Ultrahard-material special-shaped component tensioning positioning tool assembly and milling method

A technology of special-shaped components and superhard materials, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult to guarantee processing quality, weak rigidity, loss of accuracy of dimensional tolerances and geometric tolerances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A tensioning and positioning milling method for special-shaped members of superhard materials, comprising the following steps in sequence:

[0069] The first step, nesting;

[0070] The component blank is a round bar of Φ120*170mm, and the blank is processed into two parts symmetrically from the middle left and right by the wire cutting process, which can maximize the use of materials.

[0071] The second step, rough machining: rough machining the components according to the requirements of the process drawings;

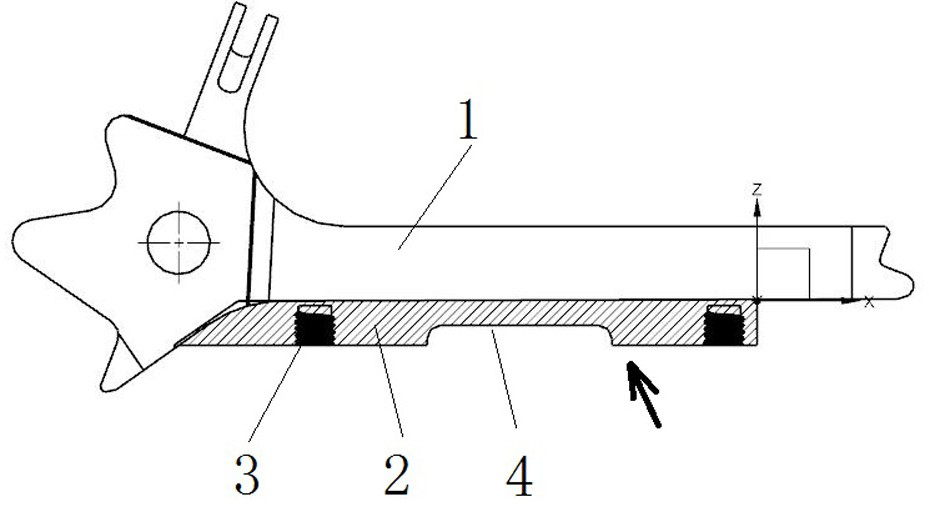

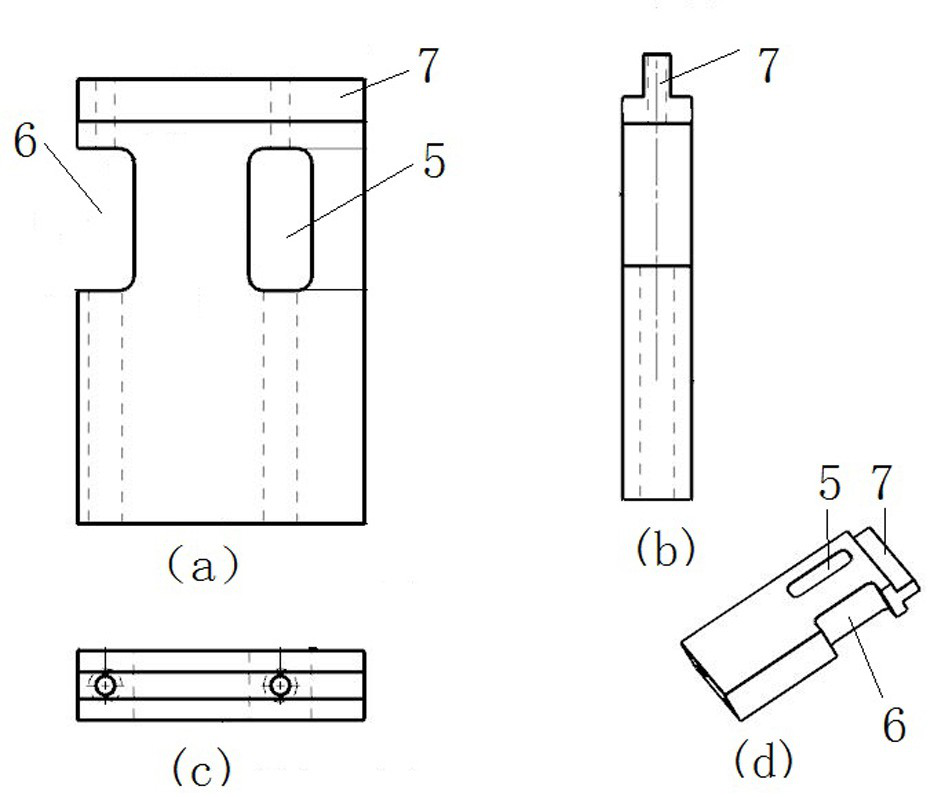

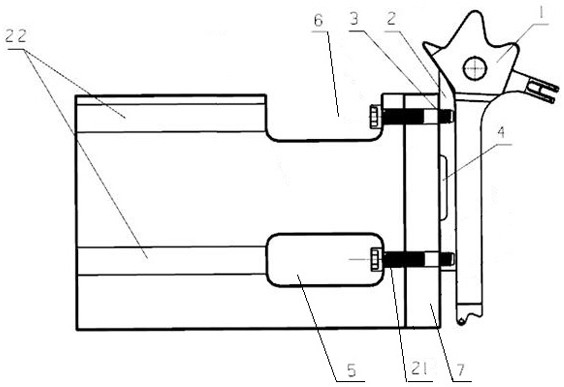

[0072] The processing program is compiled by software programming, and the special-shaped component 1 is rough-machined according to the requirements of the process drawings, and the shape is made according to the drawing, with a 3mm allowance on one side, and a margin of clamping process steps is reserved on the special-shaped component during rough machining.

[0073] The third step is to process the boss: make a step for the clamping process reserved on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com