve the problems of low product precision, affecting the appearance of parts, and poor clamping rigidity, so as to improve processing efficiency, The effect of improving processing quality and reducing the number of clamping times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

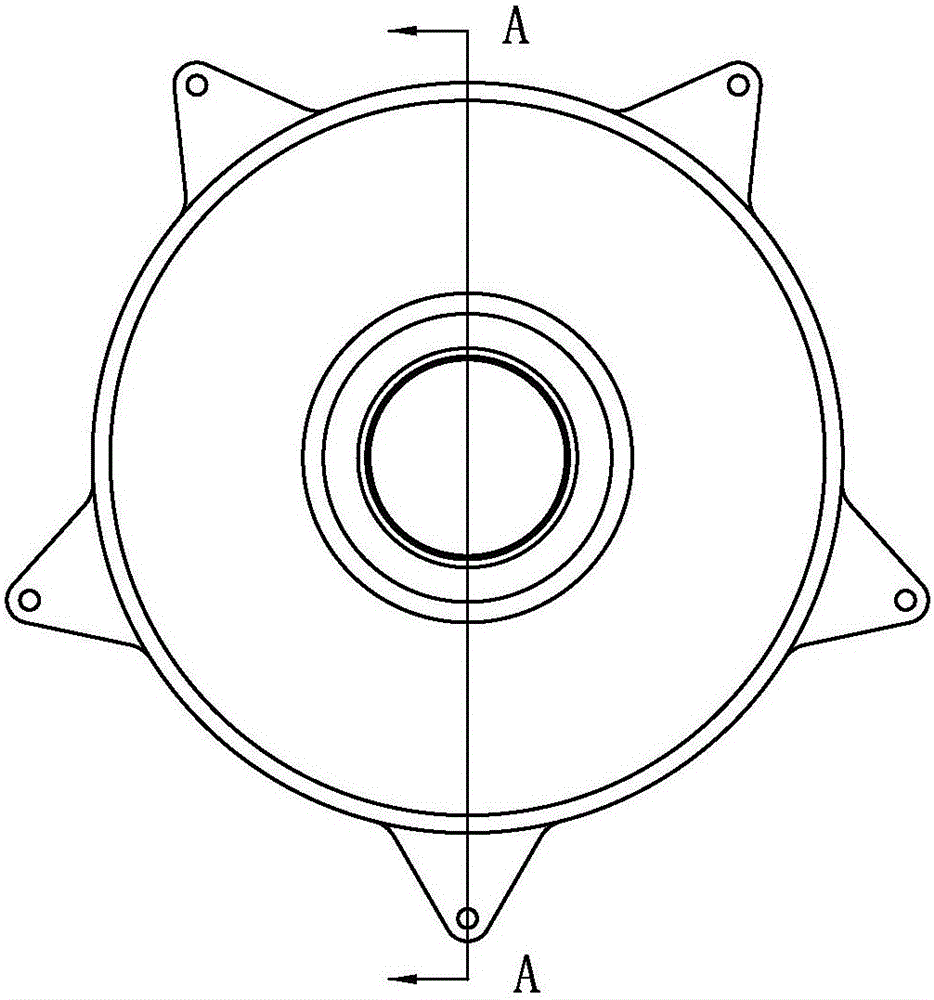

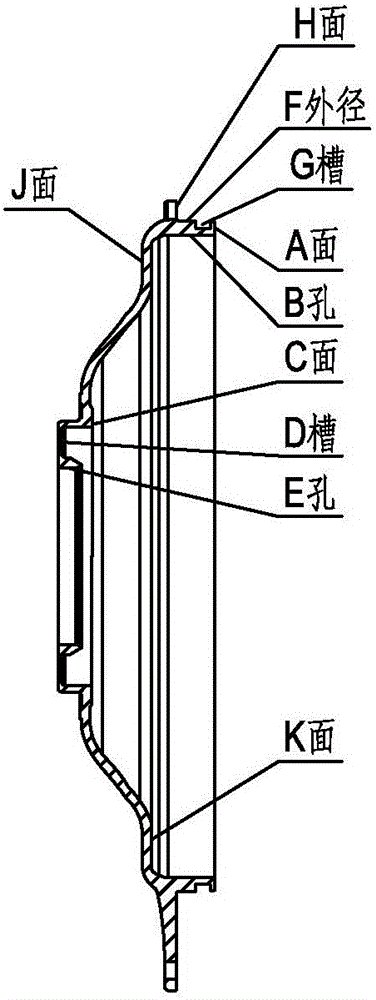

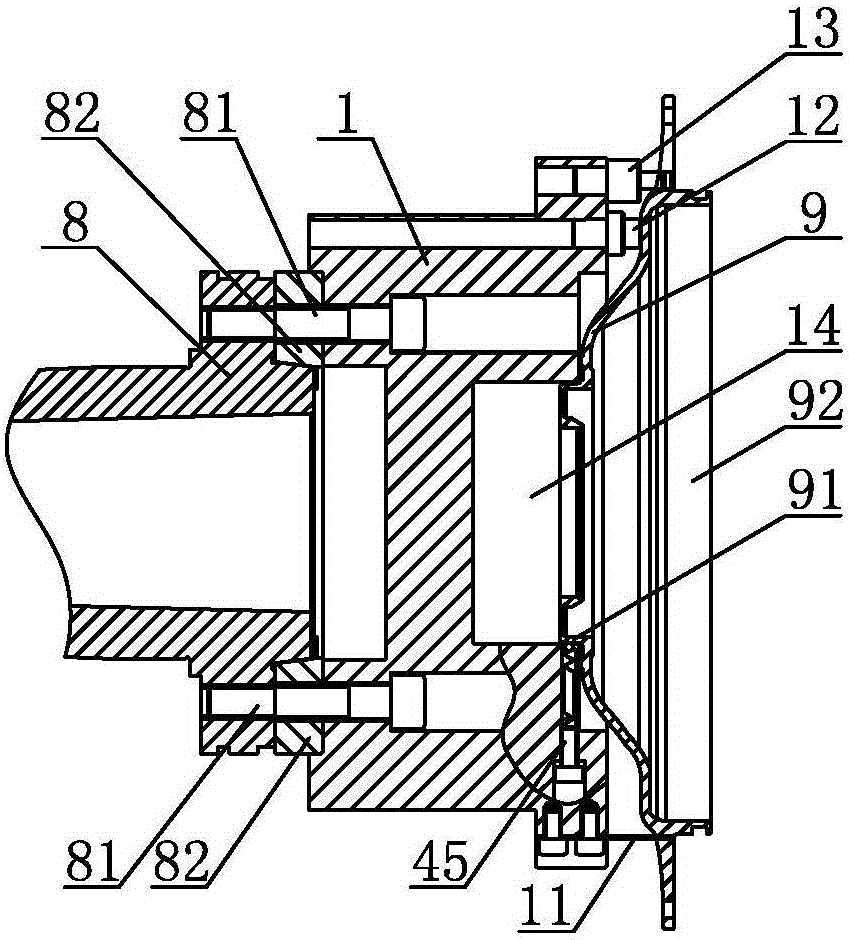

[0021] The clamping device for processing thin-walled disk parts of embodiment 1, such as Figure 3 ~ Figure 7 As shown, it includes a preliminary clamping mechanism and an automatic clamping mechanism. The preliminary clamping mechanism includes a columnar clamping body 1. The clamping body 1 is installed and fixed on the front end of the machine tool spindle 8 through a screw 81. Between the machine tool spindle 8 and the clamping body 1, a A2-6 packing 82, the front end of clamp body 1 is fixed with three pre-clamping pieces 11, three end face positioning posts 12 and one angular positioning post 13, three pre-clamping sheets 11 and three end face positioning posts 12 are respectively Distributed at equal intervals along the circumference of the front end surface of the clamp body 1, the angular positioning columns 13 are located outside the three end surface positioning columns 12, and the front part of the clamp body 1 is provided with an axial concave hole 14, and the dia...

Embodiment 2

[0024] The clamping device for processing thin-walled disk parts in embodiment 2 is generally the same in structure as the clamping device in embodiment 1, the difference is that in embodiment 2, the periphery of the front end surface of the floating gland 5 is protruding The first arc surface 51, the inner side of the rear end face of the rotary gland 4 is the second arc surface 46 protruding forward, the first arc surface 51 is in contact with the second arc surface 46, the first arc surface 51 The diameters of the second arc surface 46 and the second arc surface 46 are both 375 mm.

[0025] When the above clamping device is clamped, the middle boss 91 of the thin-walled disc blank part 9 is used as the center, and the middle boss 91 is inserted into the axial concave hole 14, and the part 9 is clamped by three pre-clamping pieces 11. At the same time, the contact between three end face positioning columns 12 and the J surface of the part 9 is used as axial positioning, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com