Pole iron drive device

A driving device, permanent magnet technology, applied in the directions of generators/motors, electrical components, etc., can solve the problems of slow movement speed and high power consumption, and achieve the effect of saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific embodiment that the present invention provides is described in further detail below in conjunction with accompanying drawing:

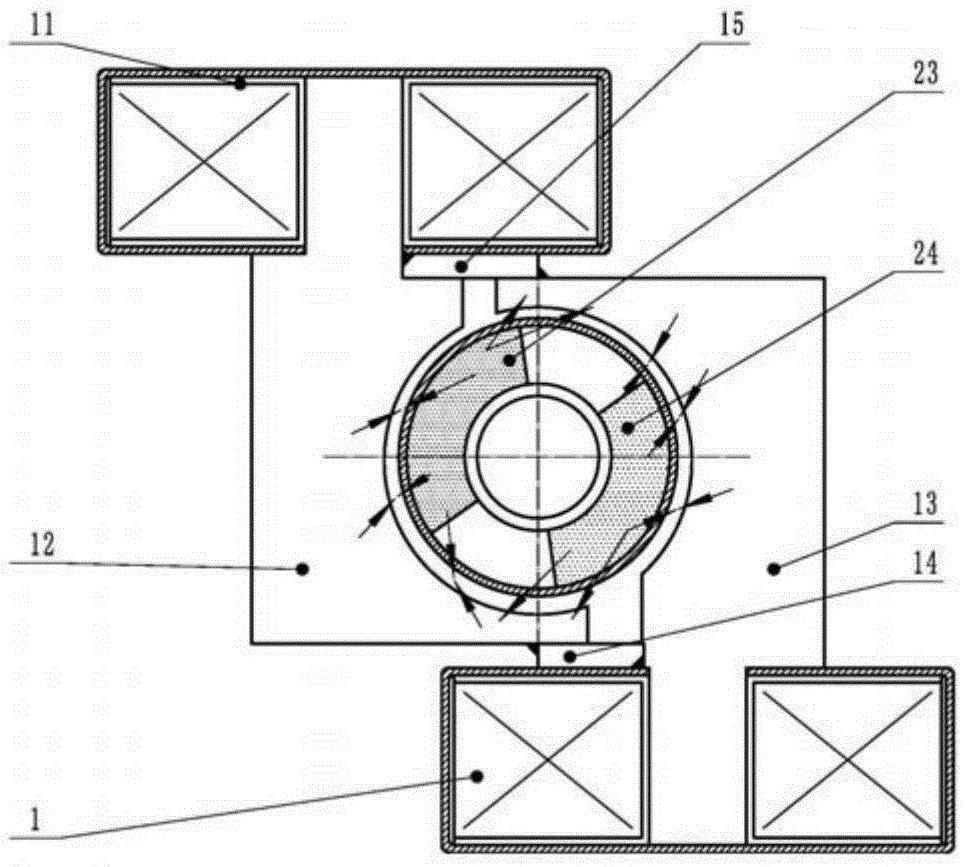

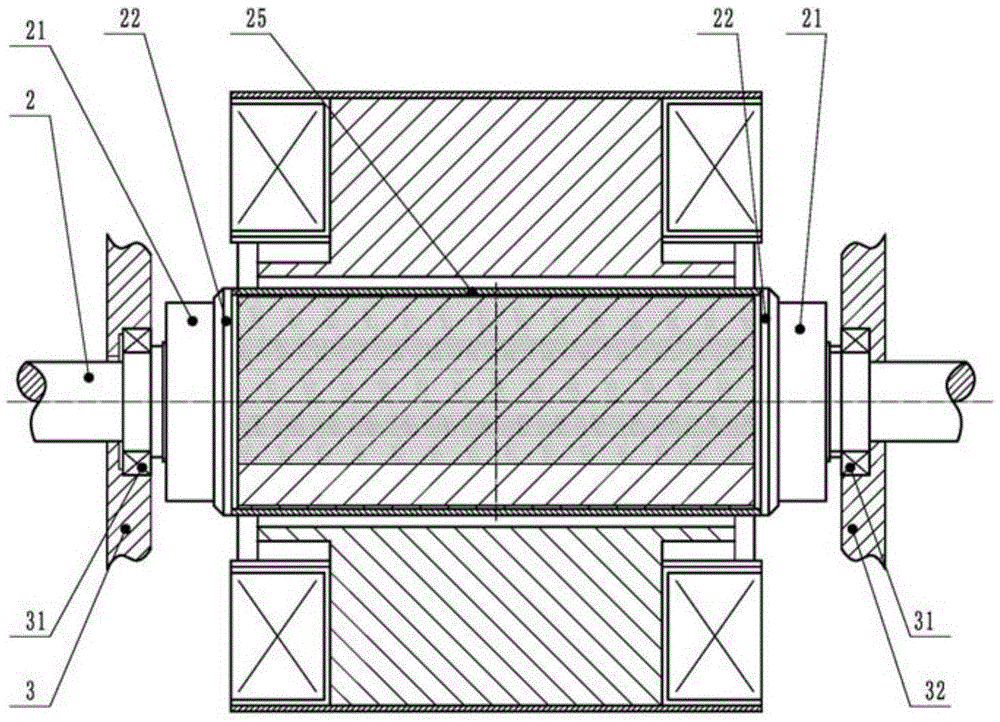

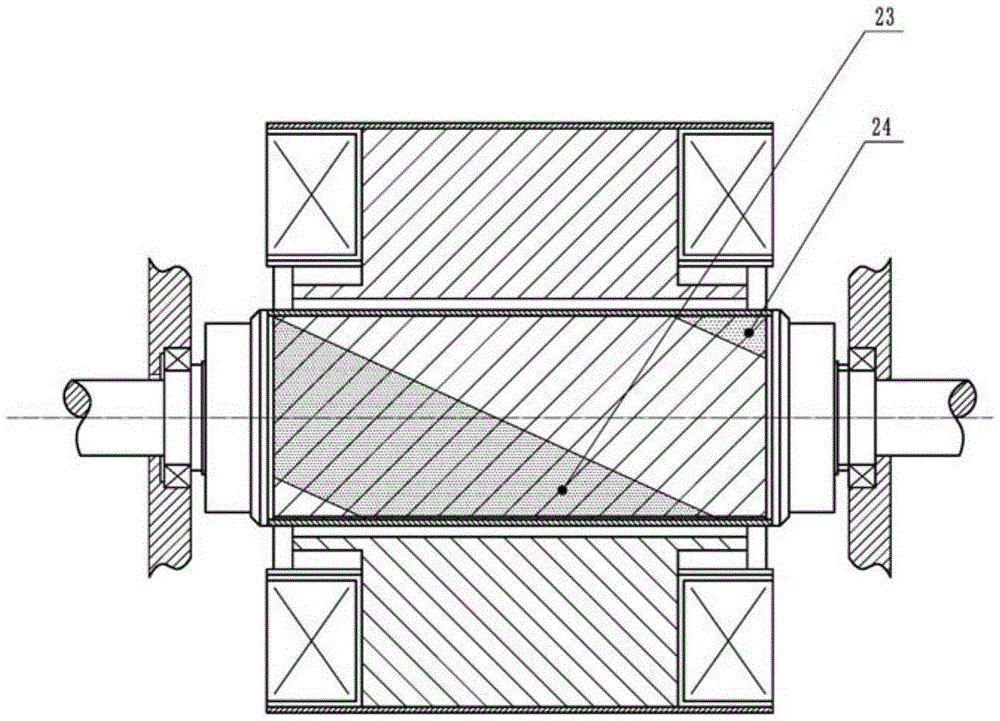

[0046] As shown in Fig. 1 (a), (b), be the structural representation of the first embodiment of the present invention, the device of this embodiment comprises:

[0047] The first component includes a first coil 1 and a second coil 11, a first pole iron 12, a second pole iron 13, a first connecting piece 14, and a second connecting piece 15, the first coil 1 and the second coil 11 Installed on both sides of the vertical center line and on the opposite side of the horizontal center line respectively, the diagonally separated first pole iron 12 and the second pole iron 13 are installed on the outside of the wall of the protruding iron, and the section of the protruding iron can be Rectangular, square, elliptical or circular, the first pole iron 12 and the second pole iron 13 are located below the bottom sides of the first coil 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com