Touch panel and manufacturing method thereof

A technology of touch panel and manufacturing method, which is applied in the directions of instruments, computing, electrical digital data processing, etc., can solve the problems of high production cost of capacitive touch panel, achieve the goal of reducing production cost and production time, and simplifying the number of process steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

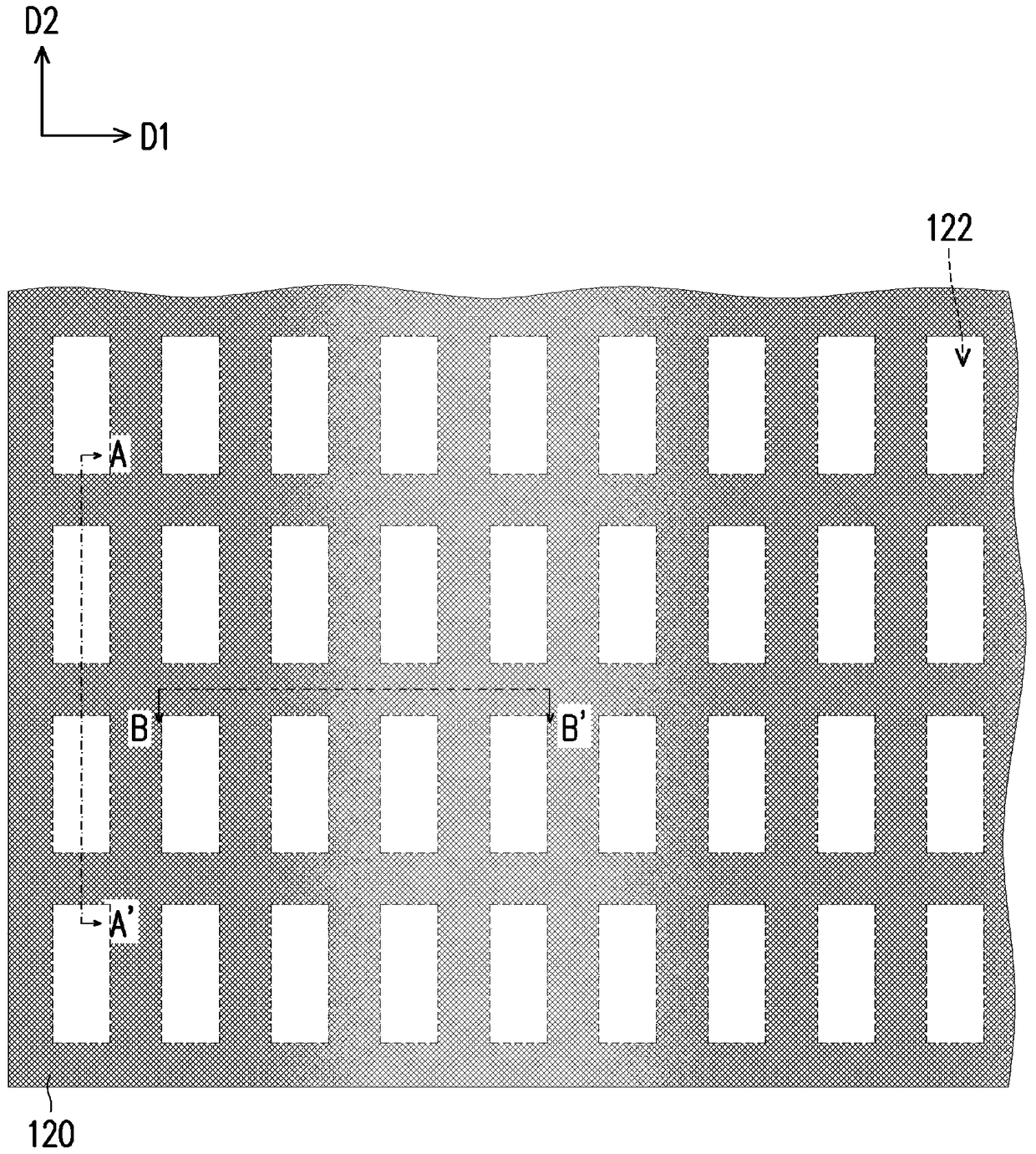

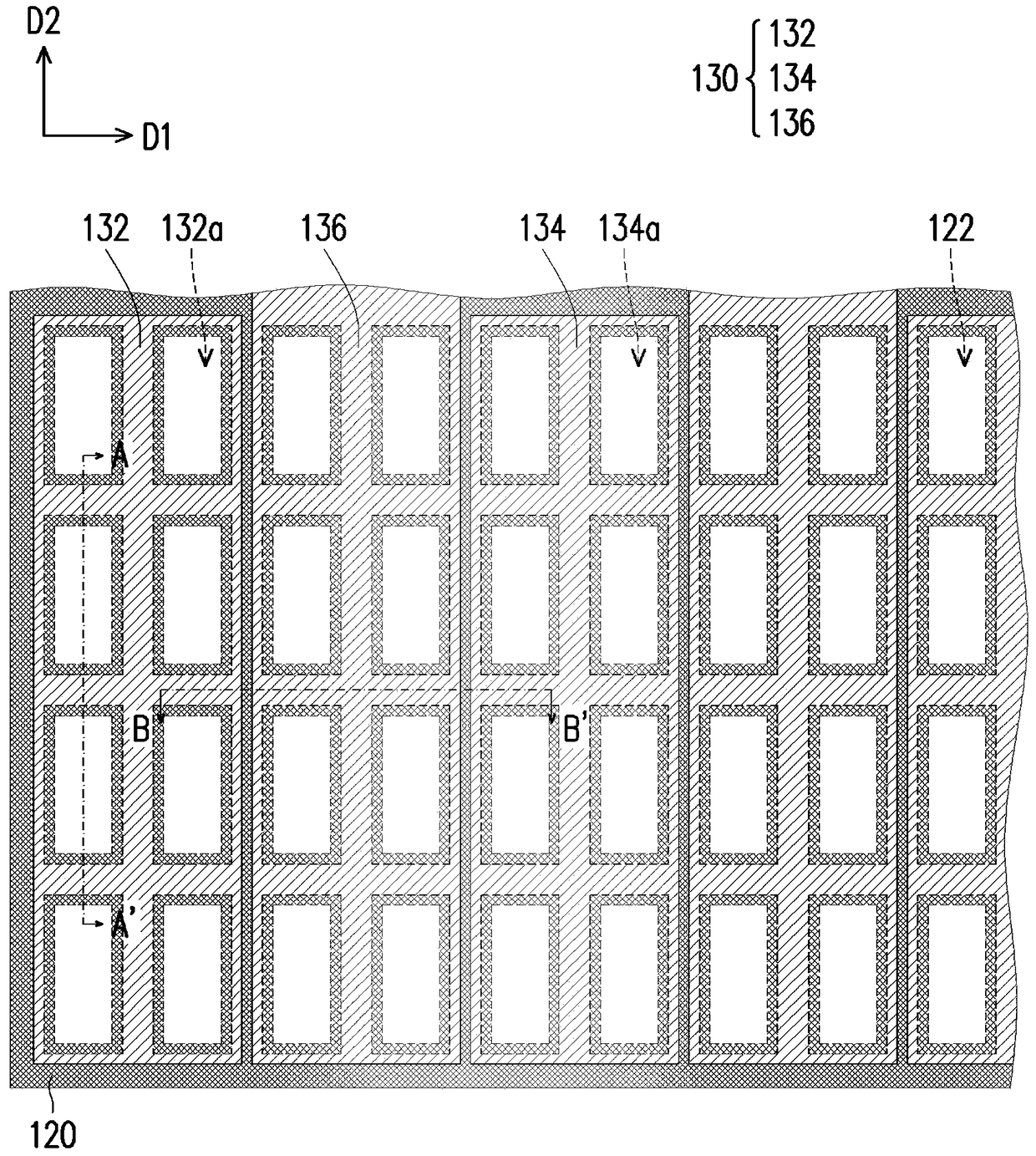

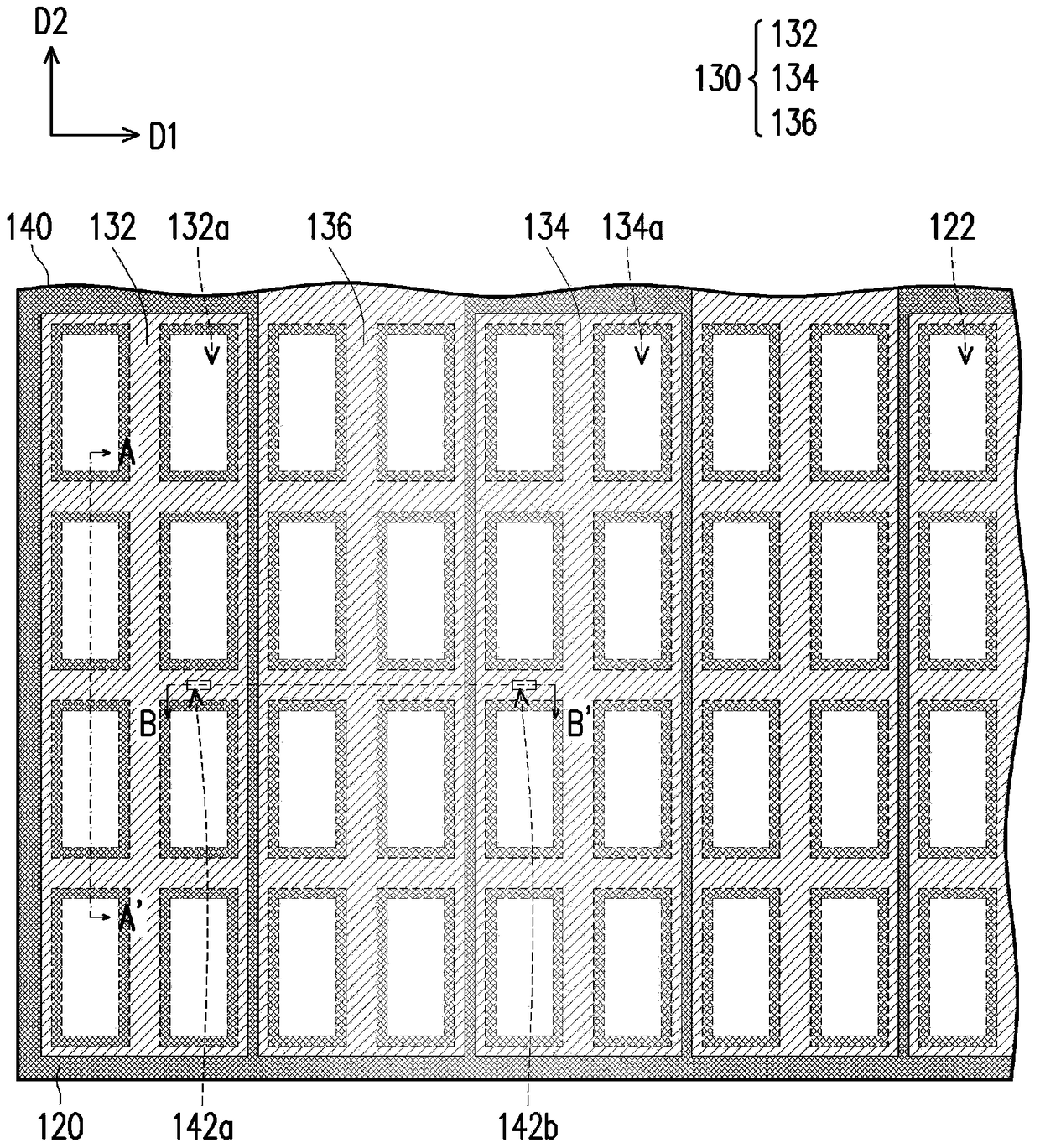

[0055] Figure 1A to Figure 1F It is a partial top view schematic diagram of a manufacturing method of a touch panel according to an embodiment of the present invention, Figure 2A to Figure 2F respectively along Figure 1A to Figure 1F The cross-sectional schematic diagram of the section line I-I', Figure 3A to Figure 3F respectively along Figure 1A to Figure 1F The cross-sectional schematic diagram of the section line II-II'. Figure 4A for Figure 1F A scaled-down schematic diagram of the touch panel, where Figure 1F corresponds to Figure 4A in area A, but Figure 4A Only the sensing layer and peripheral circuits electrically connected to the sensing layer are shown in FIG. Figure 4B for Figure 4A sectional schematic diagram. Please also refer to Figure 1A , Figure 1B , Figure 2A , Figure 2B , Figure 3A as well as Figure 3B Firstly, the sensing layer 130 is formed on the first substrate 110 . In this example, if Figure 1A , Figure 2A as well as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com