Laser material increasing and decreasing combined manufacturing method and device

A technology of subtractive manufacturing and adding and subtracting materials, which is applied in the field of 3D printing, can solve problems such as processing limitations and compatibility issues, and achieve good compatibility, simple control, and improved forming accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

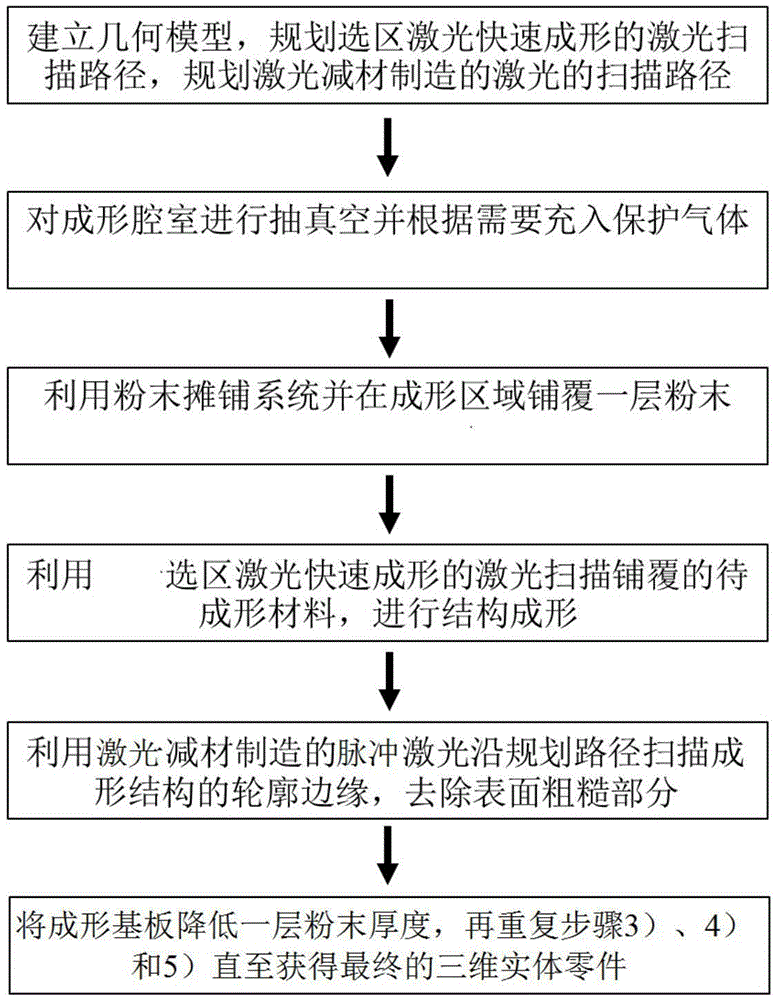

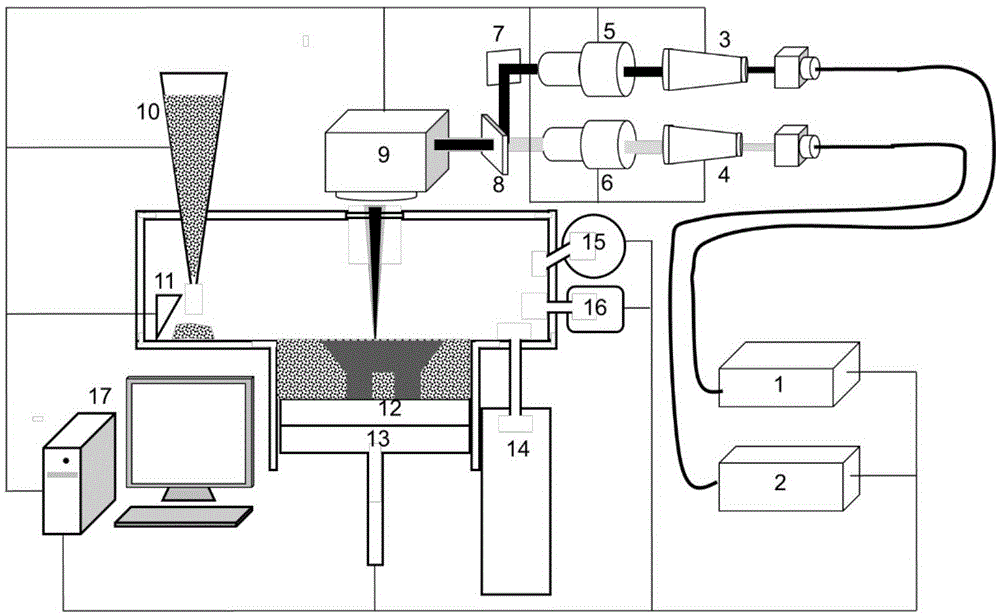

[0044] The following combination figure 1 and figure 2 , the present invention is described in detail by taking the composite manufacturing of titanium alloy based on selective laser rapid prototyping by laser addition and subtraction as an example. The selected titanium alloy powder is a nearly spherical powder with a particle size of 30-50 μm.

[0045] First, design the geometric model of the titanium alloy structure for forming, plan the scanning path of the laser for selective laser rapid prototyping, and plan the scanning path of the pulsed laser for laser subtractive manufacturing; then use the atmosphere control system to vacuumize the forming chamber and Fill the protective gas argon, and control the atmosphere during the forming process; use the powder feeder 10 to feed titanium alloy powder, and use the scraper 11 of the powder spreading system to spread a layer of titanium alloy with a thickness of 50-70 μm on the forming substrate powder; the laser beam emitted b...

Embodiment 2

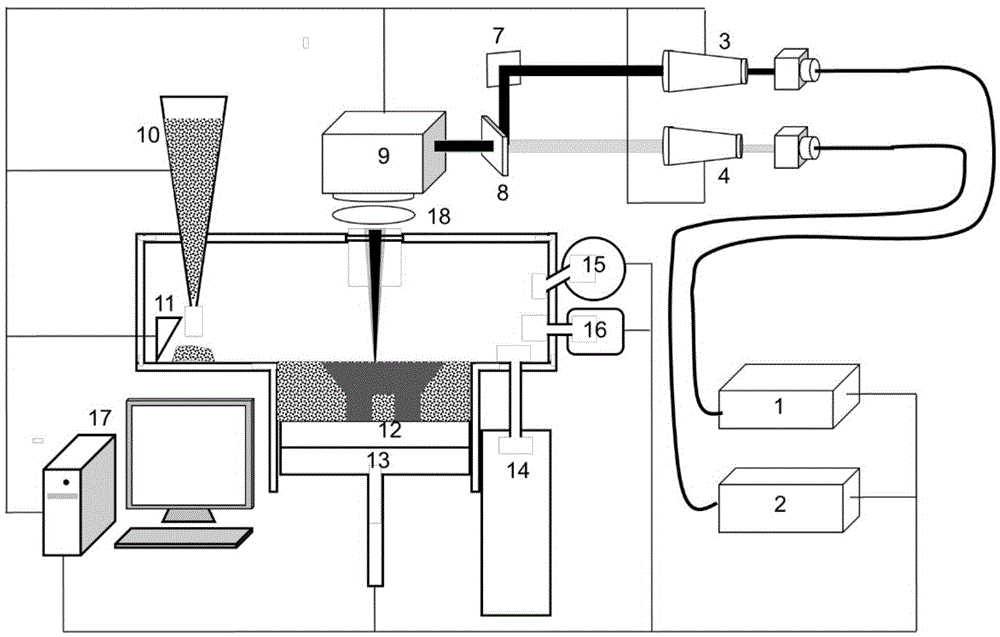

[0047] The following combination figure 1 and image 3 , with Al 2 o 3 The present invention is described in detail by taking multi-wavelength laser selective rapid prototyping of ceramics as an example. Selected Al 2 o 3 The ceramic powder is a nearly spherical powder with a particle size of 30-60 μm.

[0048] First, design the geometric model of the ceramic structure used for forming, plan the scanning path of the laser for selective laser rapid prototyping, and plan the scanning path of the pulsed laser for laser subtractive manufacturing; then, use the atmosphere control system to vacuumize the forming chamber And control the degree of vacuum in the forming cavity; Utilize powder feeder 10 to send into Al 2 o 3 Ceramic powder, using the scraper 11 of the powder spreading system to spread a layer of Al with a thickness of 50-70 μm on the forming substrate 2 o 3 Ceramic powder; the laser beam emitted by laser I1 for selective laser rapid prototyping and focused on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com