Low-floor vehicle elastic hinge device with adjustable stiffness and method for adjusting stiffness

A low-floor car, elastic hinge technology, which is applied in transportation and packaging, railway car body parts, railway couplings, etc., can solve the problems that the elastic hinge device cannot automatically adjust its own rigidity, cannot provide safety guarantee, etc., and achieves a simple structure. , The effect of convenient disassembly and assembly, convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

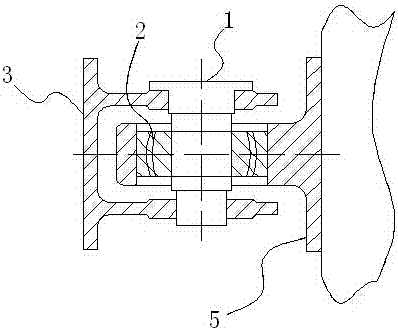

[0039] Embodiment 1: as Figure 1 to Figure 3 As shown, an elastic hinge device for low-floor vehicles with adjustable stiffness includes a center pin 1, a ball joint pair 2 and a rigid hook 3 fixedly arranged on a carriage. The center pin 1 and the rigid hook 3 Fixedly connected as a whole, the elastic hinge device of the low-floor vehicle also includes a middle plate 4, a front support 5 and a rear support 6 respectively arranged on opposite sides of the middle plate 4, the front support 5, the rear support 6 and the middle plate 4 are integrally connected by M16 bolts, and the rubber support body 1 7 and the rubber support body 2 8 that support the middle plate 4 in the air by connecting with the opposite sides of the middle plate 4 are arranged on the The rubber stop one 9 and the rubber stop two 10 on the opposite sides of the rear support 6 cooperate with the rubber stop one 9 and the rubber stop two 10 and are respectively fixedly arranged on the rubber support body one...

Embodiment 2

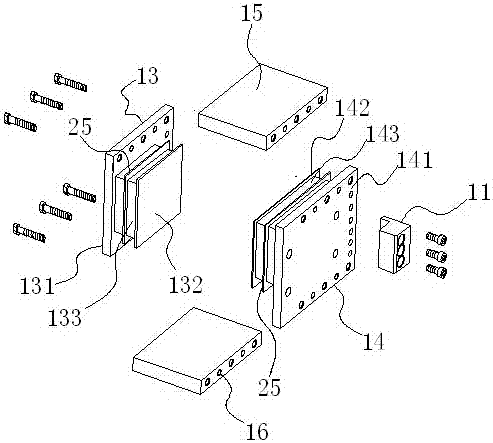

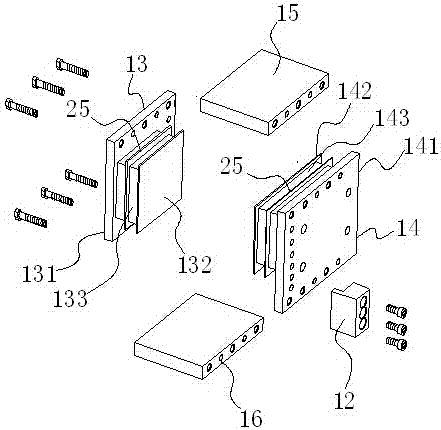

[0050] Embodiment 2: as Figure 10 to Figure 12 As shown, compared with Embodiment 1, the difference is: the front elastic rubber body 133 of the rubber support body one 7, the rear elastic rubber body 143 of the rubber support body one 7, and the front elastic rubber body 143 of the rubber support body two 8 The rear elastic rubber body 143 of the body 133 and the rubber support body 2 8 is all in a longitudinally pre-compressed state. The front and rear elastic rubber bodies of rubber support body 1 7 and rubber support body 2 8 are pre-compressed to a certain amount during assembly, so that the device only bears compressive stress during the operation of the train, which satisfies the The use requirements greatly improve the service life of the front and rear elastic rubber bodies. The front elastic rubber body and the rear elastic rubber body are individually pre-compressed during assemblyL 3 , assuming that the longitudinal stiffness of the front elastic rubber body and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com