Collision energy-dissipation spacing rod

A technology of spacers and metal hollow spheres is applied in the installation of devices, electrical components, and cables that maintain the distance between parallel conductors. Well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

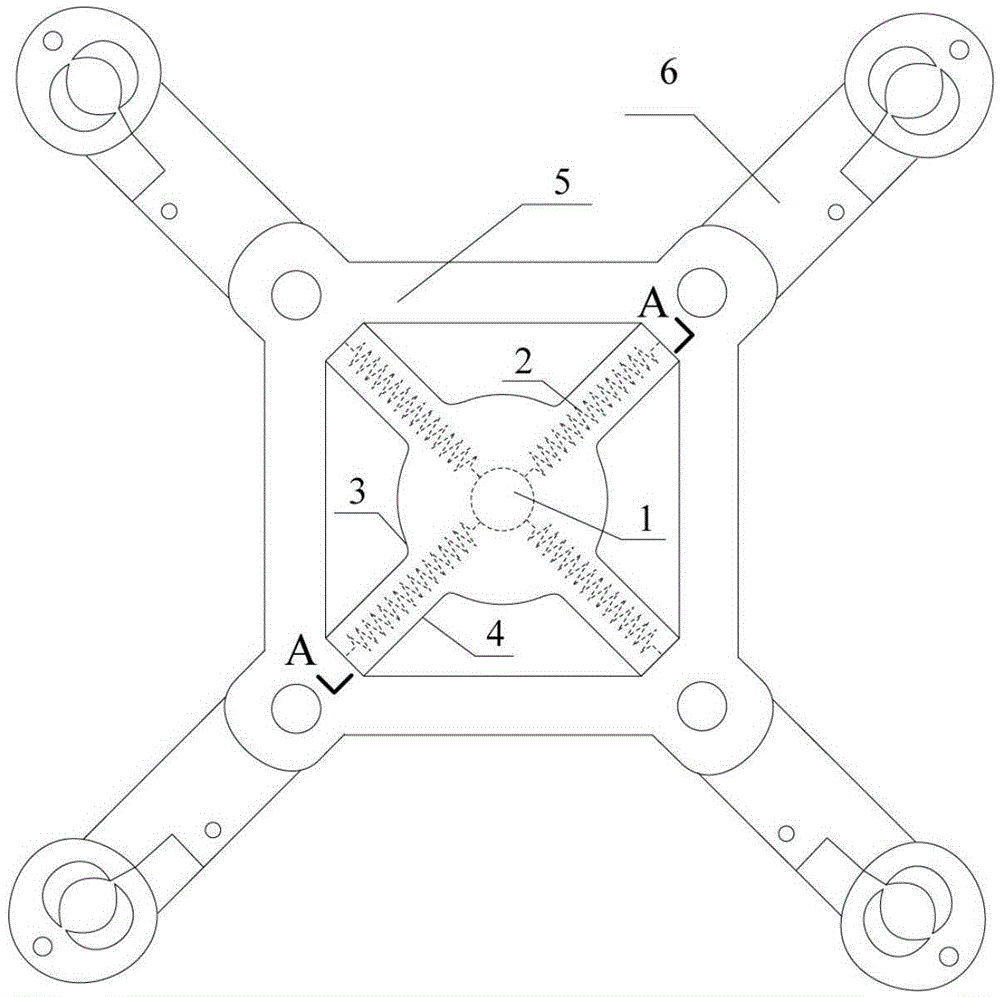

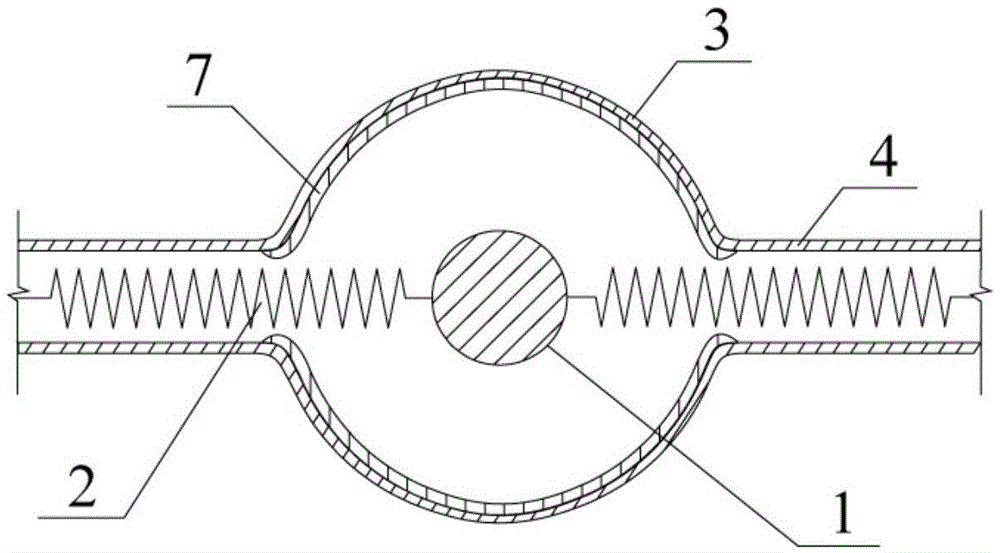

[0010] Such as figure 1 , figure 2 A collision energy-dissipating spacer is shown, which is composed of a mass ball 1, a spring 2, a metal hollow ball 3, a metal tube 4, a spacer frame 5, a wire clip 6 and a viscoelastic material layer 7.

[0011] The metal hollow ball 3 is a hollow sphere structure, and the surroundings are connected with the metal round pipe 4 with openings, and the joints with the metal round pipe 4 are smoothed to prevent the spring 2 from being stuck. Both the mass ball 1 and the viscoelastic material layer 7 are located inside the metal hollow ball 3: the mass ball 1 is suspended in the metal hollow ball 3, and the suspension point is located at the center of the metal hollow ball 3; the viscoelastic material layer 7 is attached It is arranged on the inner wall of the metal hollow ball 3, so as to play the role of energy absorption, energy consumption and vibration reduction. The other end of the metal circular tube 4 is fixedly connected with the spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com