Protection device for high-voltage cable at train end of motor train unit and motor train unit

A technology for protective devices and EMUs, applied in locomotives, electrical components, etc., can solve the problems of cable twisting and easy overrunning of cables, and achieve the effect of avoiding wear and tear, avoiding stretching, and improving safety and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

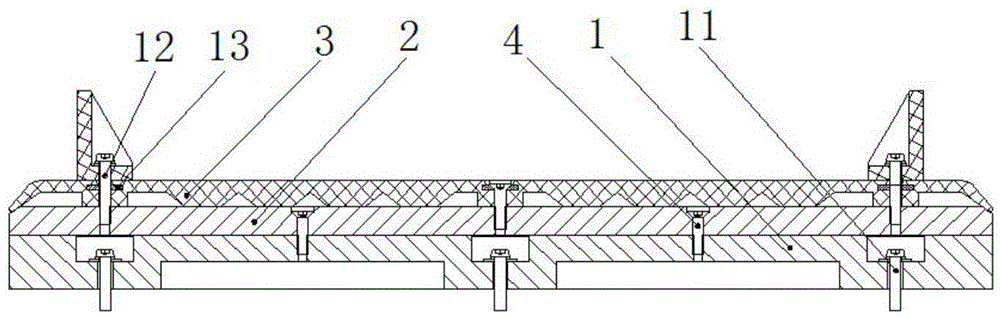

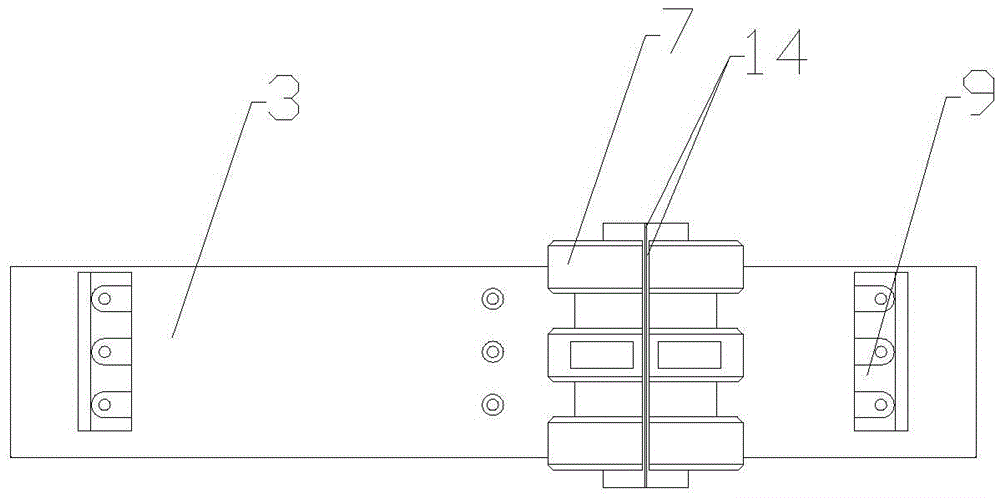

[0025] Such as figure 2 As shown, the high-voltage cable protection device at the train end of the EMU includes a base, which is a multi-layer structure, including a support base 1, a rubber cage 2 and a rubber pad 3 from bottom to top. The rubber cage 2 is fixed on the support base 1 by mounting screws 4, and the rubber pad 3 is mounted on the rubber cage 2 by bolts.

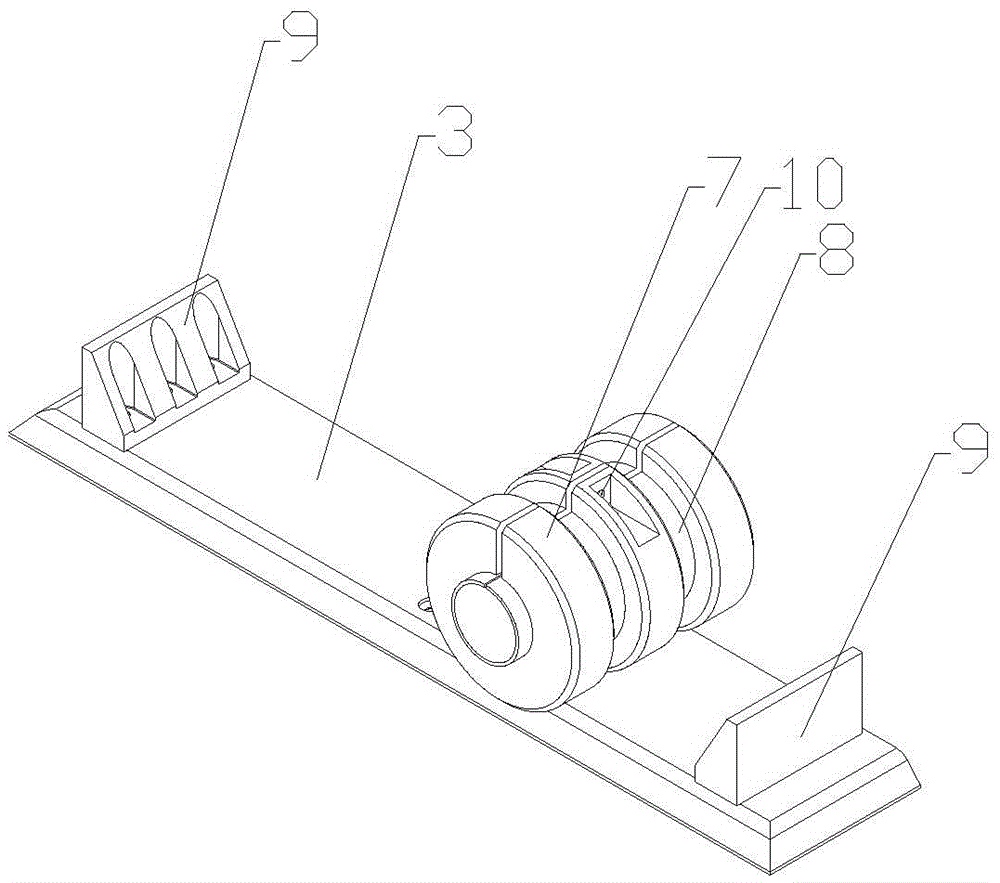

[0026] It also includes a sheath, which is lapped on the rubber pad 3 and can slide laterally along the rubber pad 3; the center of the sheath structure has a hollow hole running through the length direction of the sheath. The sheath has a multi-layer structure, from near the hollow to the outside of the hollow, sequentially including elastic rubber layer 5, steel ring layer 6 and wear-resistant rubber layer 7, elastic rubber layer 5, steel ring layer 6 and wear-resistant rubber layer 7 Each has an opening 14 running through its length, the wear-resistant rubber layer 7 has a groove 701 and a protrusion 702, ...

Embodiment 2

[0032] An EMU, equipped with a high-voltage cable protection device at the end of the EMU.

[0033] Two sets of protective devices are used in pairs and installed on two adjacent vehicles respectively. Such as figure 2 As shown, the support base is installed on the top of the adjacent place of the two vehicles by base mounting screws 11. The high-voltage cables pass through the hollow holes of the two roof sheaths in turn, and are connected to the electrical components in the car. The high-voltage cable passes through the protection device to a section connected to the electrical device in the car, and is fixed between the fixing parts installed at intervals and the roof of the car.

[0034] Since the length of the high-voltage cables at the train end of the EMU is carefully calculated, it will not be designed too long. Therefore, the high-voltage cables will not leave too much movement margin. Therefore, during the movement of the EMU, the high-voltage cables only Lateral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com