Welding production line with matched clamp

A welding production line and accompanying fixture technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult welding technology and high welding quality requirements, and meet the requirements of reducing positioning requirements and repeatability. The effect of comprehensive welding processing and effective combined use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

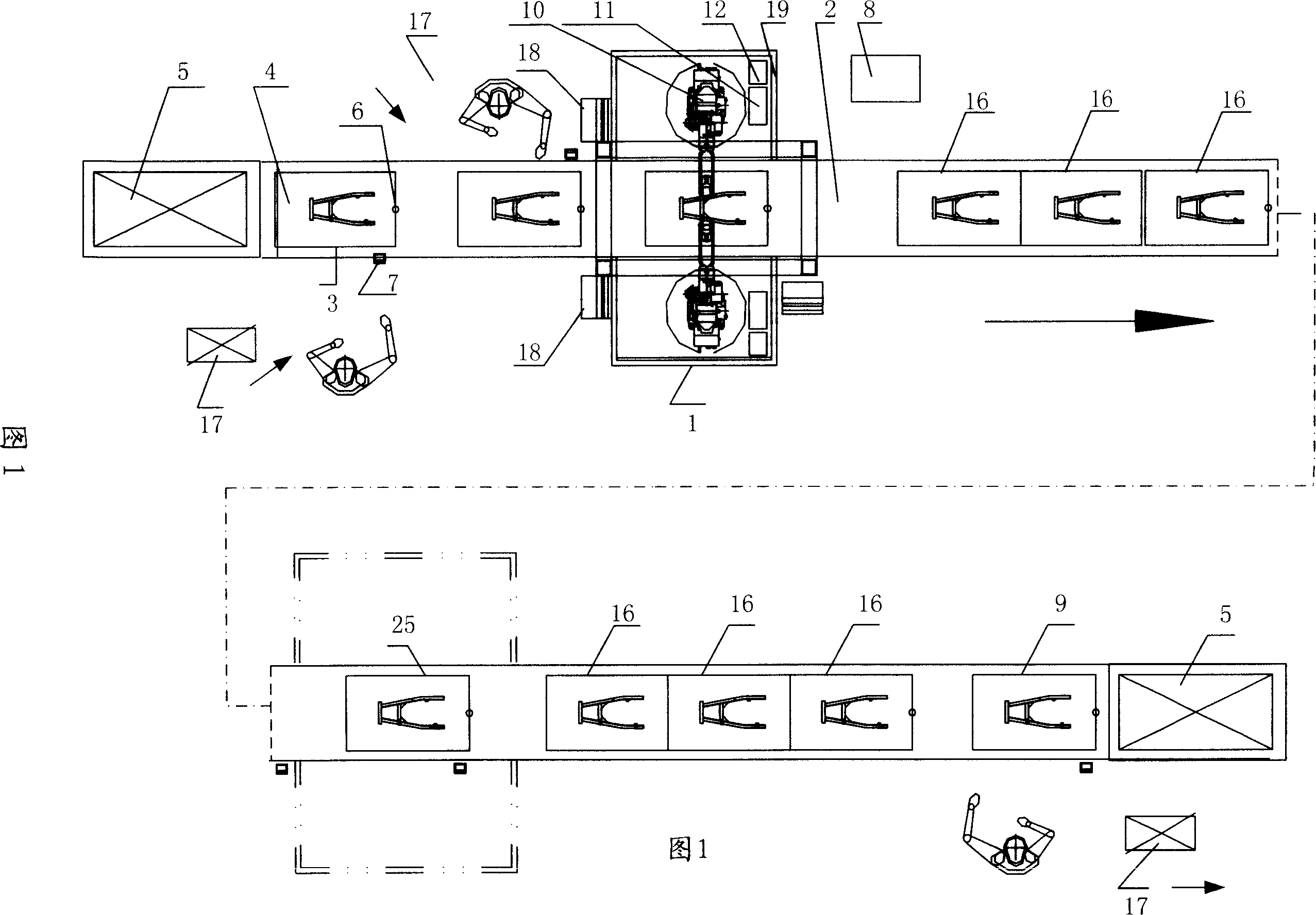

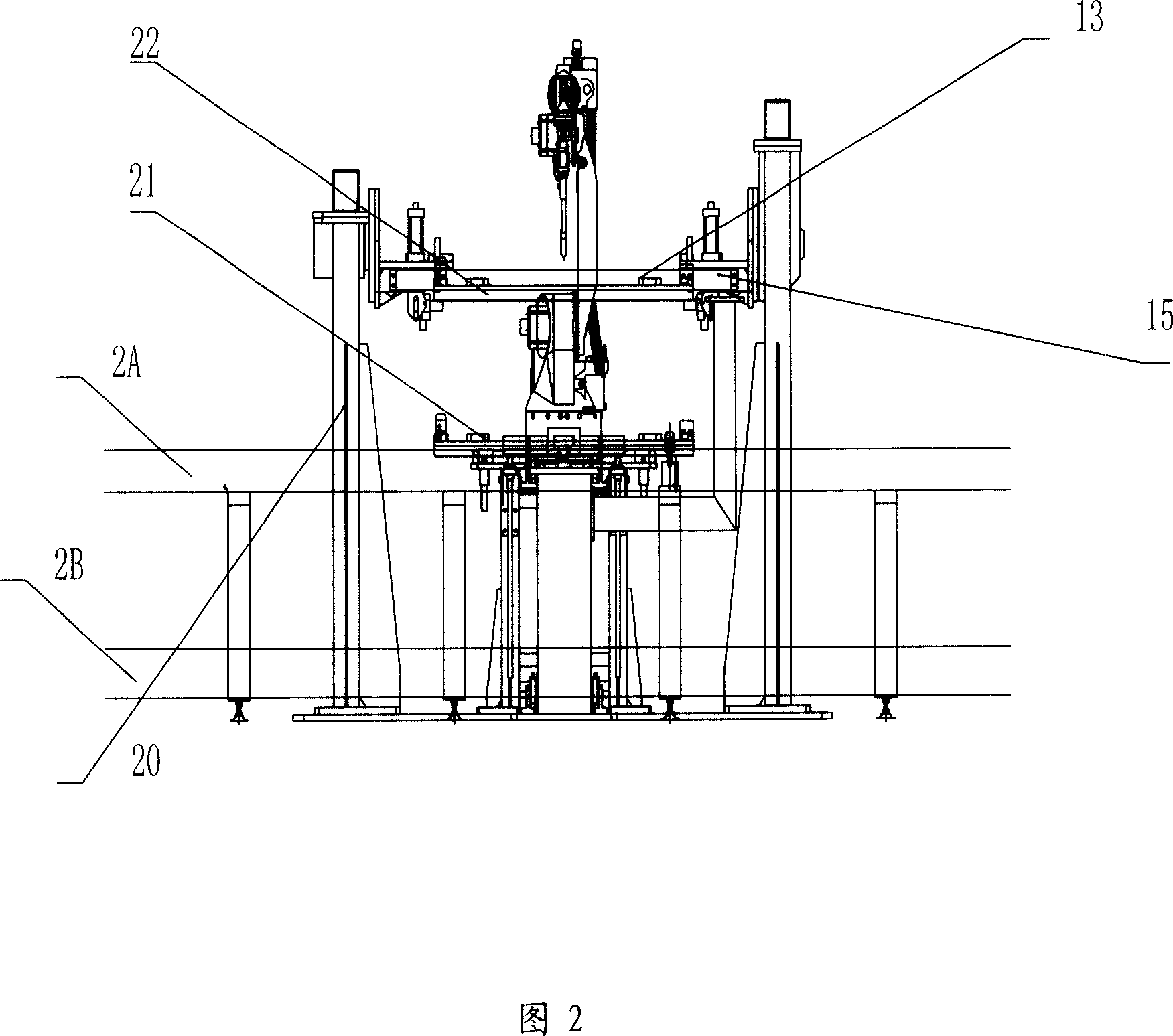

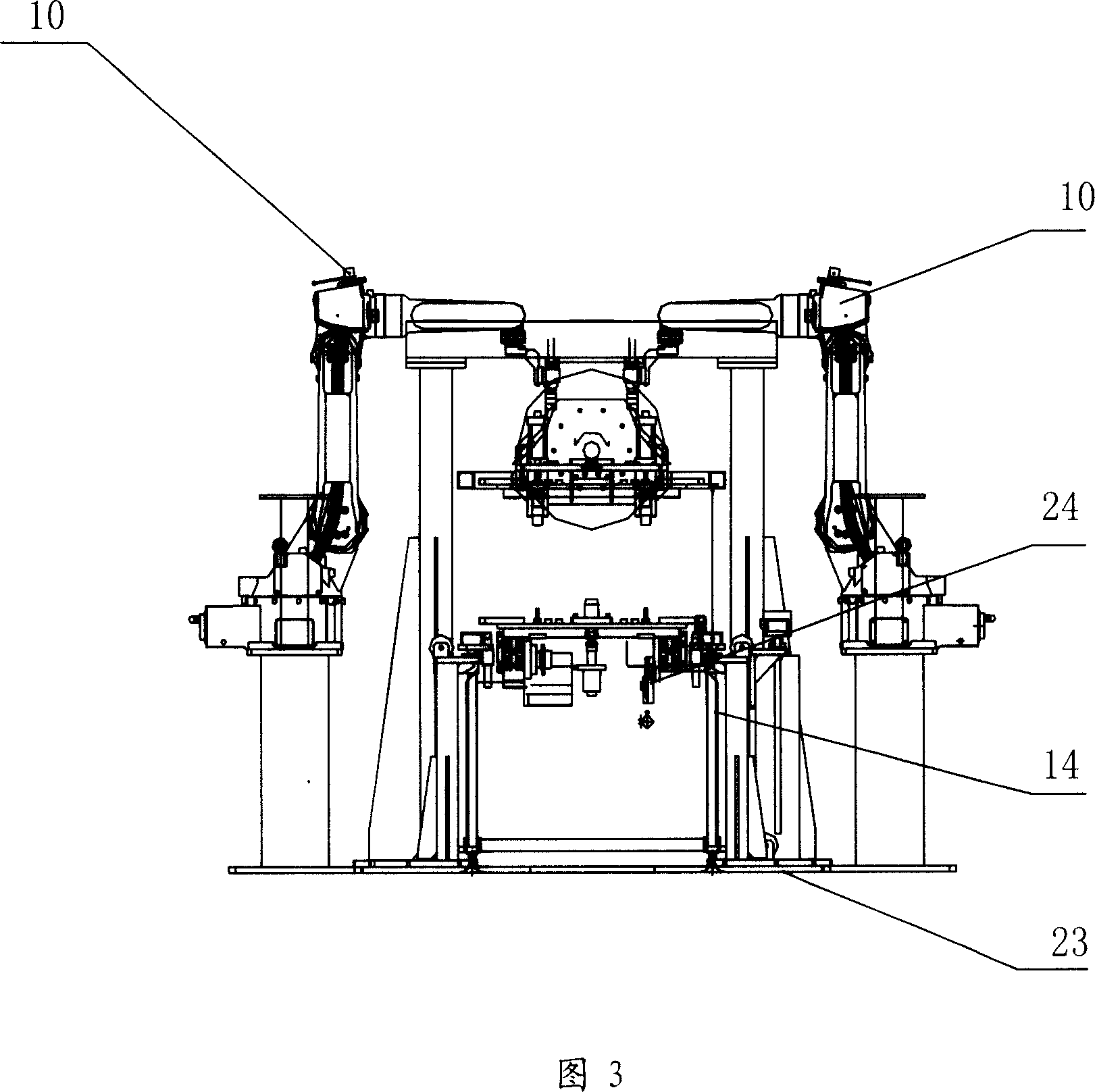

[0028] Referring to Figures 1 to 3, the welding production line with accompanying fixtures in the present invention includes a welding robot station 1 (including a robot 10, a control cabinet 11, an operating table 18, a robot welding power supply 12, a robot workstation base 23, and a workstation fence 19) , Transmission line 2, accompanying welding fixture 4, elevator 5, stopper 6, manual foot switch 7, and total control cabinet 8. Wherein the robot station 1 also includes a positioner 13 , a positioner support 20 , a quick clamping device 15 , a lifting mechanism 14 and a protection device 24 . Its working principle is as follows: the lifting mechanism 14 lifts the accompanying welding jig 4 and its workpiece on the transmission line 2 to the same height as the positioner 13, and separates it from the transmission line 2. At this time, the quick clamping device 15 lifts the accompanying welding jig 4 4 and its workpiece are clamped and accurately positioned on the positione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com