Isolated and connected combination switch

A combination switch and grounding switch technology, applied in the direction of electric switches, air switch components, electrical components, etc., can solve the problems of increasing gas leakage, shortening the service life of equipment, increasing water ingress and leakage, and reducing radial force Effect on airtightness, avoidance of triboelectric discharge phenomenon, and effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

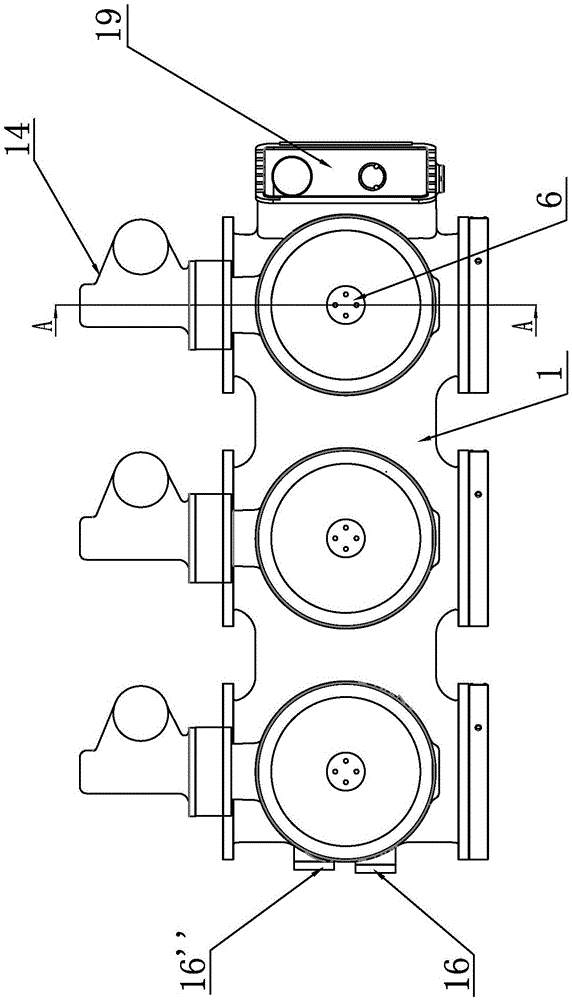

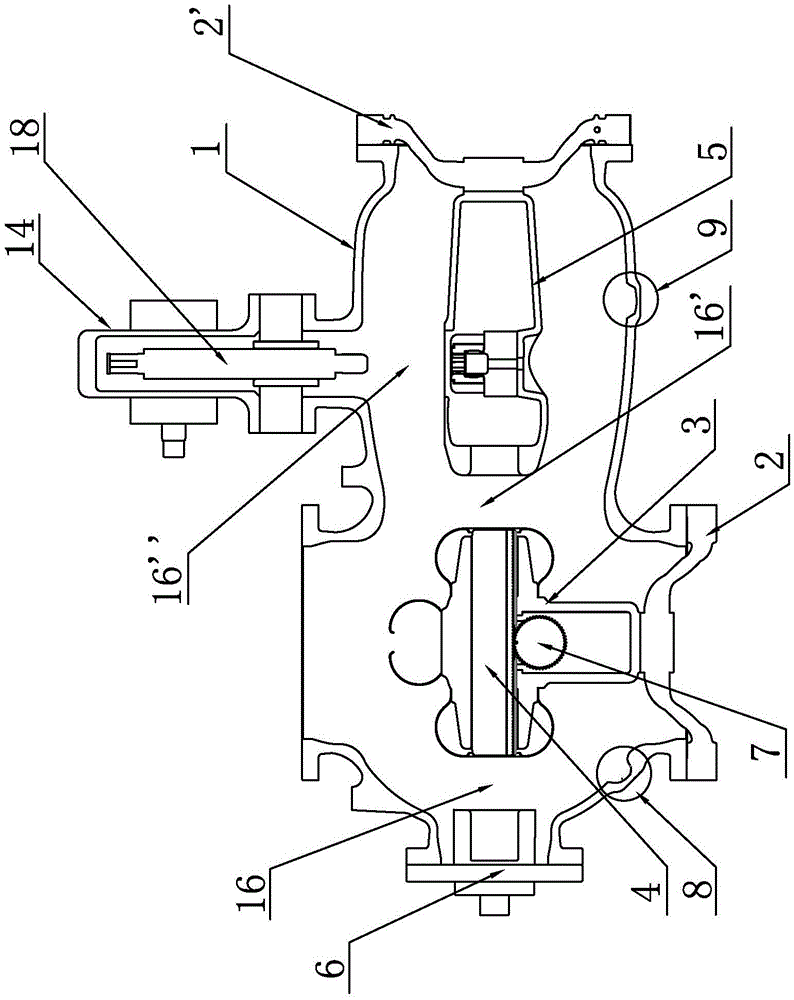

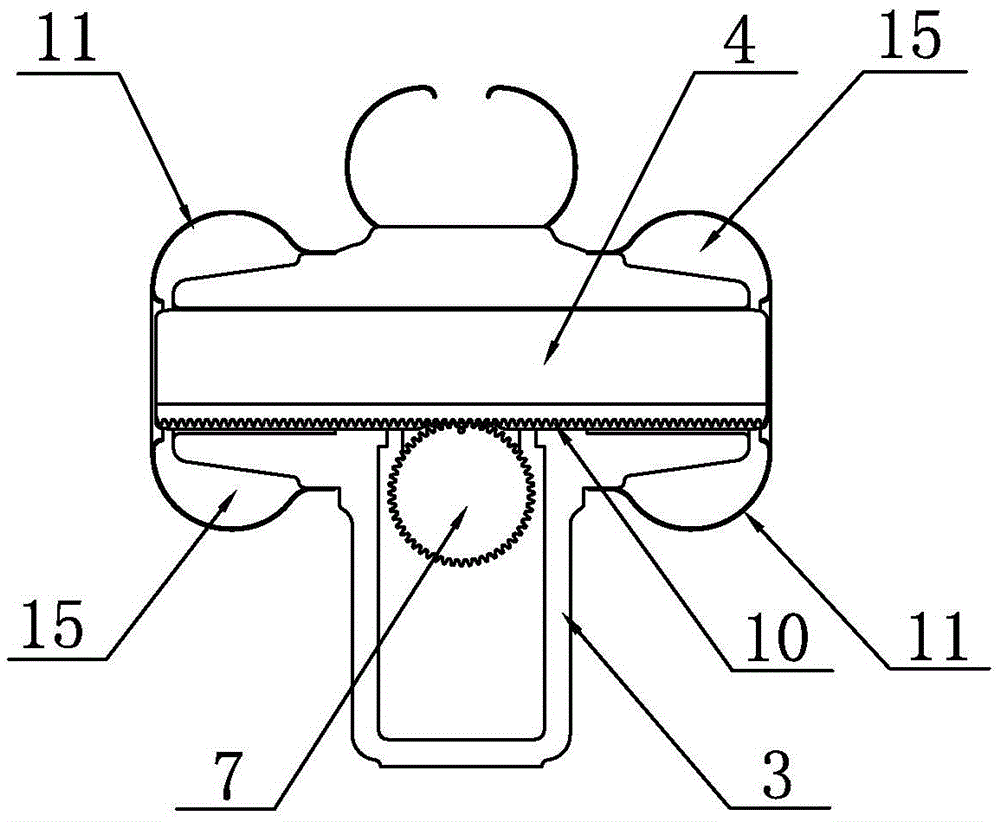

[0020] Such as figure 1 , figure 2 As shown, the isolating combination switch of the present invention includes a housing 1 , a first contact seat 3 , a first conductive rod 4 , a static end part 5 of an isolating switch and a static end part 6 of a grounding switch. The casing 1 is placed in the horizontal direction, and a first cavity is opened inside the casing 1. The grounding switch static end part 6 is installed at the opening of the front end of the casing 1, and the second pot insulator 2 is installed at the opening of the rear end of the casing 1. ', the first cavity inside the housing 1 is provided with a disconnector static end part 5, and the disconnector static end part 5 is fixedly connected with the second pot insulator 2', such as Figure 4 As shown, the static end part 5 of the isolating switch includes a contact seat 12 of the isolating switch and a contact seat 13 of the quick earthing switch. The hole 17, the through hole 17 is located directly above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com