Composite control valve group, control loop and hoisting translation control method of crane

A compound control and valve group technology, which is applied in the direction of mechanical equipment, transportation and packaging, load hanging components, etc., can solve the problems of low compound operation level of operators, uneven load of a single crane, rollover, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

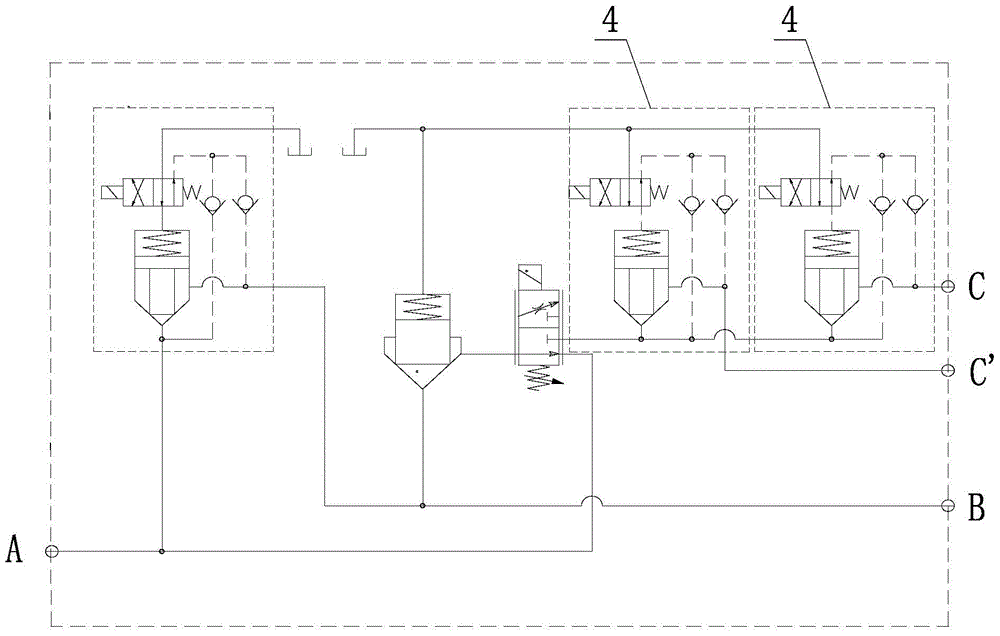

[0047] like figure 1 or figure 2 As shown, the present invention first provides a compound control valve group, the compound control valve group has a first oil port A, a second oil port B and an oil branch port C, and the first oil port A and the second oil port B are An oil inlet on-off valve 1 is provided in the first internal oil circuit L1 connected to each other, and an oil return check valve 2, The proportional flow valve 3 and the oil separation on-off valve 4, the forward port of the oil return check valve 2 is hydraulically connected to the second oil port B, and the reverse port is hydraulically connected to the inlet port of the proportional flow valve 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com