Building joint of modular house combining and splicing structure

A technology for integrating houses and buildings, applied in the direction of buildings and building structures, etc., can solve the problems of not achieving the stability of the building structure, different node shapes, thicknesses, and incompatibility, and achieve simple structure, good structural versatility, The effect of easy loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

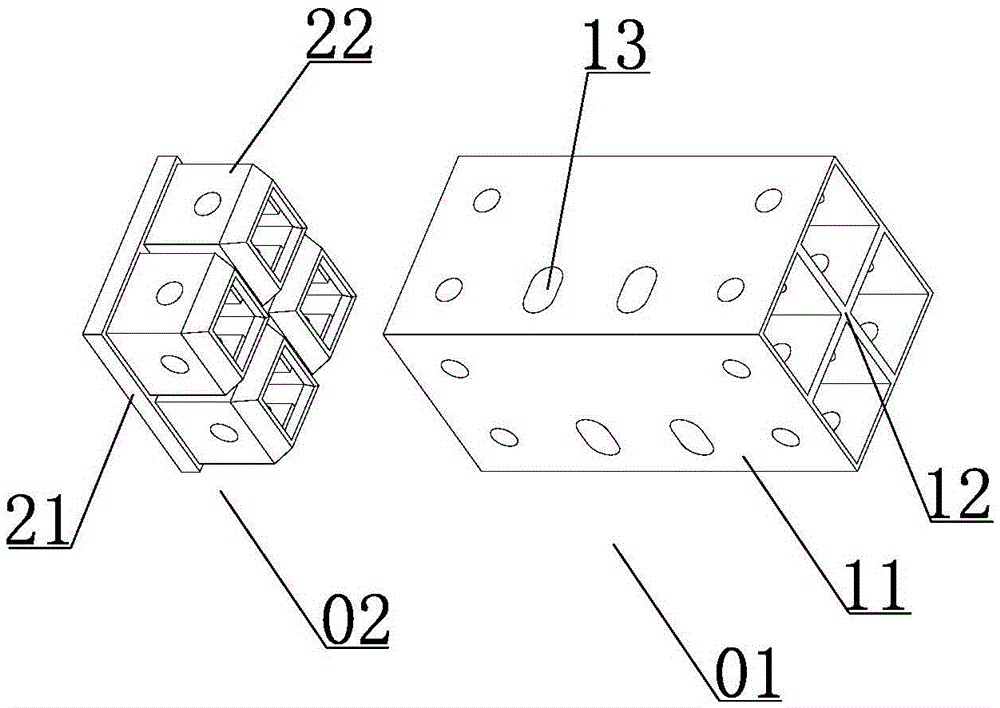

[0019] Such as figure 1 As shown, a building node of an integrated house combination splicing structure includes a corner piece 01 and a connecting piece 02 connected with the corner piece 01 . The corner piece 01 includes a square pipe column 11 and a cross-shaped partition 12 inside the square pipe column 11 that divides the inside of the square pipe column 11 into a cross grid. A plurality of bolt holes 13 are respectively arranged on the four surfaces of the square pipe column 11 and the partition plate. The connector 02 includes a fixed plate 21 with the same shape and size as the bottom of the square column 11 and a tapered standpipe 22 that can be inserted into the square column 11 and fixed tightly on the fixed plate 21 . There are four tapered standpipes on the fixed plate 21 and they are distributed on the fixed plate 21 in a square shape. The pipe column and the partition are fixed by welding with the same material and equal strength or integrally formed, and the ...

Embodiment 2

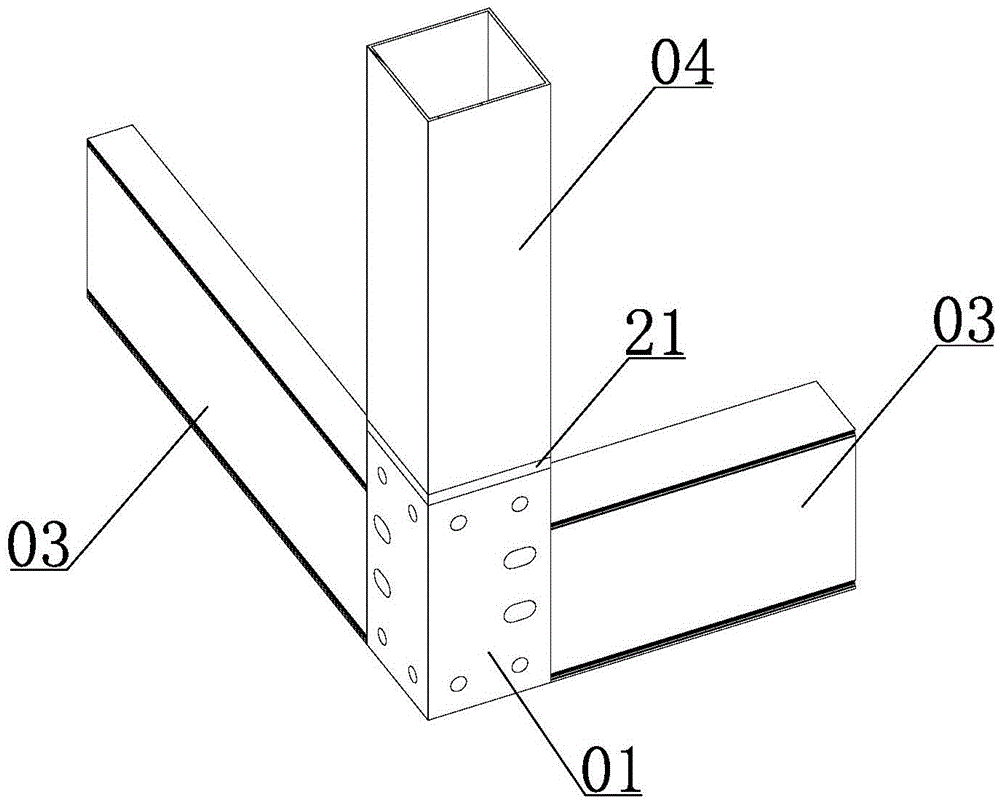

[0021] Such as figure 2 As shown, without changing Embodiment 1, a node is connected to a building steel column 04 and two building steel beams 03 are connected.

[0022] The four tapered risers 22 on a connecting piece 02 are aligned with the corner piece 01, and the surroundings are fixed by bolts, and then the building steel column 04 is welded vertically on the fixing plate 21, and finally horizontal on the side panel of the square column 11. Just weld the construction steel beam 03.

Embodiment 3

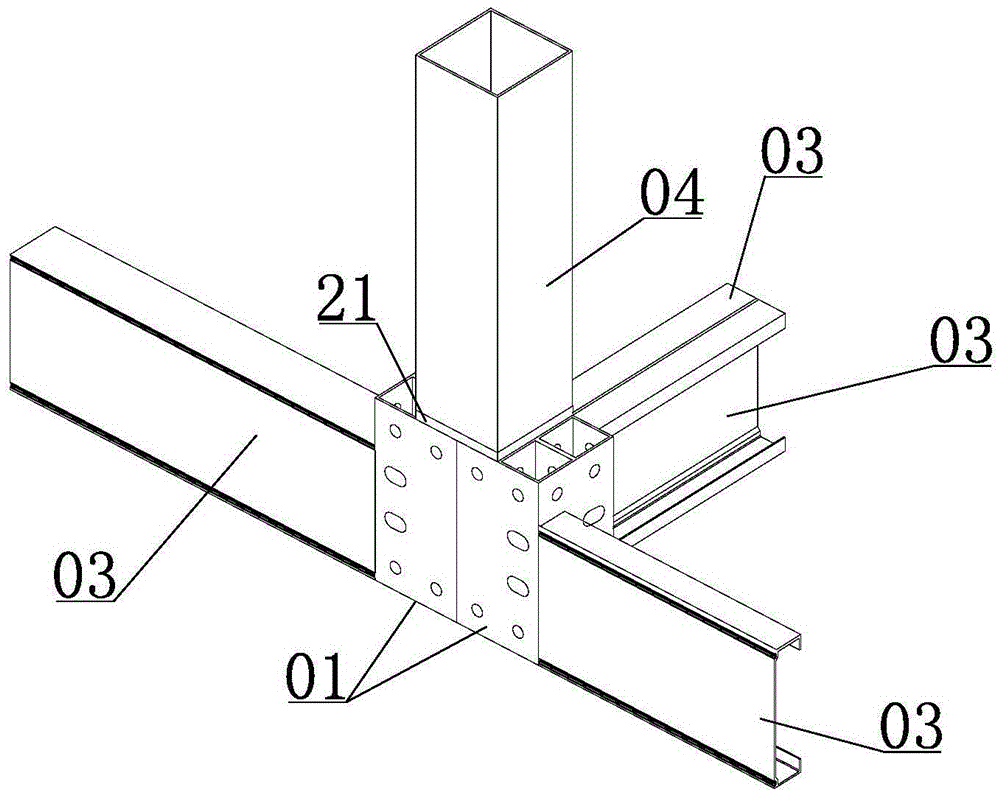

[0024] Such as image 3 As shown, under the condition of not changing the embodiment 1, two nodes are connected with one building steel column 04 and four building steel beams 03 are connected.

[0025] The four tapered risers 22 on one connecting piece 02 are respectively butted with the grids on the two corner pieces 01, and then the building steel columns 04 are vertically welded on the fixing plate 21, and the last four building steel beams 03 are respectively welded on the two corner pieces 01. On the side panel of a corner fitting 01, there are two construction steel beams 03 in the same direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com