A kind of ultra-flat glaze frit and its method of manufacturing super crystal

A super crystal and frit technology, applied in the field of super crystal preparation, can solve problems such as making breakthroughs, achieve high initial melting point, overcome easy scratches, and ingenious structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

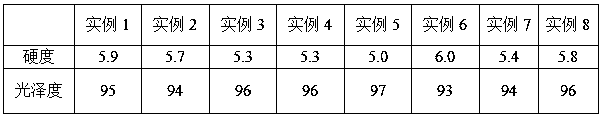

Examples

Embodiment 1

[0027] An ultra-flat glaze frit is prepared from the following raw materials in parts by mass: potassium feldspar: 53 parts, wollastonite: 25 parts, calcined talc: 15 parts, and barium carbonate: 7 parts.

[0028] The firing method of frit is:

[0029] (1) Weigh the raw materials and mix them evenly;

[0030] (2) Melt at a temperature of 1500-1600°C and keep warm for 2-3 hours;

[0031] (3) Water quenching and drying to obtain frit with high initial melting point and low expansion coefficient.

[0032] A super-flat glaze, which is made of the above-mentioned frit and raw material in a ratio of frit:raw material=80:100.

[0033] The composition of the raw material is: 45 parts of quartz, 8 parts of potassium feldspar, 10 parts of wollastonite, 7 parts of burnt talc, 10 parts of barium carbonate, 10 parts of zinc oxide, 3 parts of strontium carbonate, 4 parts of clay, and 3 parts of burnt soil , in parts by mass.

[0034] A preparation method of super crystal, the steps are ...

Embodiment 2

[0037] An ultra-flat glaze frit is prepared from the following raw materials in parts by mass: 60 parts of potassium feldspar, 18 parts of wollastonite, 15 parts of calcined talc, and 7 parts of barium carbonate; the firing method is as in Example 1 .

[0038] A super-flat glaze, which is made of the above-mentioned frit and raw material in a ratio of frit:raw material=80:100.

[0039] The composition of the raw material is: 45 parts of quartz, 8 parts of potassium feldspar, 10 parts of wollastonite, 7 parts of burnt talc, 10 parts of barium carbonate, 10 parts of zinc oxide, 3 parts of strontium carbonate, 4 parts of clay, and 3 parts of burnt soil , in parts by mass.

[0040] A preparation method of super crystal, the steps are as follows:

[0041] Apply a layer of bottom glaze on the biscuit, adopt the glaze pouring process, and the glaze is 400g; then apply a layer of the above-mentioned super flat glaze on the green body with the bottom glaze, the glaze is 1050g, and it...

Embodiment 3

[0043] An ultra-flat glaze frit, prepared from the following raw materials by mass: potassium feldspar: 65 parts, wollastonite: 13 parts, calcined talc: 15 parts, barium carbonate: 7 parts; the firing method is as described in the examples 1.

[0044] A super-flat glaze, which is made of the above-mentioned frit and raw material in a ratio of frit:raw material=80:100

[0045] The composition of the raw meal is:

[0046] 45 parts of quartz, 8 parts of potassium feldspar, 10 parts of wollastonite, 7 parts of burnt talc, 10 parts of barium carbonate, 10 parts of zinc oxide, 3 parts of strontium carbonate, 4 parts of clay, and 3 parts of burnt earth, in parts by mass. A preparation method of super crystal, the steps are as follows:

[0047] Apply a layer of bottom glaze on the green body of 890×890mm, adopt the glaze pouring process, the glaze is 400g, and then apply a layer of the above-mentioned super flat glaze on the green body with the bottom glaze, the glaze is 1050g, 1180...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com