Turbine assembly drill jig

A technology of turbine components and drilling jigs, which is applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problems of low processing efficiency and difficulty in guaranteeing the drilling accuracy of turbine hubs, etc., so as to improve production efficiency, avoid errors, and not The effect of lower pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

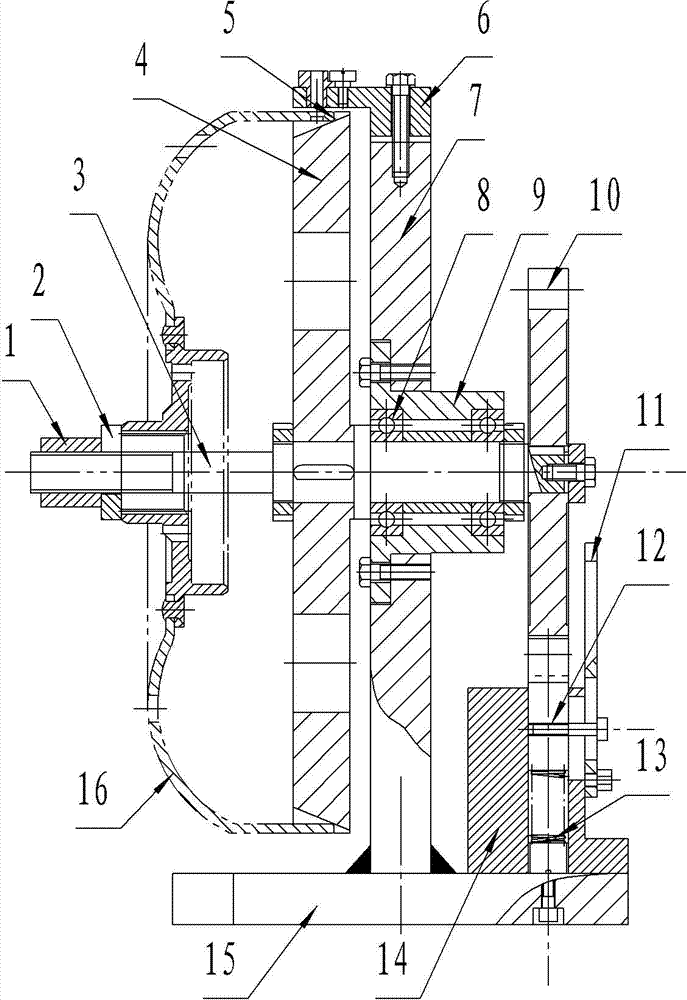

[0010] like figure 1 The shown turbine assembly drilling jig includes a support 7 vertically installed on the base 15, a rotating shaft 3 passes through the middle part of the support 7 horizontally through the bearing 8 and the bearing seat 9, and a Axle sleeve, rotating shaft 3 is equipped with a circular plate 4 for positioning the end face of the turbine hub 16 at the front part of the support 7, and the periphery of the circular plate 7 is provided with a groove 5 for positioning the end face of the turbine hub 16, and the support 7 The upper end is equipped with a curved plate 6 bent forward, the end surface of the turbine hub 16 is placed in the groove 5 of the circular plate 7, and is limited by the curved plate 6, the front end of the rotating shaft 3 passes through the shaft hole of the turbine hub 16 and passes through the nut 1 Fastene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com