Method for producing a twin screw cylinder provided with a wear-protective layer

A technology of twin-screw and protective layer, which is used in the field of manufacturing twin-screw cylinders with wear protective layer, can solve the problem of high cost and achieve the effect of reducing operating expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

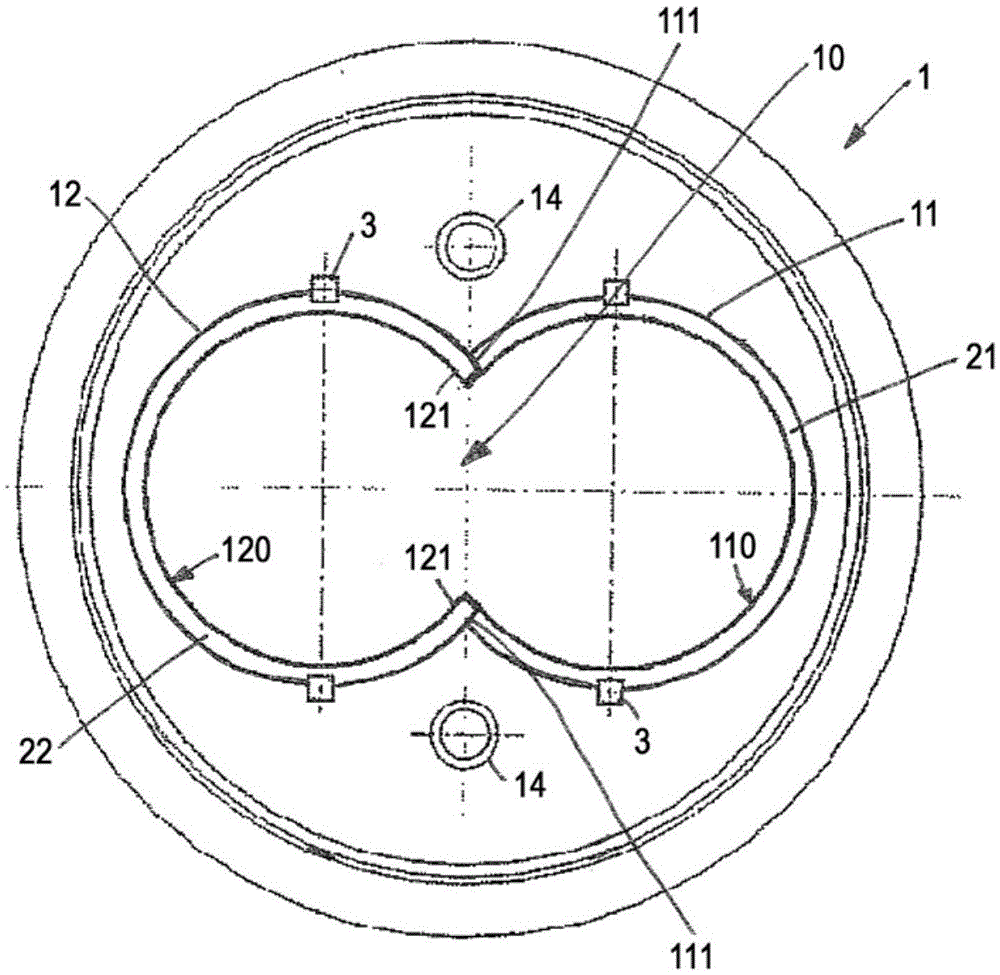

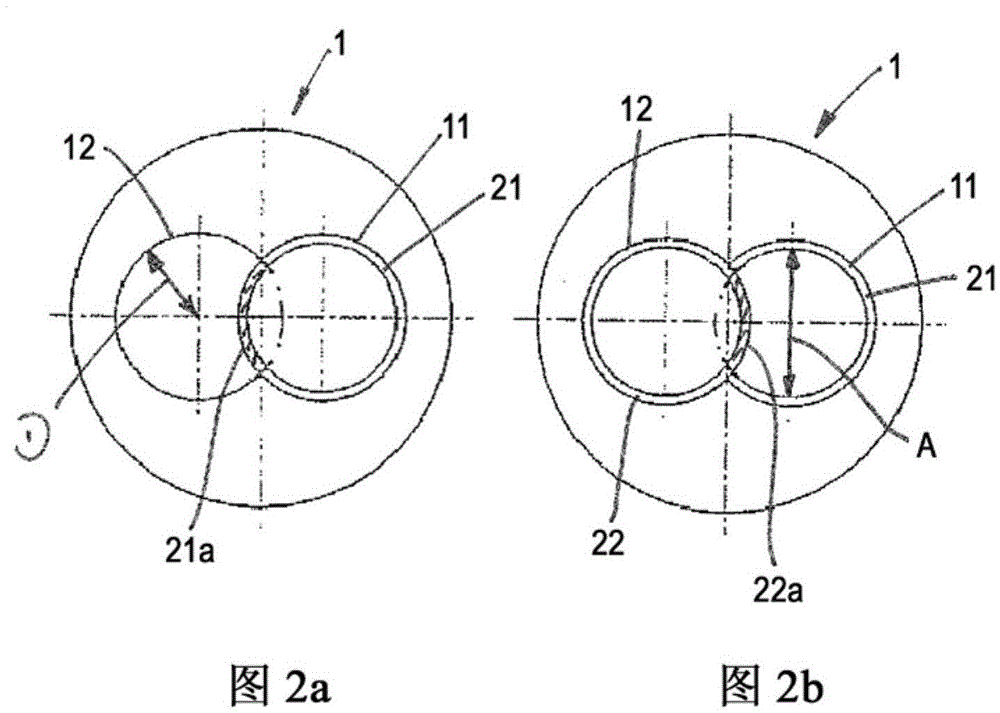

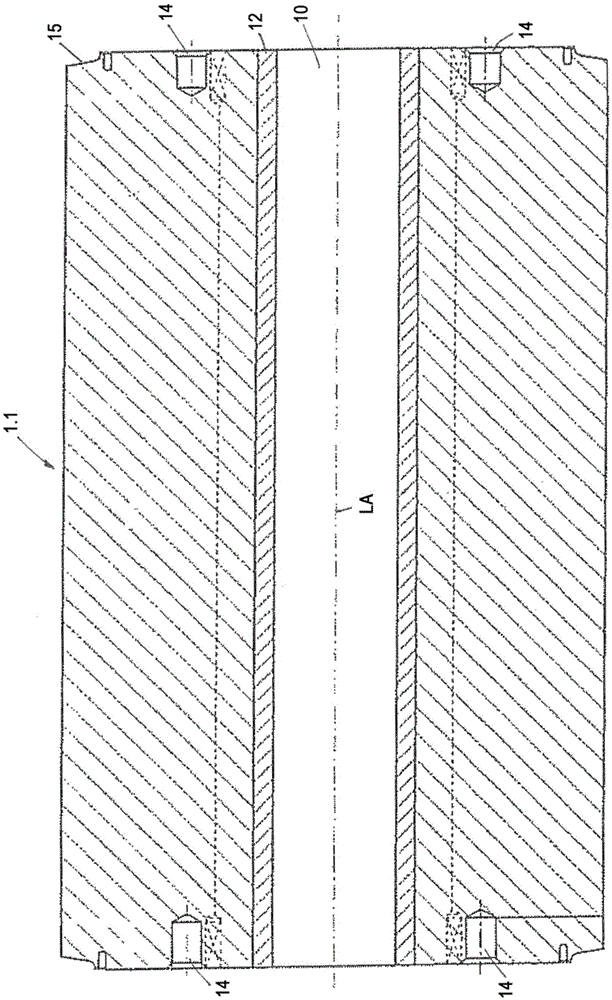

[0031] figure 1 shows a twin-screw cylinder designated as a whole by the reference numeral 1 in a known manner as a component of a corresponding twin-screw extruder for plastics processing, the twin-screw cylinder With a cylindrical base body made of a suitable metallic material, two bore holes 10 , 11 which in the illustrated embodiment run exactly parallel to one another and have the same diameter are introduced into the base body in such a way that the two bore holes pass through each other and delimit an overlapping region 10 here.

[0032] Each of the two boreholes 11 , 12 is provided with an inner lining 21 , 22 with a substantially C-shaped cross-section, which extend mutually to each other in the overlapping region 10 so that the borehole The entire inner surface of 11 , 12 is covered by inner lining layers 21 , 22 . The inner linings 21 , 22 here are made of a suitable, for example bimetallic material and serve as a wear protection layer for being accommodated insid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com