Power control method based on cascaded multilevel ground overvoltage phase splitting system

A cascaded multi-level, over-power phase separation technology, applied in power lines, transportation and packaging, vehicle parts, etc., can solve the problems of production cut-off over-voltage, inconsistent voltage phase, closing surge over-current and other problems, reaching The effect of improving adaptability and avoiding transient processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

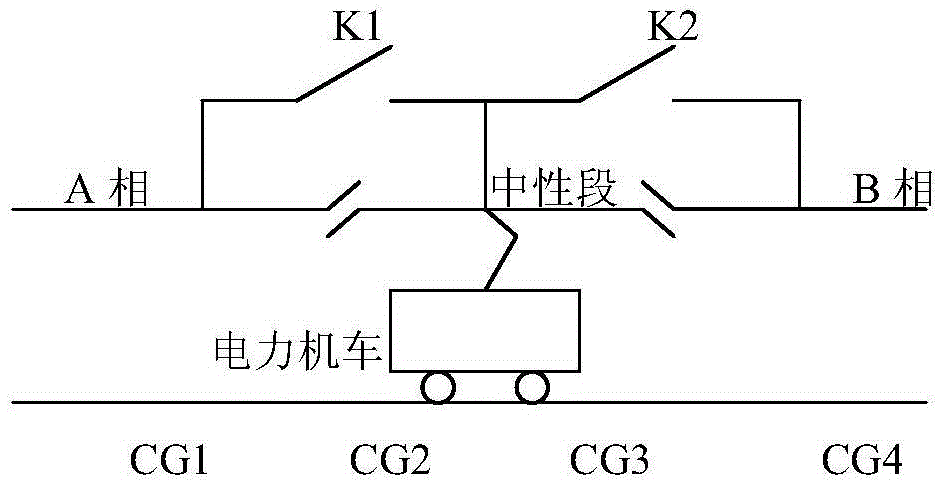

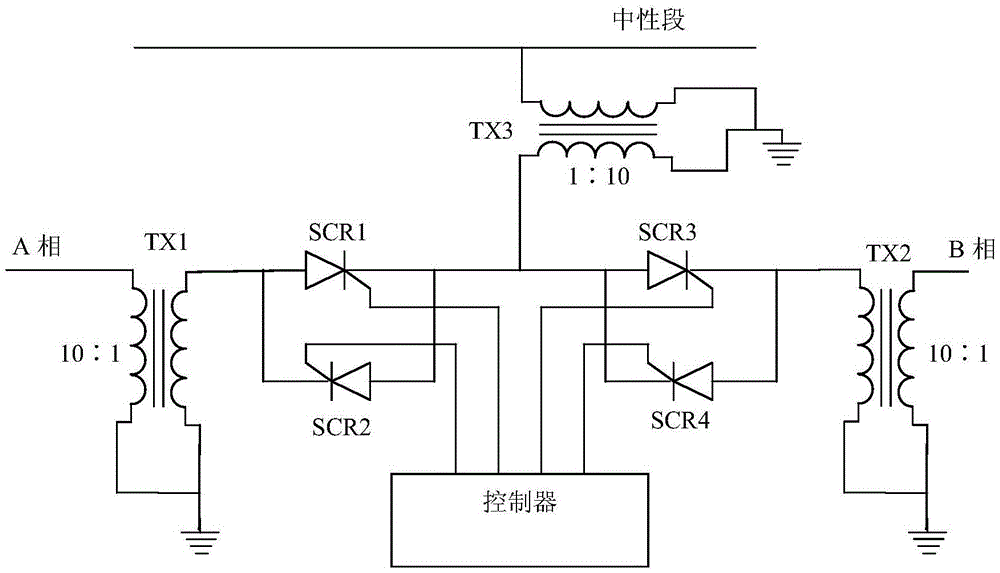

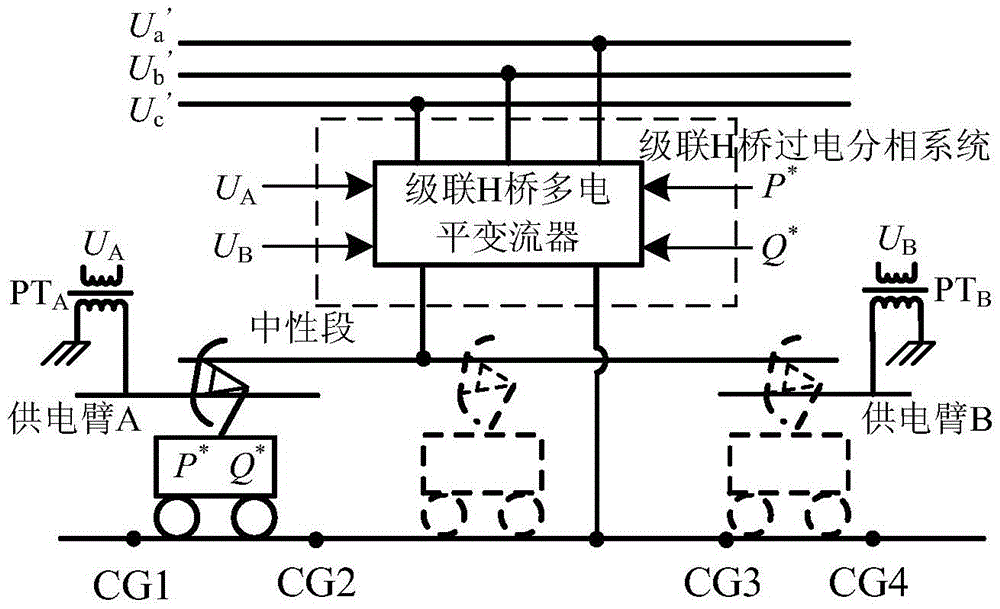

[0025] The locomotive position sensors CG1, CG2, CG3, CG4 for determining the position of the locomotive and the catenary voltage for measuring the catenary voltage phase are respectively connected between the phases A and B of the catenary power supply arm and the overcurrent phase splitting device Phase detection module PT A and PT BIn a system composed of an electric locomotive power real-time receiving device and a cascaded multi-level ground over-current phase-splitting device, such as image 3 As shown in the embodiment, the power control schematic diagram disclosed by the present invention is as follows Figure 4 As shown, its specific implementation is as follows:

[0026] 1. When the train runs from CG1 to CG4,

[0027] 1) When the train does not reach CG1, the reference active power and reference reactive power of the converter in the given corresponding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com