Base adjusting and fixing mechanism of aircraft titanium alloy part machining tool table

A fixing mechanism and parts processing technology, which is applied in the direction of metal processing equipment, metal processing machinery parts, large fixed members, etc., can solve the problems of high work intensity, low clamping efficiency, and difficult processing of workers, so as to improve applicability and Flexibility, improved processing efficiency, and improved repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and example the present invention will be further described:

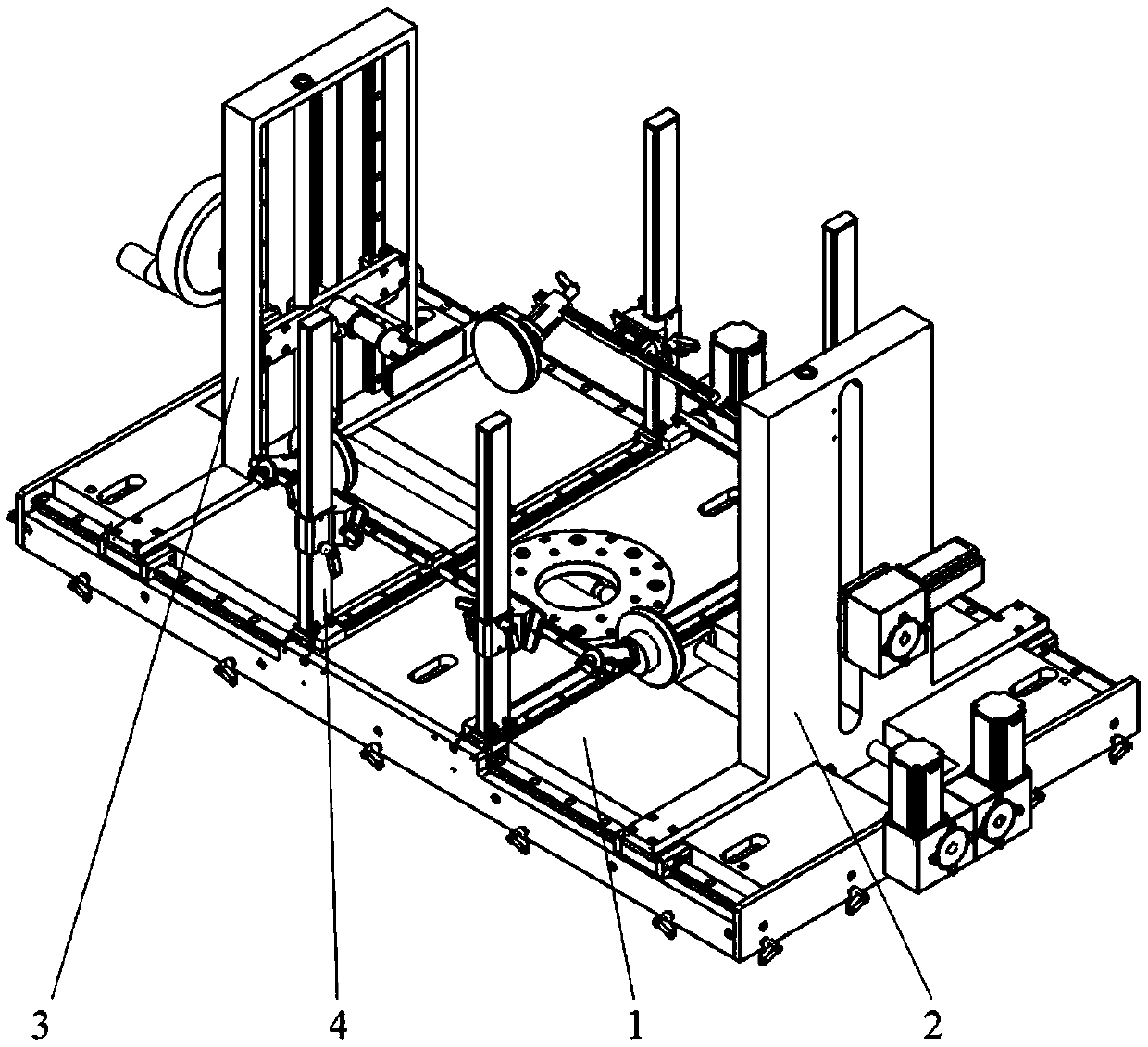

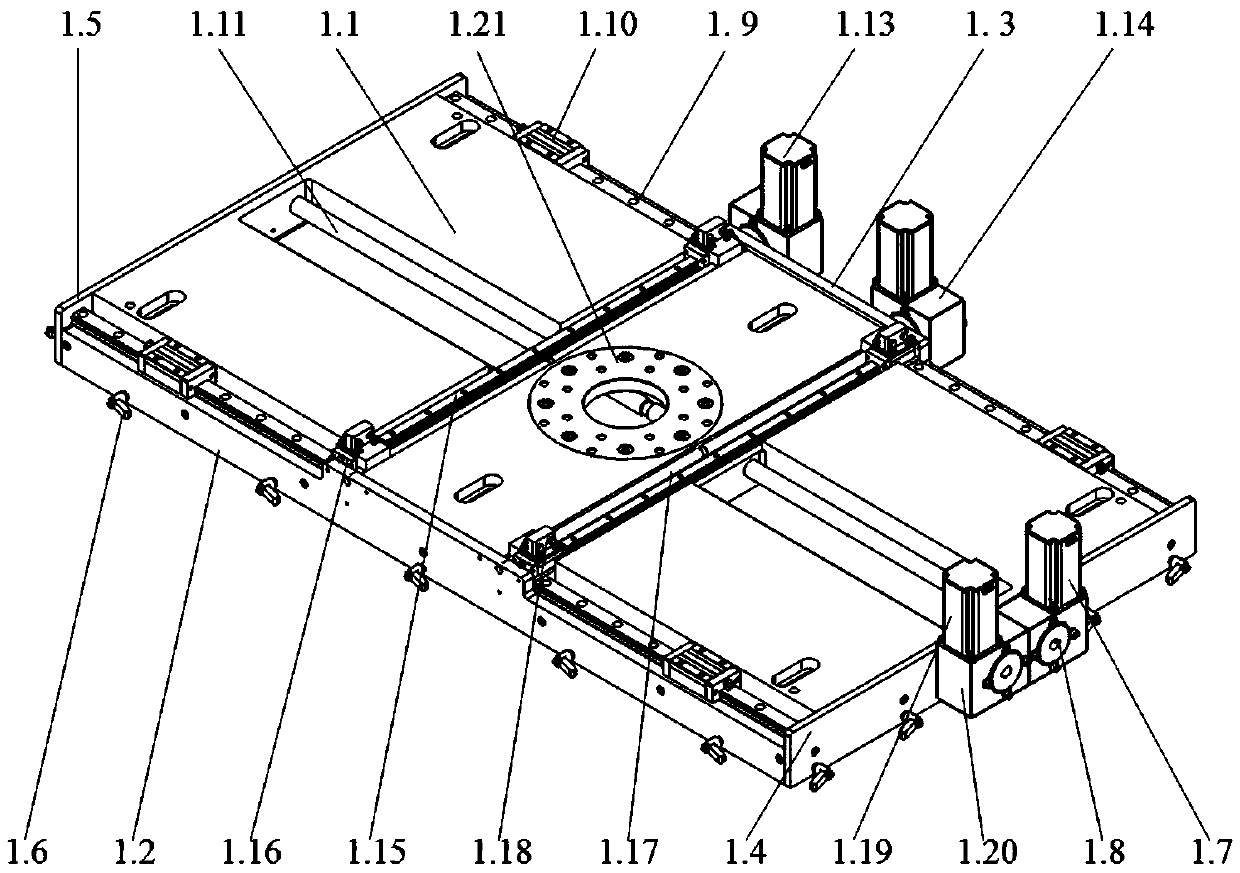

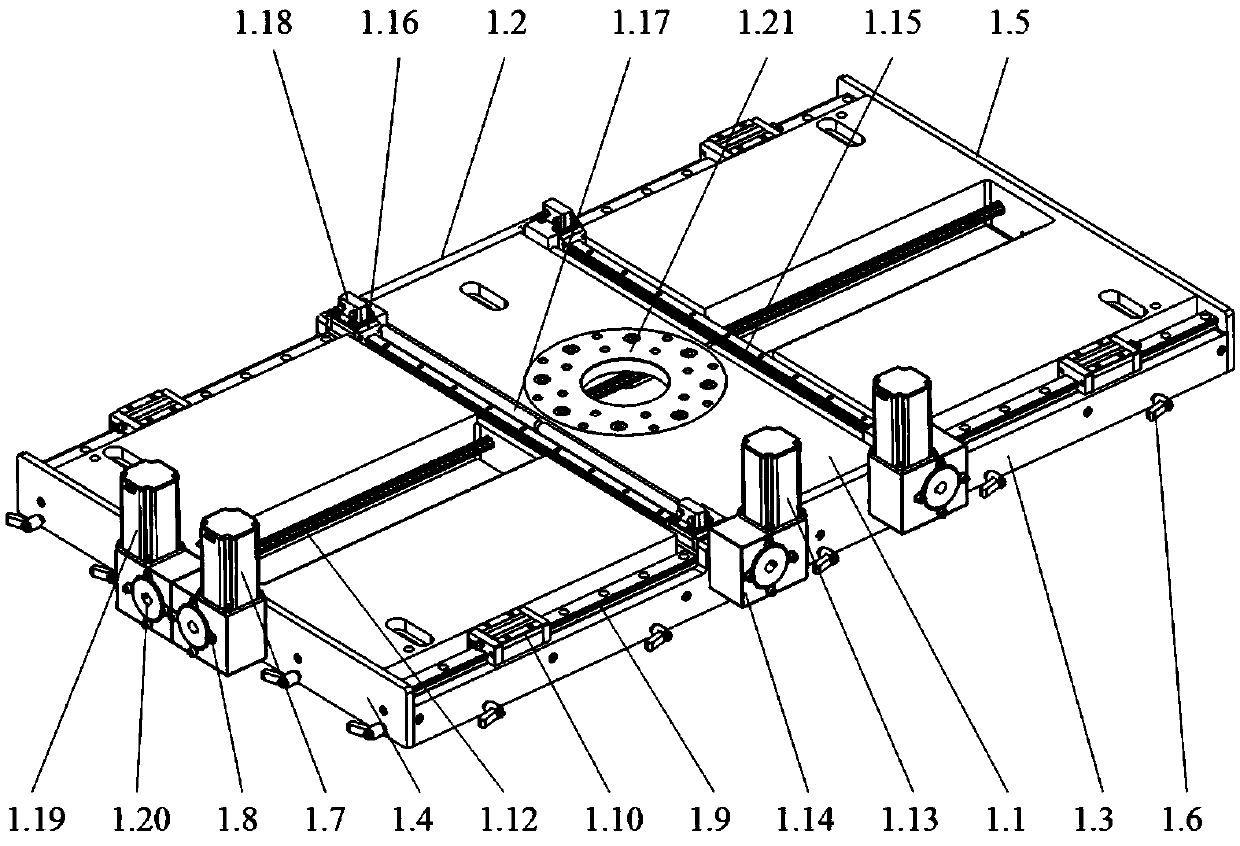

[0034] Such as figure 1 - Figure 11As shown, the base adjustment and fixing mechanism of an aircraft titanium alloy parts processing tooling platform according to the present invention includes four parts, namely the base adjustment and fixing mechanism 1, the left lifting and pressing mechanism 2, and the right lifting and pressing mechanism 3 and the X-direction pressing mechanism 4, the base adjustment and fixing mechanism 1 is installed and fixed on the working platform of the machine tool with screws, and the left lifting and pressing mechanism 2 and the right lifting and pressing mechanism 3 are installed and fixed on the base seat adjustment and fixing mechanism 1, and form a threaded transmission and a spline transmission and a sliding fit connection relationship with the base adjustment and fixing mechanism 1. The X-direction pressing mechanism 4 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com