A kind of production device and production method of basalt fiber

A basalt fiber and production device technology, applied in glass manufacturing equipment, feeding troughs, manufacturing tools, etc., can solve the problems of inability to achieve continuous operation and large-scale production, affecting fiber continuity operations, poor thermal conductivity of basalt, etc. Improve chemical unevenness, improve temperature unevenness, and facilitate disassembly and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

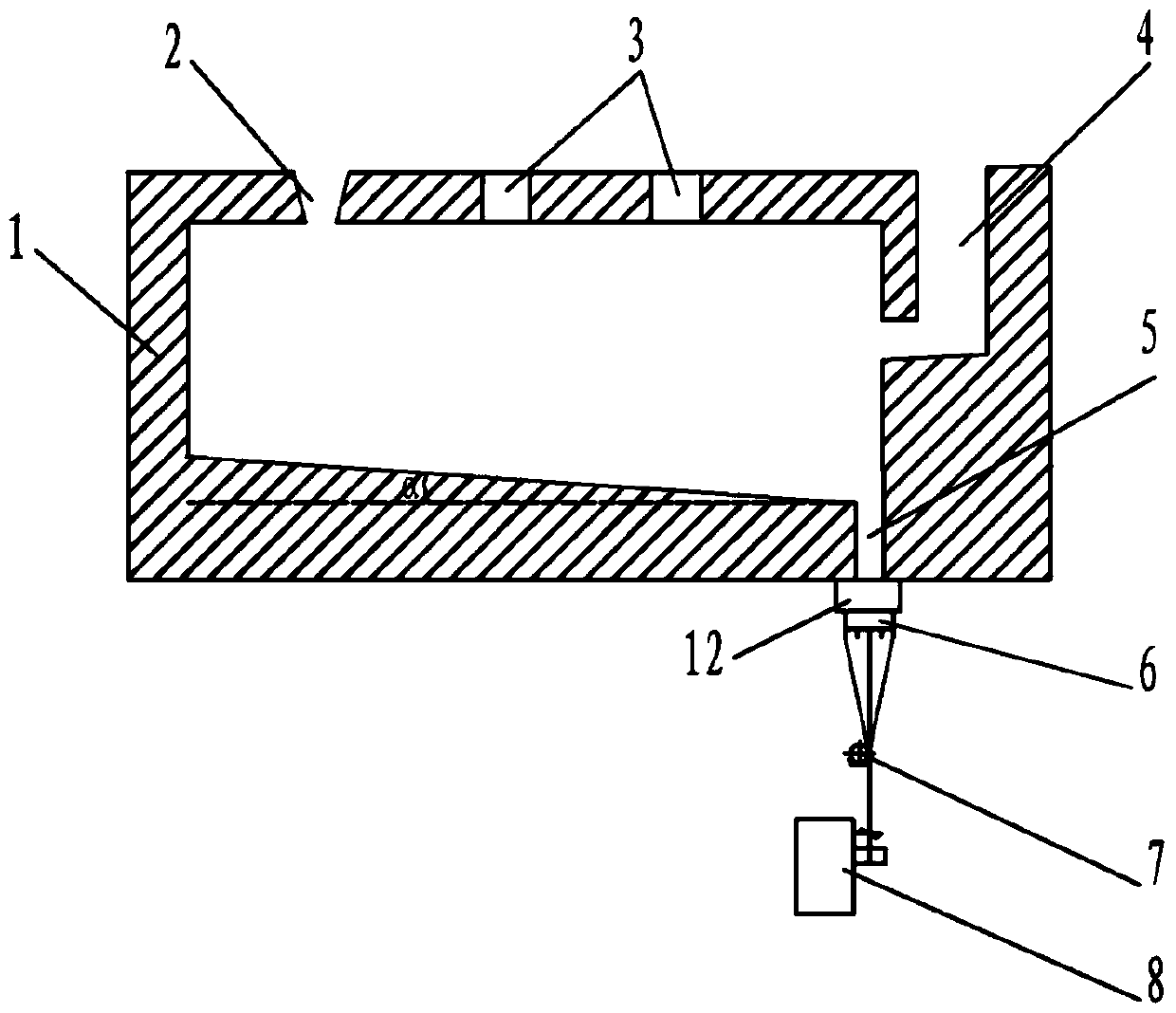

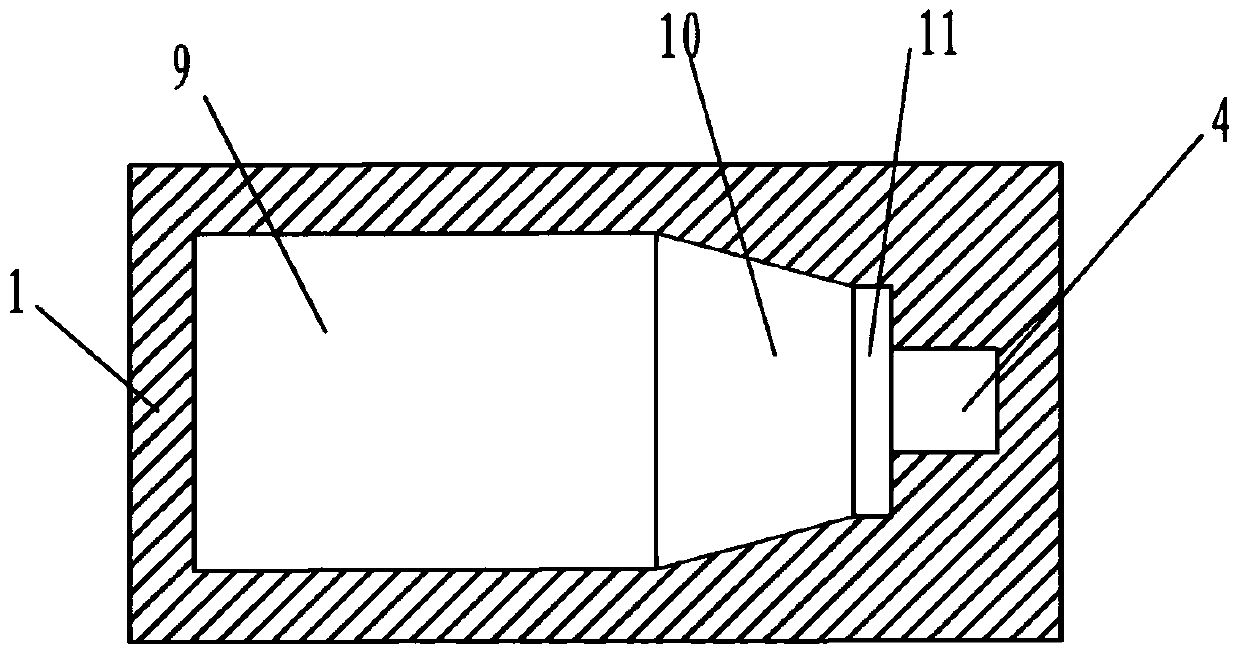

[0032] The production device of the basalt fiber used in the present invention is as figure 1 and figure 2 As shown, it includes an ore melting furnace 1 and a wire drawing machine 8. The top of the furnace cavity of the ore melting furnace 1 is provided with a feed port 2 and a burner 3 in sequence from left to right. It includes a melting zone 9, a clarification zone 10 and a discharge flow channel 5. The width of the clarification zone 10 gradually narrows from the melting zone 9 to the discharge flow channel 5, and a detachable platinum plate is installed under the discharge flow channel. Channel 12; the right side wall of the furnace cavity is provided with a smoke exhaust channel 4, so as to discharge the waste gas generated in the furnace; a discharge port 11 is provided between the discharge channel and the detachable platinum channel; A bushing 6 is installed under the disassembled platinum channel 12, and an oiling cluster 7 and a wire drawing machine 8 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com