Integrally formed embedded electrode component with inner umbrella skirt and outer shell

A technology of embedded pole and pole components, which is applied in the direction of electrical components, high-voltage air circuit breakers, electric switches, etc., can solve the problems of increasing the difficulty of demolding and the inability to demould, achieve small space, good connection strength, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

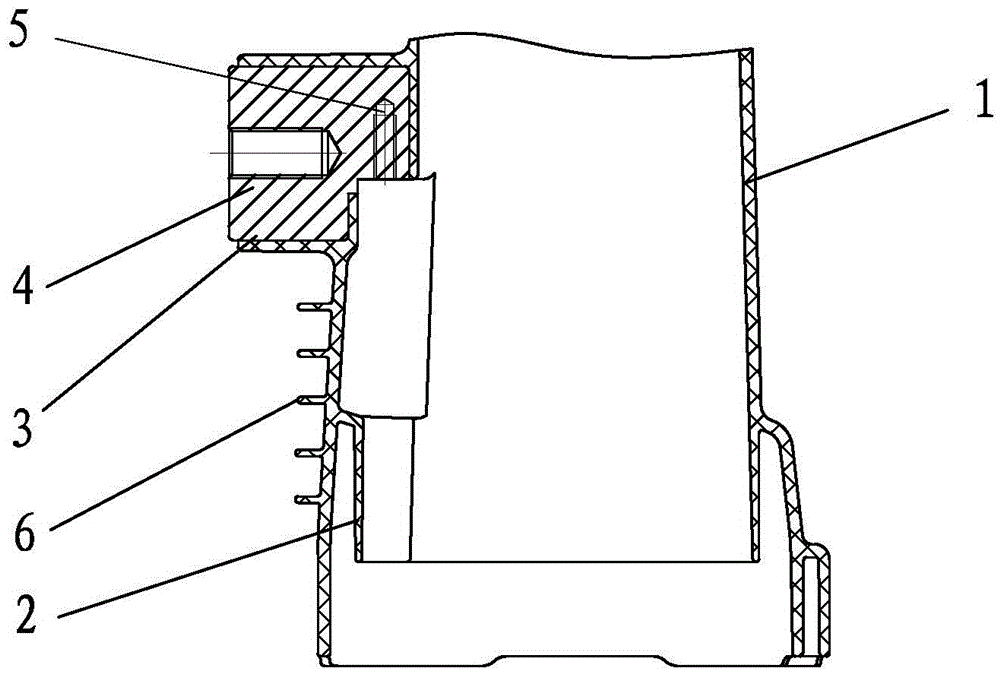

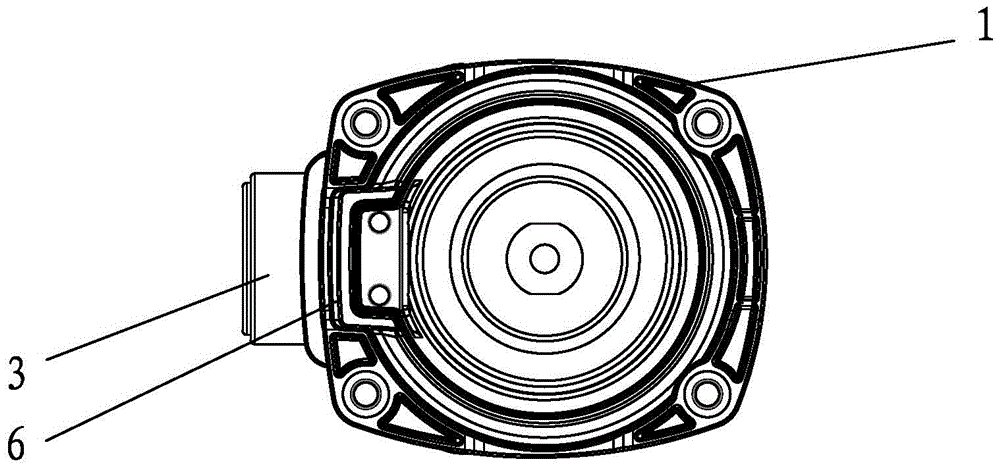

[0031] Such as figure 1 , figure 2 As shown, an embedded pole part in which the inner shed and the shell are integrally formed, including a pole part shell 1 made of thermoplastic insulating material, the inner peripheral surface of the pole part shell is provided with a Inner shed 2, said inner shed and the pole part shell adopt the same thermoplastic insulating material.

[0032] A lower outlet conductive seat 3 is provided on the side wall of the pole part shell, and a lower outlet conductor 4 is arranged inside the lower outlet conductive seat, and the inner shed is located below the lower outlet conductive seat. The inner shed is closed in the circumferential direction, the top edge of the inner shed is fixed on the inner circumferential surface of the pole part housing, the inner shed extends downwards, the bottom of the inner shed is a free end, and the outer part of the inner shed There is a gap between the circumferential surface and the inner circumferential surfa...

Embodiment 2

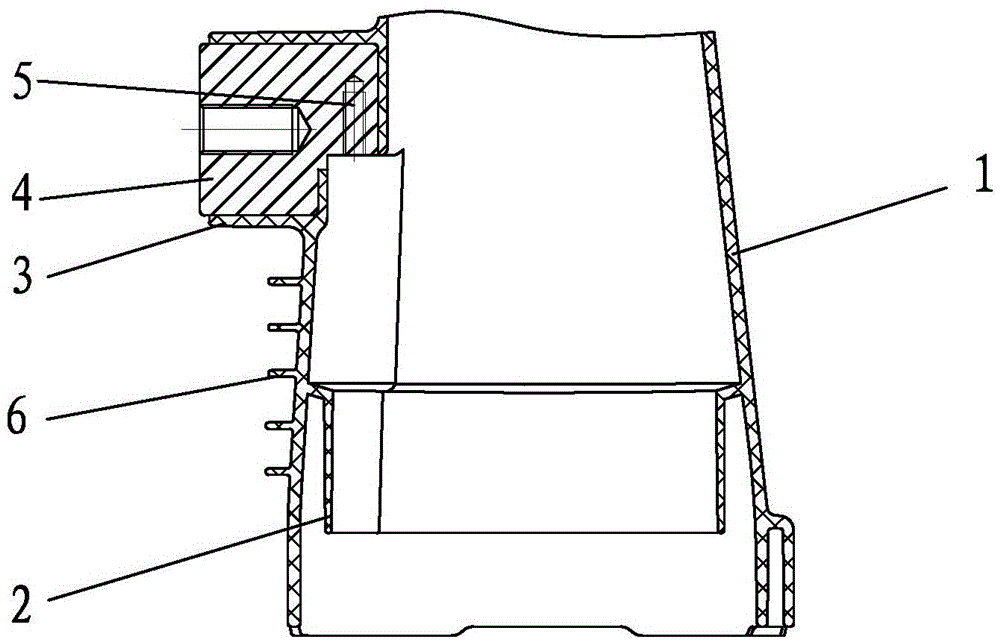

[0035] Such as image 3 As shown, an embedded pole part in which the inner shed and the shell are integrally formed, including a pole part shell 1 made of thermoplastic insulating material, the inner peripheral surface of the pole part shell is provided with a Inner shed 2, said inner shed and the pole part shell adopt the same thermoplastic insulating material.

[0036] A lower outlet conductive seat 3 is provided on the side wall of the pole part shell, and a lower outlet conductor 4 is arranged inside the lower outlet conductive seat, and the inner shed is located below the lower outlet conductive seat. The inner shed is closed in the circumferential direction, the edge of the inner shed top of the inner shed is fixed on the inner circumferential surface of the pole part shell, the inner shed extends downwards, the bottom of the inner shed is a free end, and the inner shed There is a gap between the outer peripheral surface of the skirt and the inner peripheral surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com