Measurement device and method for transmission wavefronts of self-focusing lens

A technology of self-focusing lens and measuring device, which is applied in the field of optics, can solve the problems of affecting measurement results, large numerical aperture, and small size, and achieve the effects of improving measurement accuracy, high confidence, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

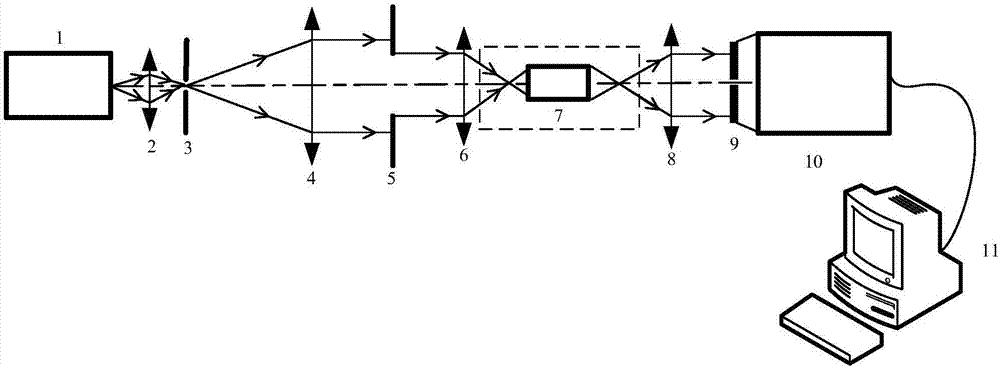

[0035] see figure 1 , the present invention provides a self-focusing lens transmission wavefront measurement device, the self-focusing lens transmission wavefront measurement device includes a light source 1, a converging mirror 2, a target plate 3, a collimating mirror 4, a diaphragm 5, a first microscope Objective lens 6, second microscope objective lens 8, positioning reference structure 9, Shack-Hartmann wavefront sensor 10 and computer 11; converging lens 2, target plate 3, collimating lens 4, aperture 5, first microscope The objective lens 6, the second microscopic objective lens 8, the positioning reference structure 9 and the Shaker-Hartmann wavefront sensor 10 are sequentially arranged on the outgoing light path of the light source 1; the Shaker-Hartmann wavefront sensor 10 is connected to the computer 11; The self-focusing lens 7 to be tested is placed between the first microscopic objective lens 6 and the second microscopic objective lens 8 . figure 1 In , the blac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com