A three-in-one intelligent smt printing machine

A printing machine, three-in-one technology, applied in the field of three-in-one intelligent SMT printing machine, to achieve the effect of reducing labor costs and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

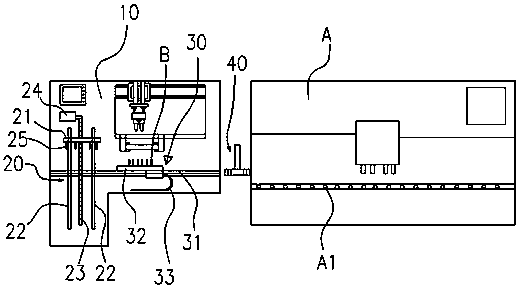

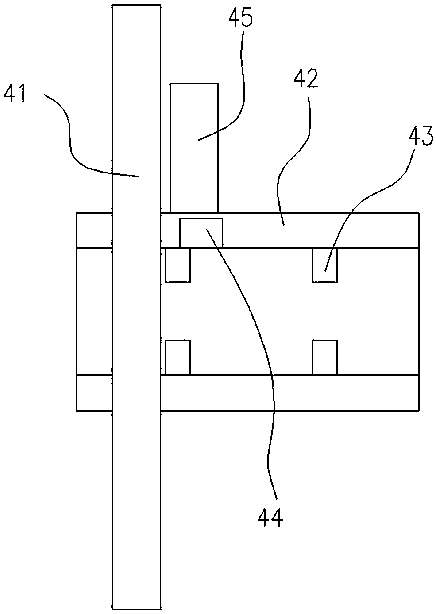

[0011] like Figure 1 to Figure 2 Shown is a preferred specific implementation example of the present invention, a three-in-one intelligent SMT printing machine, including a printing machine 10, a retrieving mechanism 20, a conveying mechanism 30, and a variable transmission position according to the track position of the placement machine The transplanting machine 40, wherein, the material taking mechanism 20, the conveying mechanism 30, and the transplanting machine 40 are arranged in the interior of the printing machine 10 in sequence, and after the material taking mechanism 20 obtains the workpiece, the material taking mechanism 20 passes through the The mechanism 30 transfers the workpiece to the conveying mechanism 30, and then the workpiece is conveyed to the corresponding position of the printing machine 10 by the conveying mechanism 30 for solder paste or glue printing operation, and then the workpiece is conveyed and transferred to the transplanting machine 40. The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com