Engine cylinder head numerical control machine for floating ship

A technology for engine cylinder heads and CNC machine tools, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., and can solve problems such as low processing accuracy and efficiency, complex internal hole structure, and frequent clamping of workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

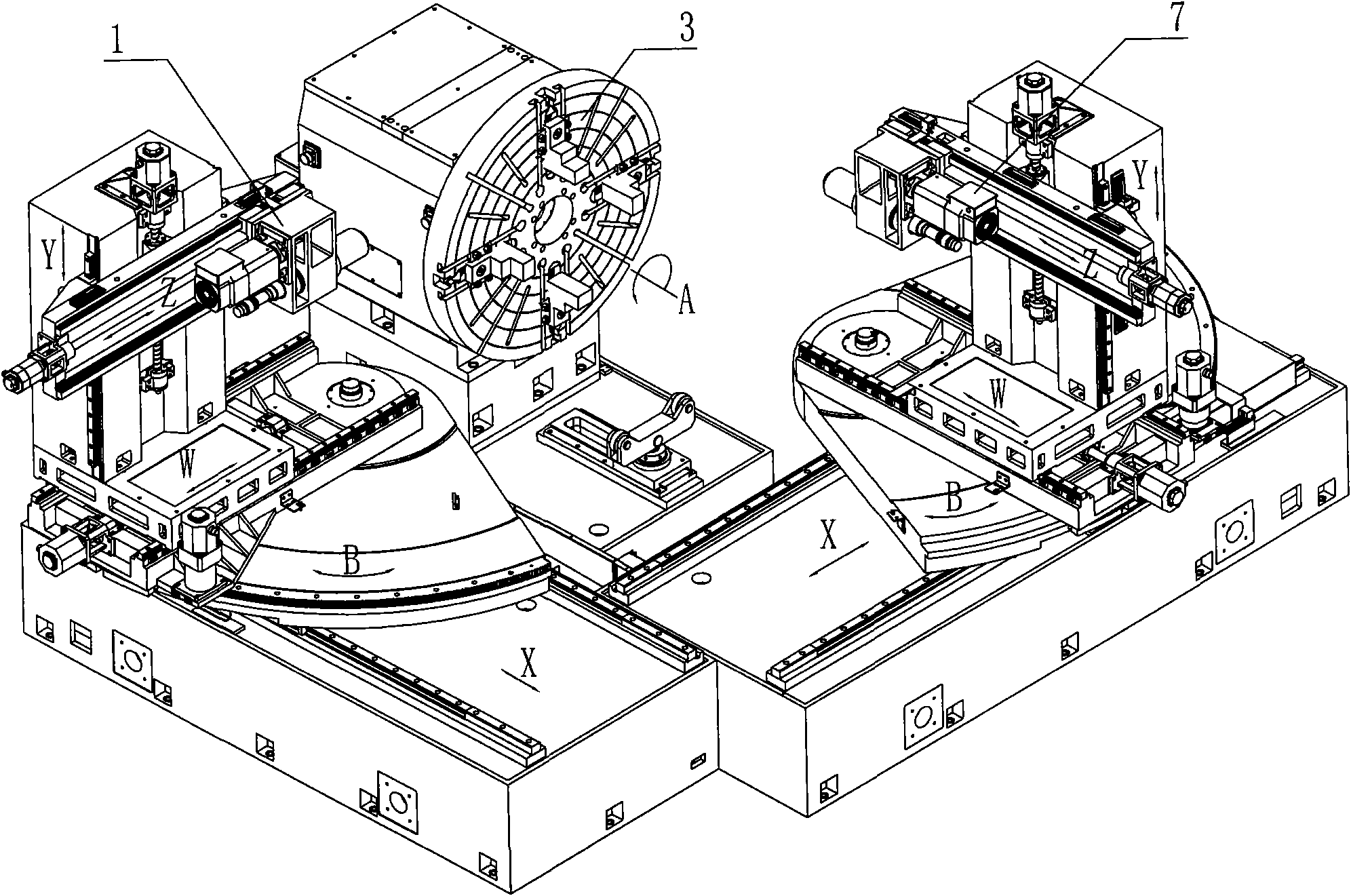

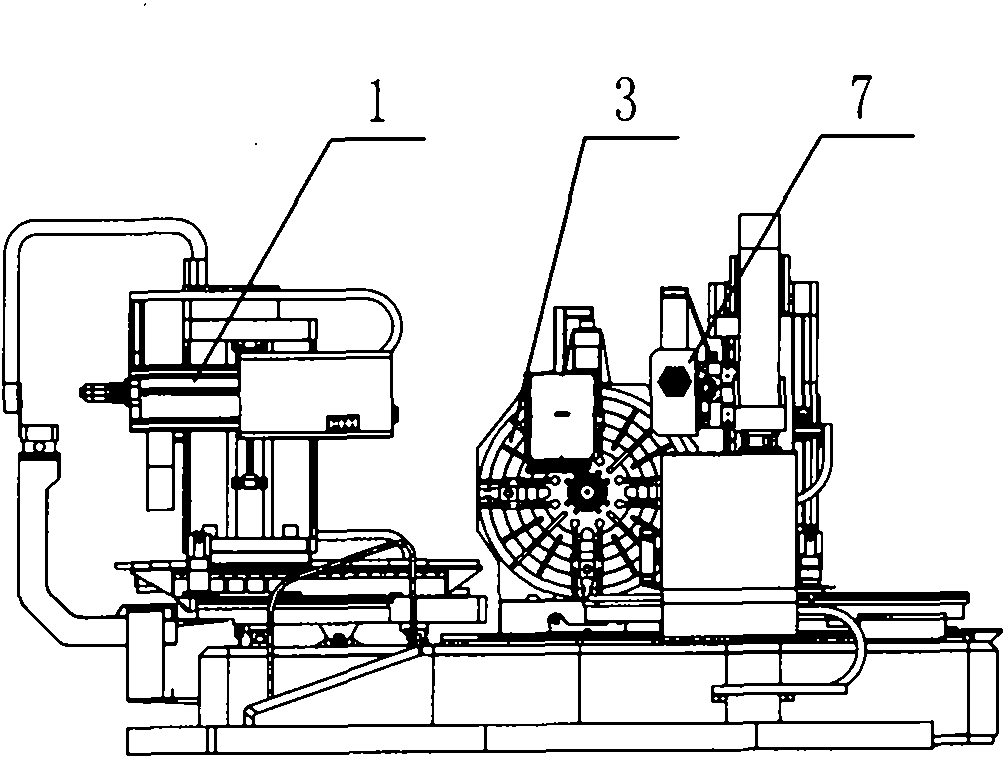

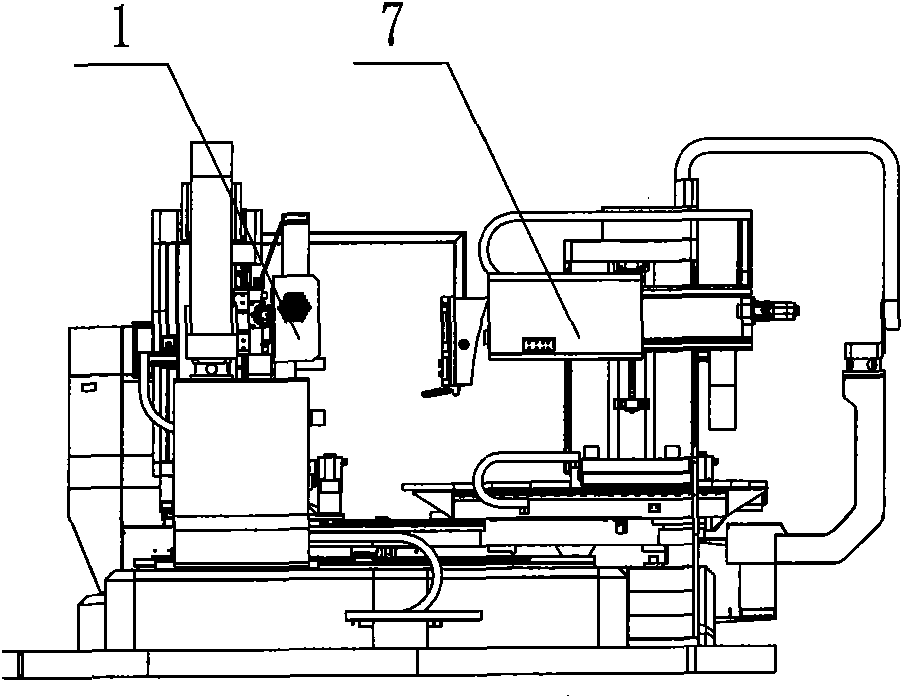

[0026] CNC machine tools for processing marine engine cylinder heads, including electrical control system 2, hydraulic system 4, chip removal 6 and cooling and filtering system 5, from Figure 1-4 The relationship between the five axes of the axial processing unit and the radial processing unit and the A-axis fixed by the fixture can be seen as a whole, and it is characterized in that the radial processing unit 1, the axial processing unit 7, and the high-precision A-axis indexing fixture 3 They are independent devices. The radial processing unit 1 is located on the side of the high-precision A-axis indexing fixture 3, and the axial processing unit 7 is located directly opposite the high-precision A-axis indexing fixture 3. Through a set of electrical control system 2, hydraulic pressure System 4, chip removal 6 and cooling filter system 5 and protective enclosure, see Figure 4 , the three devices constitute a complete special-purpose CNC machine tool; the structure of the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com