Double-faced processing combined machine tool

A combined machine tool and double-sided processing technology, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of multi-station processing, low processing accuracy, and high labor intensity, so as to reduce energy consumption, The effect of improving machining accuracy and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

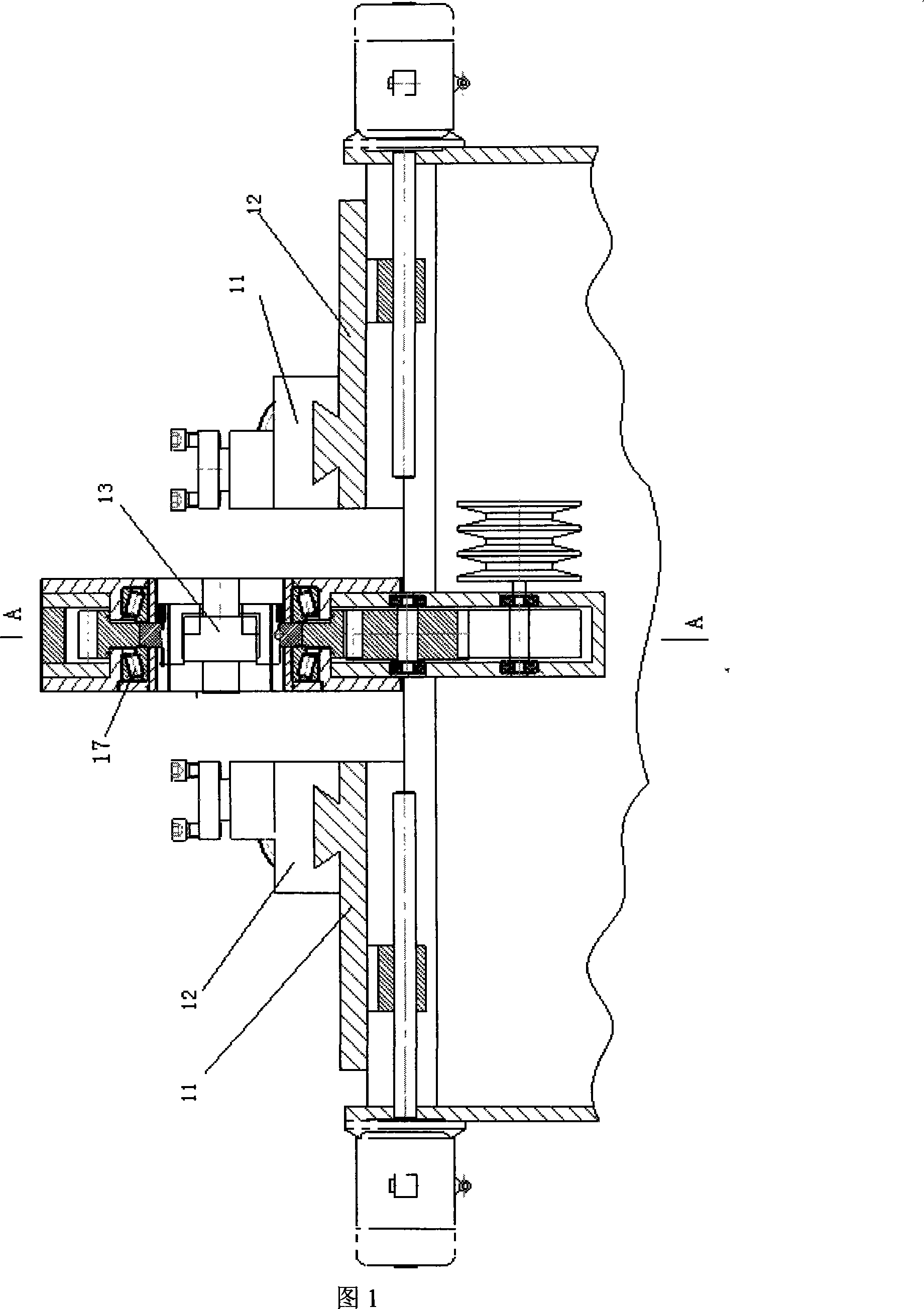

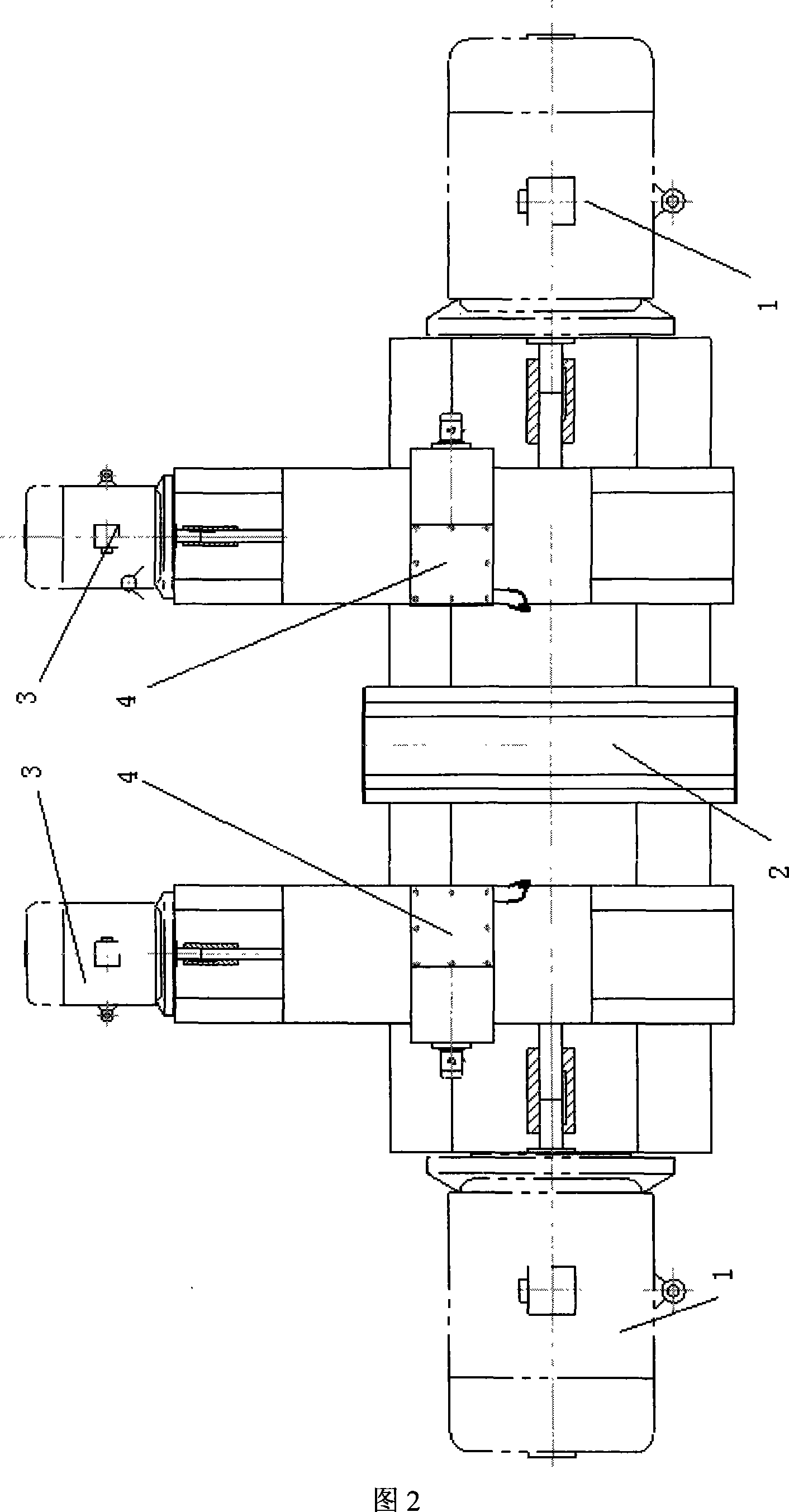

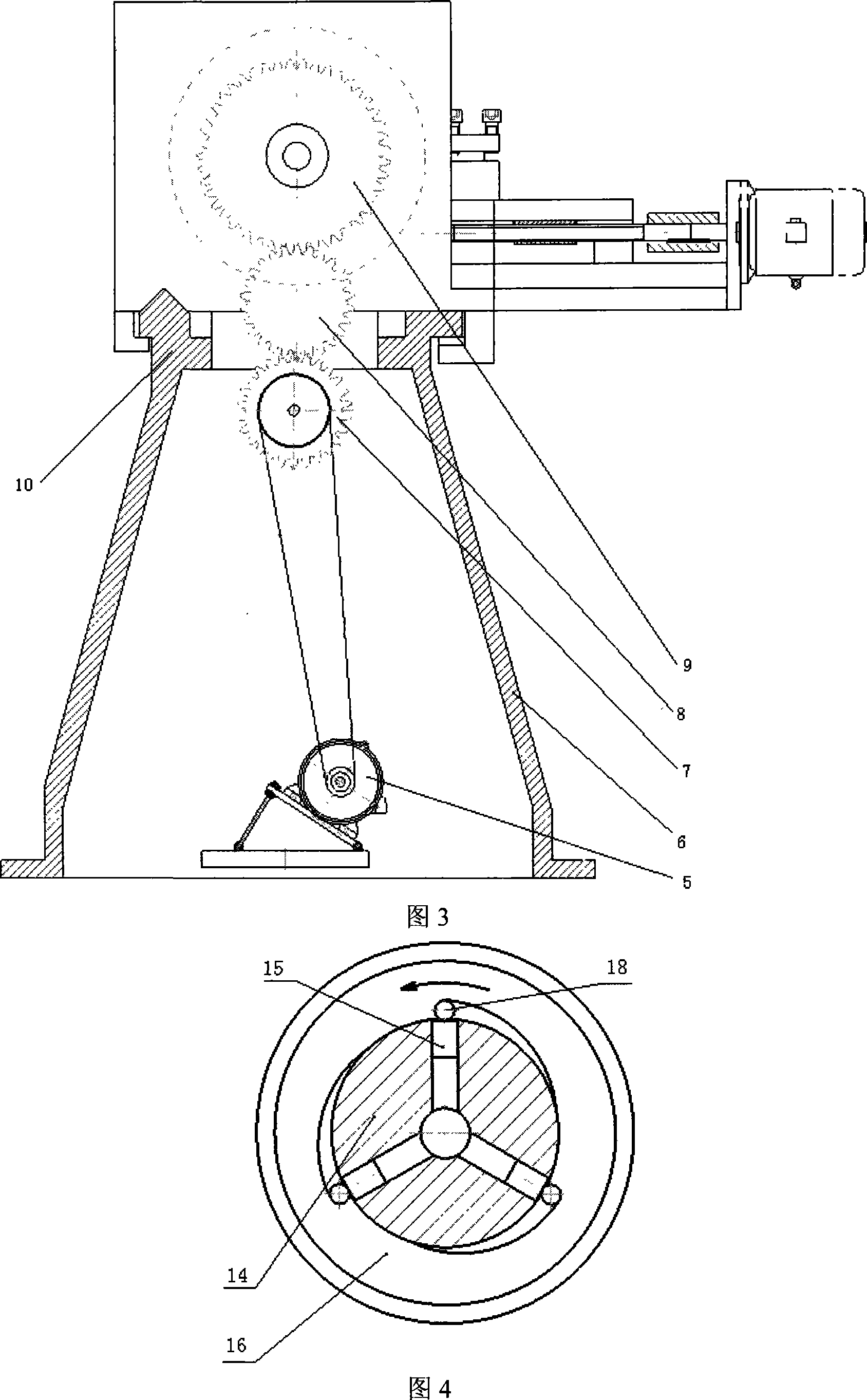

[0016] 1, 2, 3, and 4, the box body 2 is fixed on the bed 6, the motor 5 drives the sleeve 16 to rotate through the connecting gears 7, 8, and 9, the main shaft 14 drives the workpiece to rotate by rolling the shaft 18 on the slope of the sleeve 16, and The workpiece 13 is clamped by the block 15. The box body 2 and the sleeve 16 are connected by the bearing 17.

[0017] Two large slides 11 are respectively arranged on the bed 6 on both sides of the box body 2, and each large slide 11 is driven by a servo motor 1 for longitudinal feeding, and a small slide is arranged on each of the two large slides 11 12. The small slide 12 is driven by the servo motor 3 to perform lateral feed on the large slide 11, and the tool holder 4 clamps the tool to realize various processing of the workpiece 13 with the action of the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com