Bar material peeling method capable of accurately breaking materials

A bar material cutting technology, applied in the field of bar material peeling, can solve the problems of inability to cut the bar material, fail to ensure the consistency of the bar material, waste manpower and material resources, etc., and achieve the goal of ensuring production efficiency, facilitating the processing process, and saving manpower and material resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

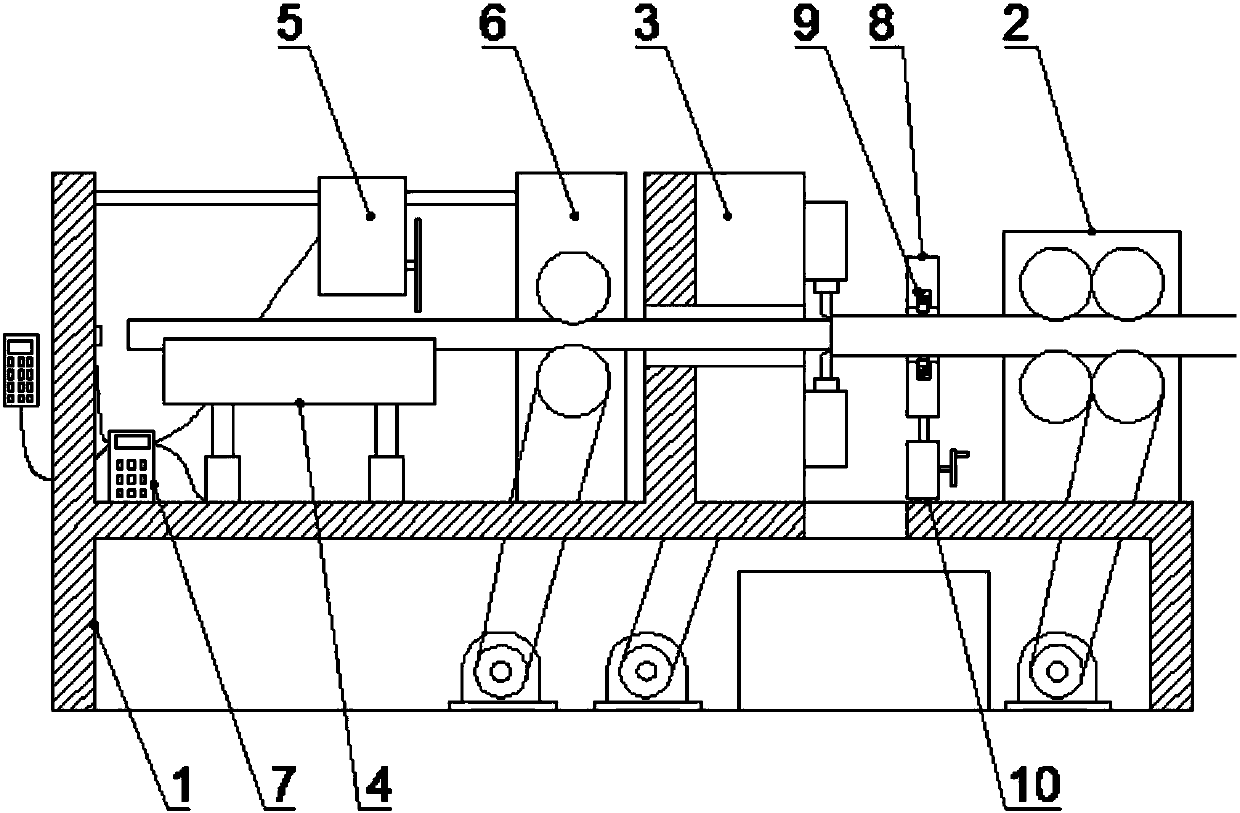

[0040] Such as figure 1 The shown bar stripping method capable of accurate cutting off includes a frame 1 and a feeding support mechanism 2 installed on the frame 1, a positioning mechanism, a stripping mechanism 3 and an automatic cutting mechanism, specifically including the following steps: Step 1: Prepare production equipment, a feeding support mechanism 2 is arranged on one side of the frame 1, and a positioning mechanism, a peeling mechanism 3 and an automatic material cutting mechanism are sequentially arranged on the frame 1; the automatic material cutting mechanism Including a lifting platform 4, a cutting mechanism 5, a cutting feed mechanism 6 and a control mechanism 7, the lifting platform 4 is arranged on the frame 1, a cutting mechanism 5 is arranged above the lifting platform 4, and a cutting mechanism 5 is arranged on the cutting mechanism 5 A control mechanism 7 for determining the cutting length is provided, and a cutting feeding mechanism 6 is arranged on on...

Embodiment 2

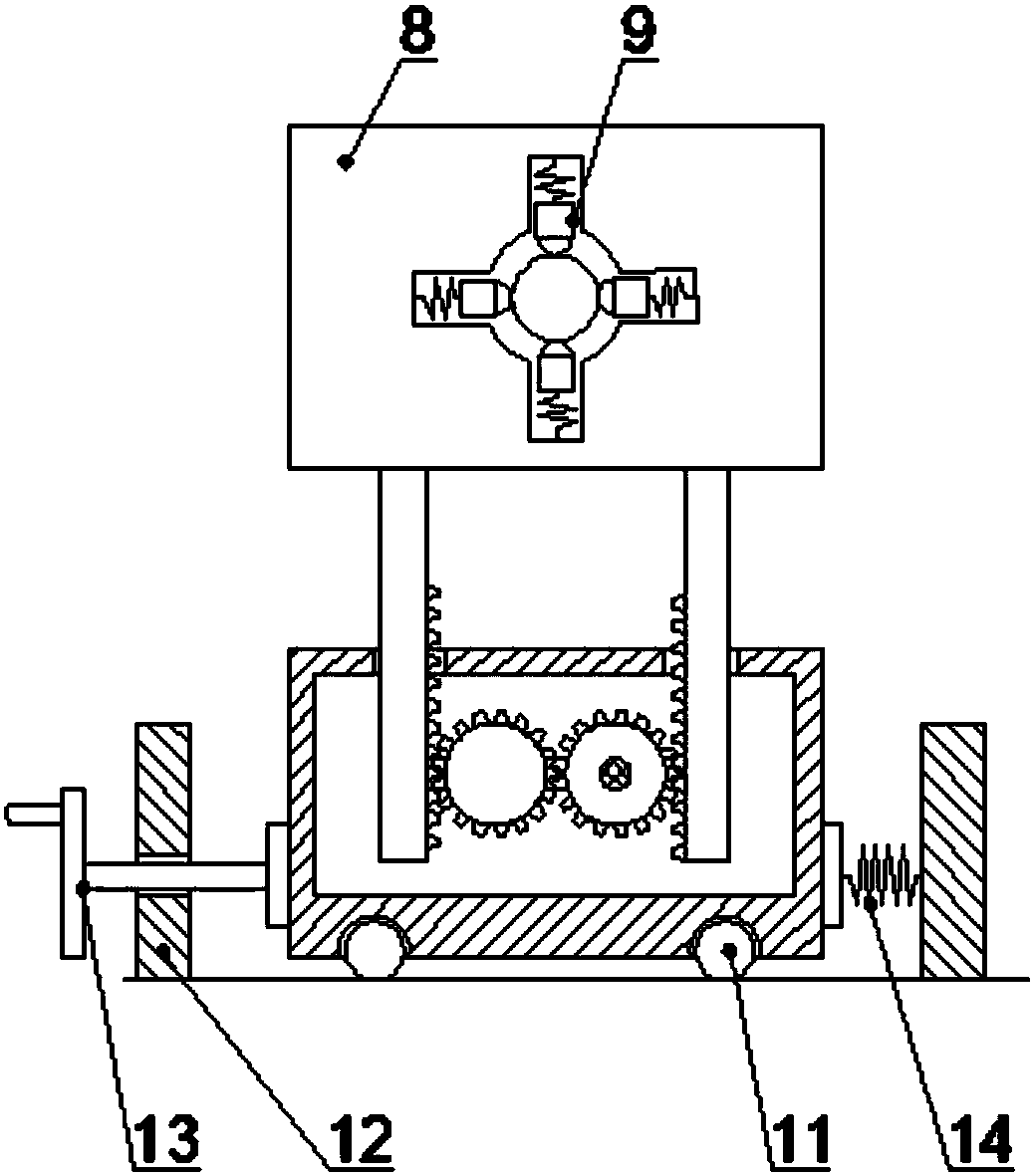

[0042] Such as figure 2 The shown bar stripping method capable of accurate cutting off includes a frame 1 and a feeding support mechanism 2 installed on the frame 1, a positioning mechanism, a stripping mechanism 3 and an automatic cutting mechanism, specifically including the following steps: Step 1: Prepare production equipment, a feeding support mechanism 2 is arranged on one side of the frame 1, and a positioning mechanism, a peeling mechanism 3 and an automatic material cutting mechanism are sequentially arranged on the frame 1; the automatic material cutting mechanism Including a lifting platform 4, a cutting mechanism 5, a cutting feed mechanism 6 and a control mechanism 7, the lifting platform 4 is arranged on the frame 1, a cutting mechanism 5 is arranged above the lifting platform 4, and a cutting mechanism 5 is arranged on the cutting mechanism 5 A control mechanism 7 for determining the cutting length is provided, and a cutting feeding mechanism 6 is arranged on o...

Embodiment 3

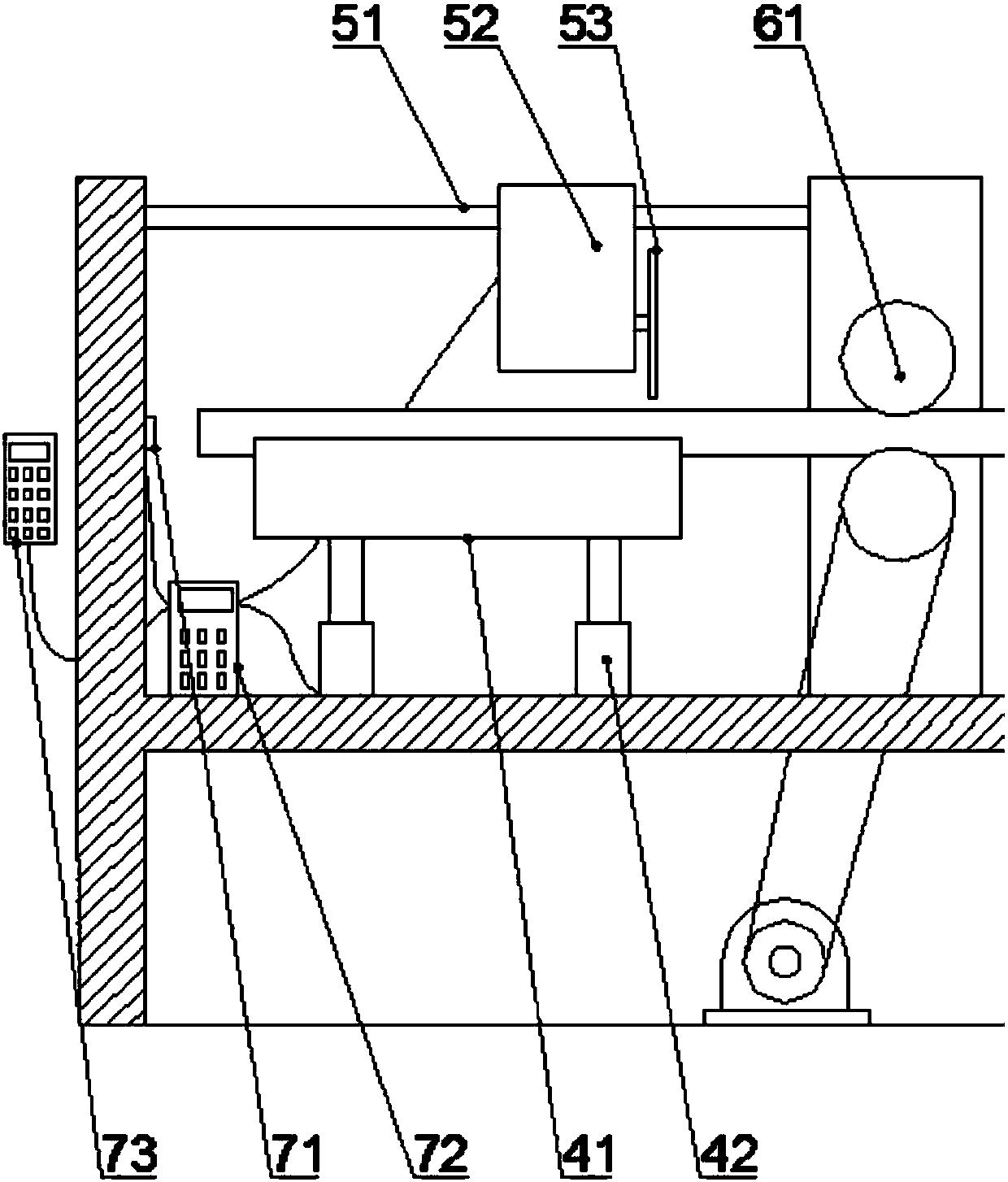

[0046] Such as image 3 The shown bar stripping method capable of accurate cutting off includes a frame 1 and a feeding support mechanism 2 installed on the frame 1, a positioning mechanism, a stripping mechanism 3 and an automatic cutting mechanism, specifically including the following steps: Step 1: Prepare production equipment, a feeding support mechanism 2 is arranged on one side of the frame 1, and a positioning mechanism, a peeling mechanism 3 and an automatic material cutting mechanism are sequentially arranged on the frame 1; the automatic material cutting mechanism Including a lifting platform 4, a cutting mechanism 5, a cutting feed mechanism 6 and a control mechanism 7, the lifting platform 4 is arranged on the frame 1, a cutting mechanism 5 is arranged above the lifting platform 4, and a cutting mechanism 5 is arranged on the cutting mechanism 5 A control mechanism 7 for determining the cutting length is provided, and a cutting feeding mechanism 6 is arranged on on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com