High-speed aviation rotor blade tip grinding machine

A rotor and aviation technology, applied in grinding machines, grinding bed, grinding machine parts, etc., can solve problems affecting the working efficiency and reliability of the engine, poor consistency of the rotor tip, and difficulty in controlling the clearance between the tip and the casing and other problems to achieve the effect of improving processing quality, improving processing efficiency and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

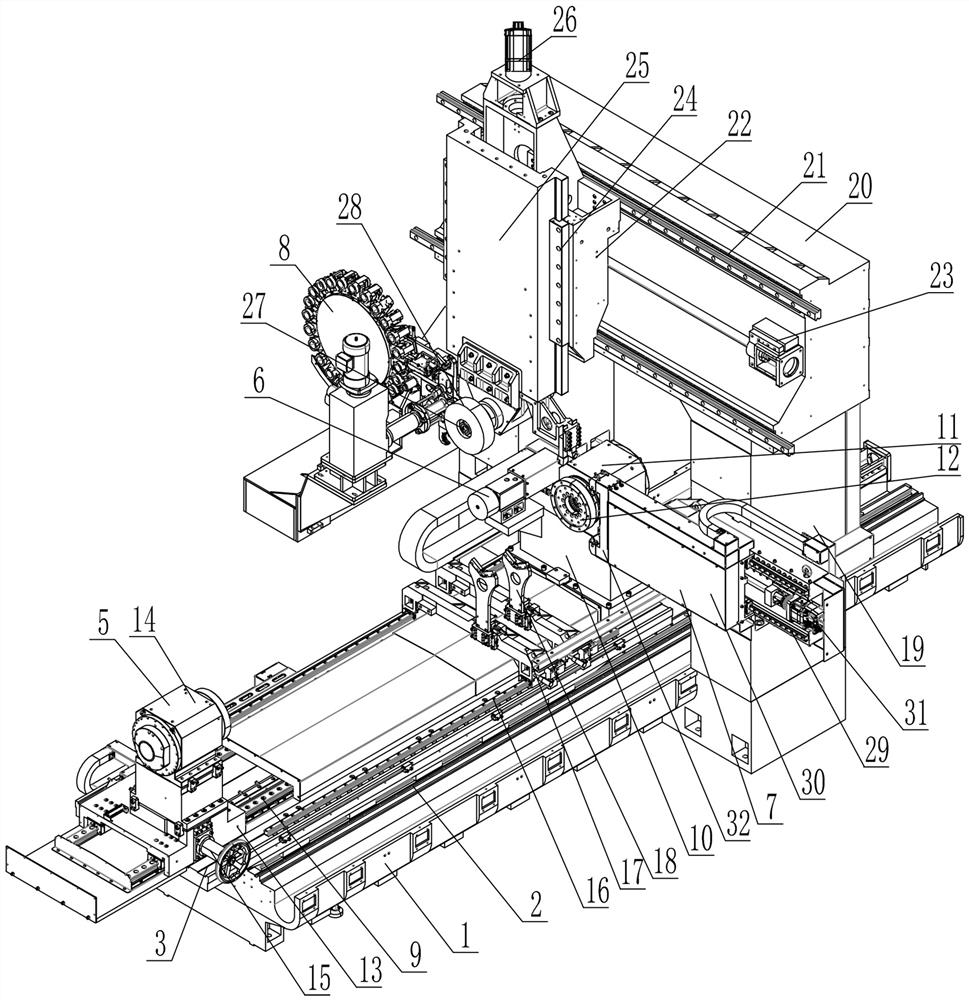

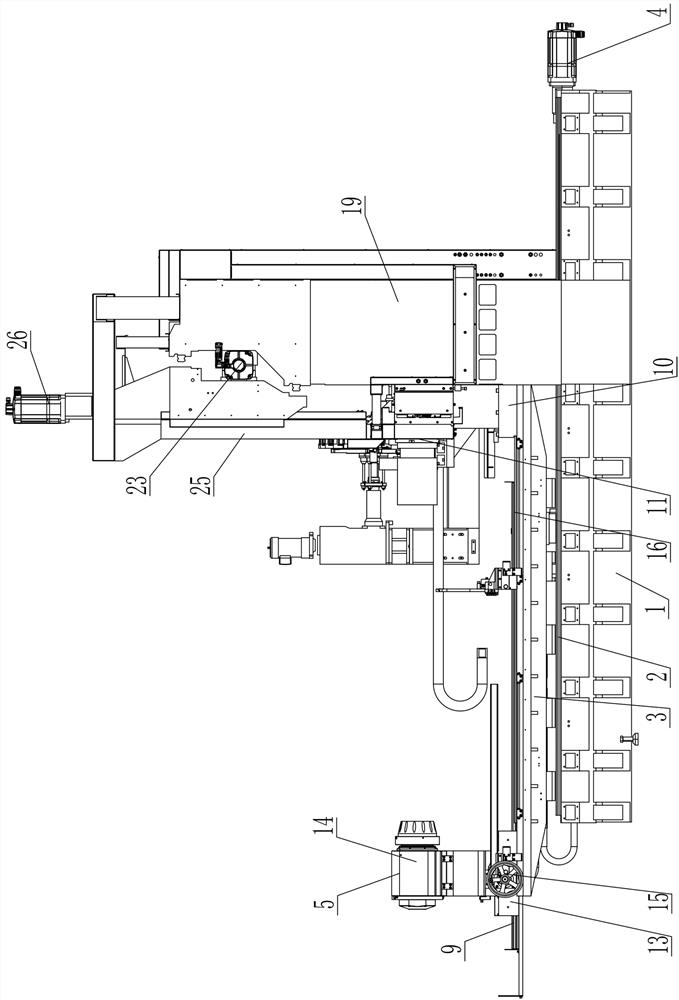

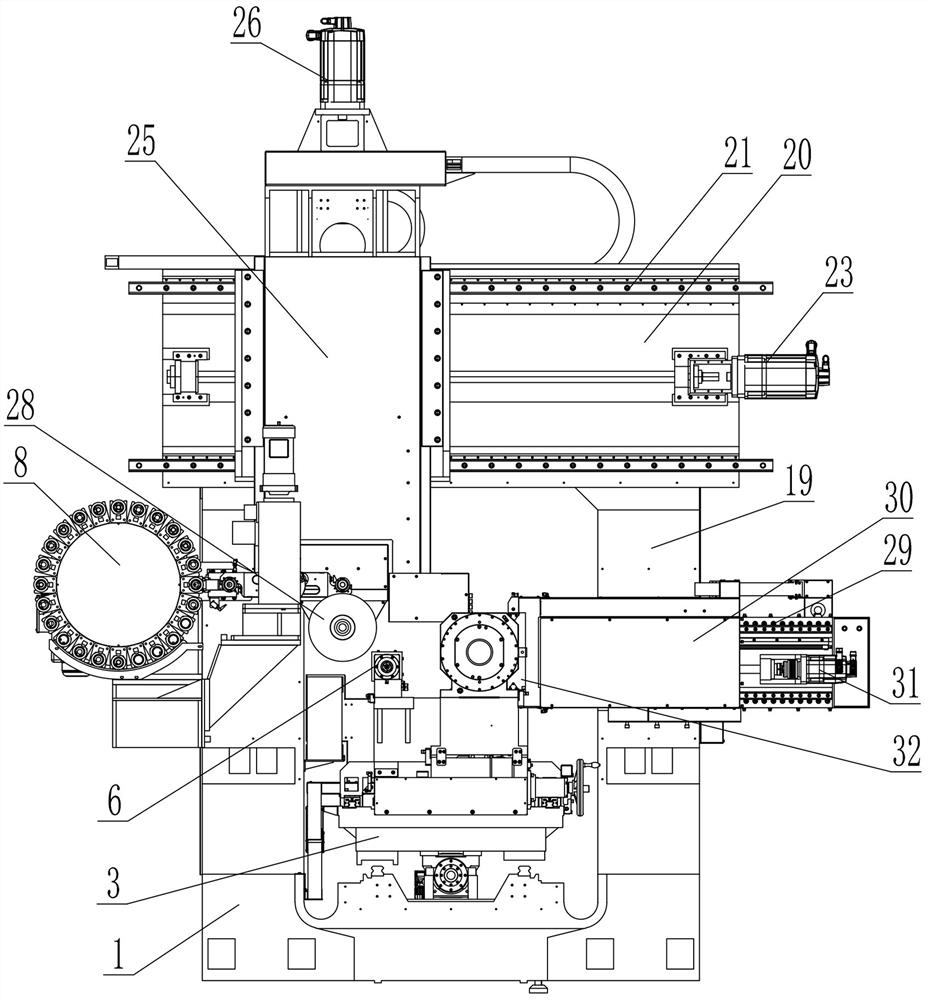

[0029] The following will be combined with Figure 1-4 The present invention is described in further detail.

[0030] A high-speed aviation rotor blade tip grinder, comprising a base 1 arranged horizontally, on which an X-axis guide rail 2 arranged horizontally and horizontally is arranged, on which an X-axis moving frame 3 slidingly connected with the X-axis guide rail 2 is arranged, and the base 1 is provided with a first drive mechanism 4 that drives the X-axis moving frame 3 to move on the X-axis guide rail 2. The base 1 can be set to a sufficient length as required, so that the effective moving distance of the X-axis moving frame 3 is large enough, and can be moved out of the processing area of the grinding spindle to facilitate the hoisting of workpieces.

[0031] The X-axis mobile frame 3 is equipped with a spindle clamping mechanism 5 for placing the product to be processed, and the X-axis mobile frame 3 is equipped with a grinding wheel dresser 6, which can correct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com