Multi-head numerical control drilling machine

A CNC drilling machine and multi-head technology, which is applied to the components of the boring machine/drilling machine, boring/drilling, drilling/drilling equipment, etc., can solve the problems of high price, inconvenient maintenance, complex structure, etc. Clear and concise, compact and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

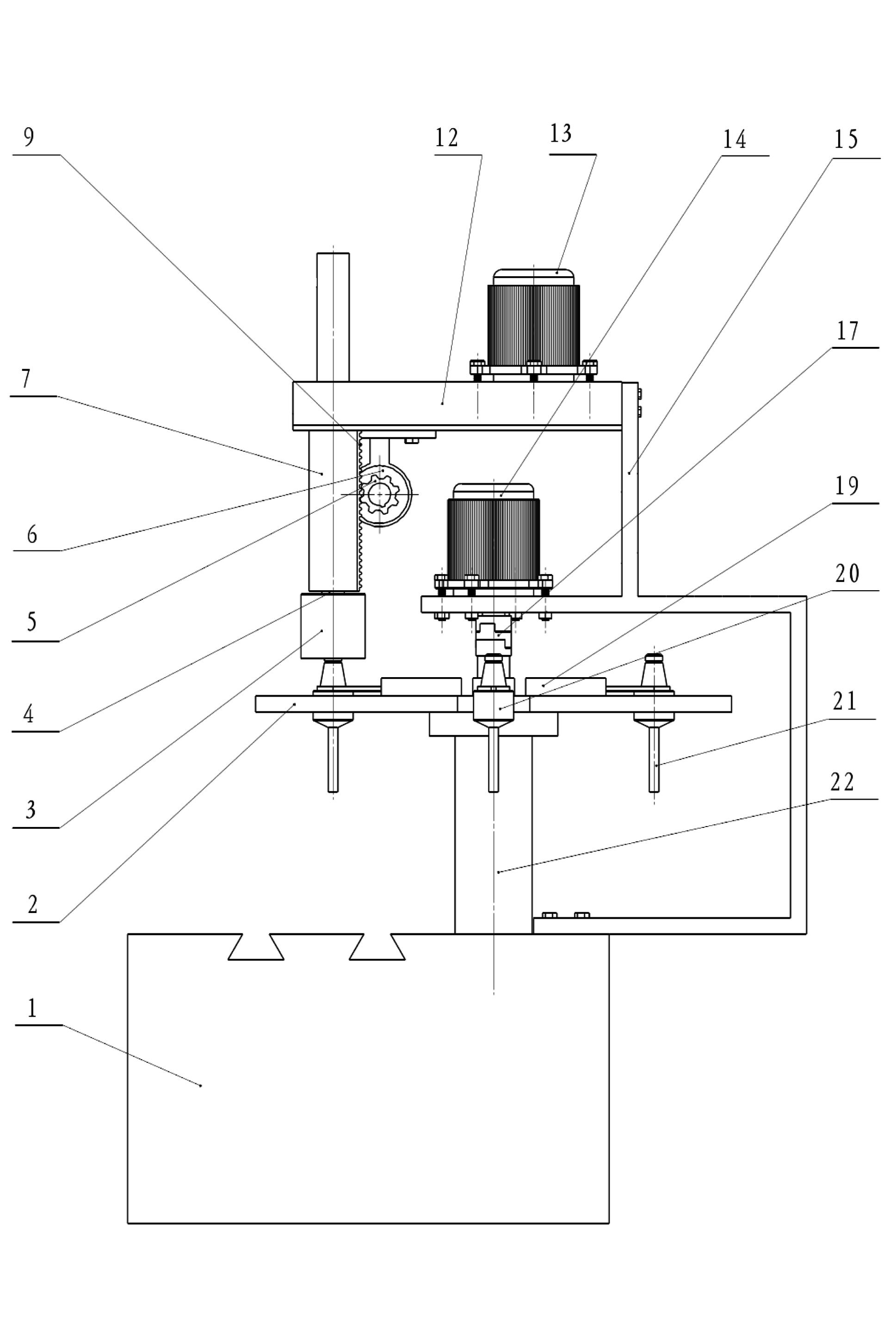

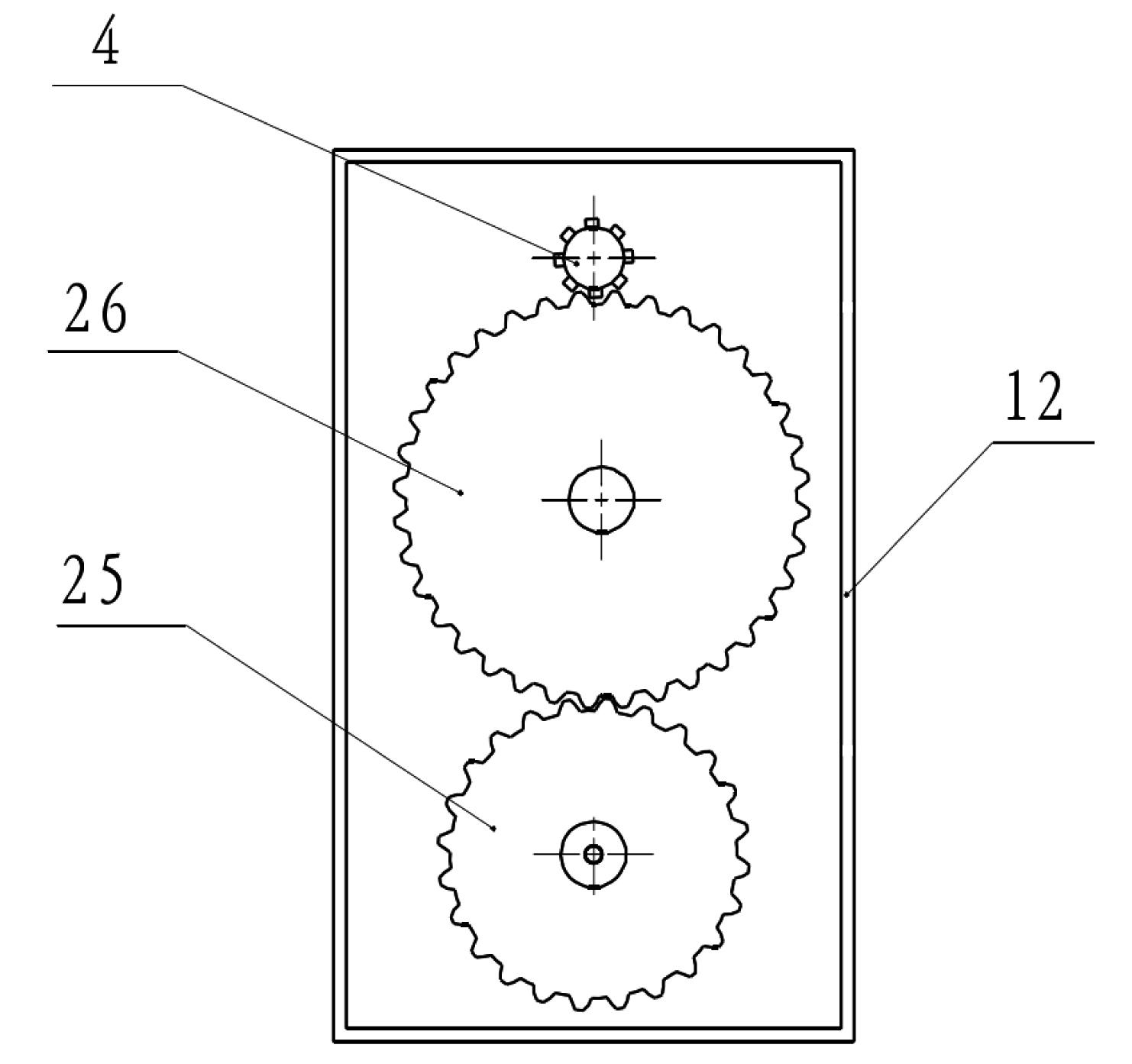

[0030] like figure 1 As shown, the multi-head CNC drilling machine of the present invention includes a base 1, a tool change mechanism, a drill mechanism, and a feed mechanism. A support frame 15 is fixedly arranged, and the support frame 15 is fixedly connected with the base 1 by bolts; the support frame 15 is provided with a drill mechanism, and the drill mechanism is connected to the feed mechanism, and the feed mechanism drives the main shaft cover 7 of the drill mechanism to move in the vertical direction. The pneumatic clamp 3 (the pneumatic clamp 3 clamps the tool bit 21 through the tool holder 20) can move in the vertical direction; the control terminals of the tool changing mechanism, the drill mechanism and the feeding mechanism are all connected to the signal output terminal of the numerical control system.

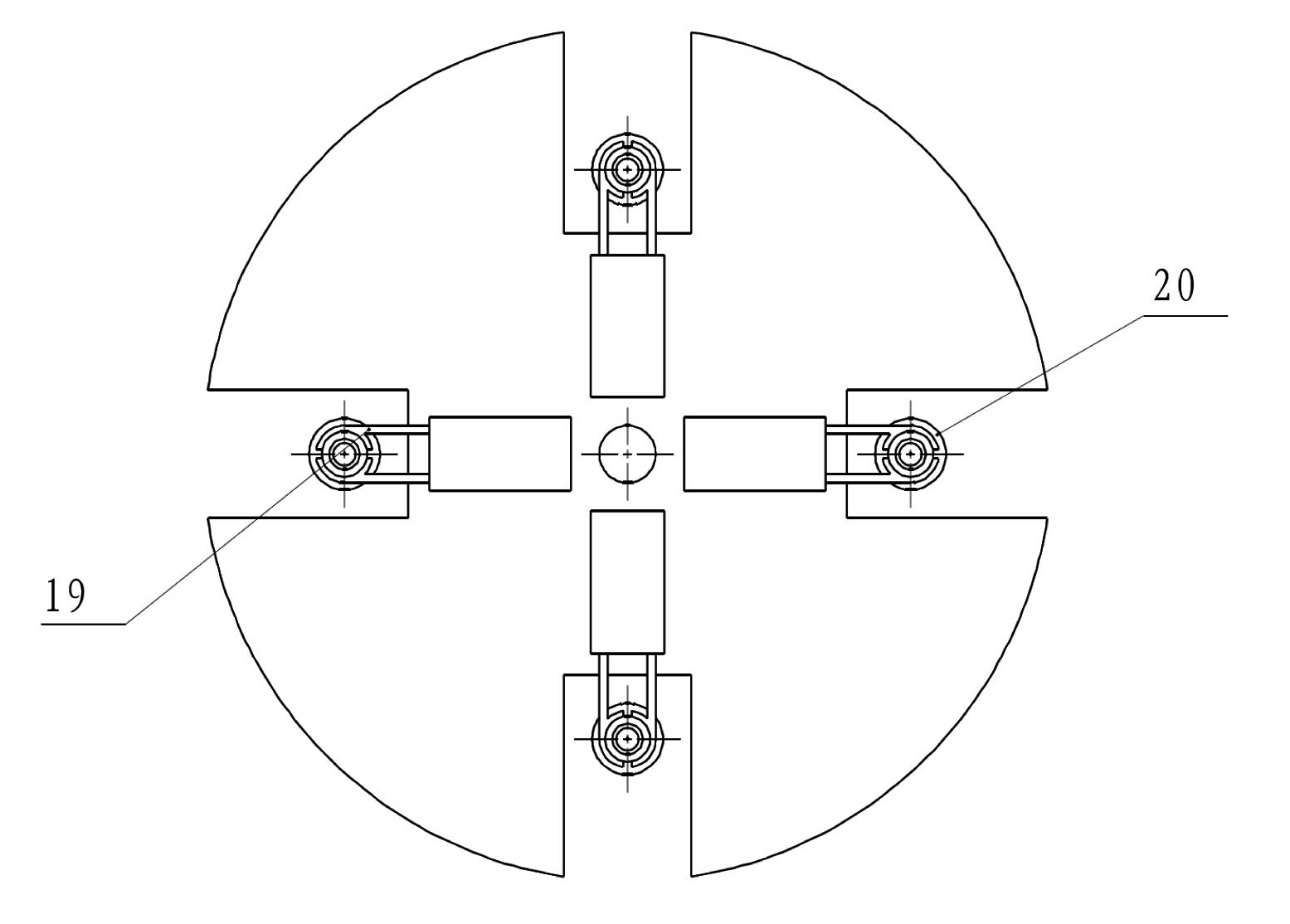

[0031] like figure 2 As shown, the tool changing mechanism includes a disc 2, a manipulator 19, a tool chuck 20, a speed and angle controllable servo motor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com