A mixed non-metallic ore clay-loaded γ‑mno 2 Low-temperature denitrification catalyst and preparation method thereof

A non-metallic ore, low-temperature denitrification technology, applied in the field of denitrification catalysis, can solve the problems of high reaction temperature and expensive catalyst carrier, and achieve the effects of low activation temperature, abundant reserves and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1. Dissolve 10g of sepiolite clay and 10g of attapulgite clay in 1.5mol / L HCl until the solution does not produce bubbles, and let stand for 18h. Disperse the acidified non-metallic ore clay in deionized water, use a 4000r / min emulsifier to pulp, and select the supernatant to obtain a 4g / 100mL suspension slurry;

[0018] 2. At room temperature, dissolve 100mL of MnSO with a mass concentration of 3g / 100mL 4 ·H 2 O and 130mL mass concentration of 3g / 100mL (NH 4 ) 2 S 2 o 8 Put the solution in 500mL step (1) slurry, keep stirring, raise the temperature to 80°C for 2h; after the reaction is complete, filter the product with suction, wash and dry to obtain 7wt.% γ-MnO 2 - Sepiolite clay / attapulgite clay low-temperature denitrification catalyst.

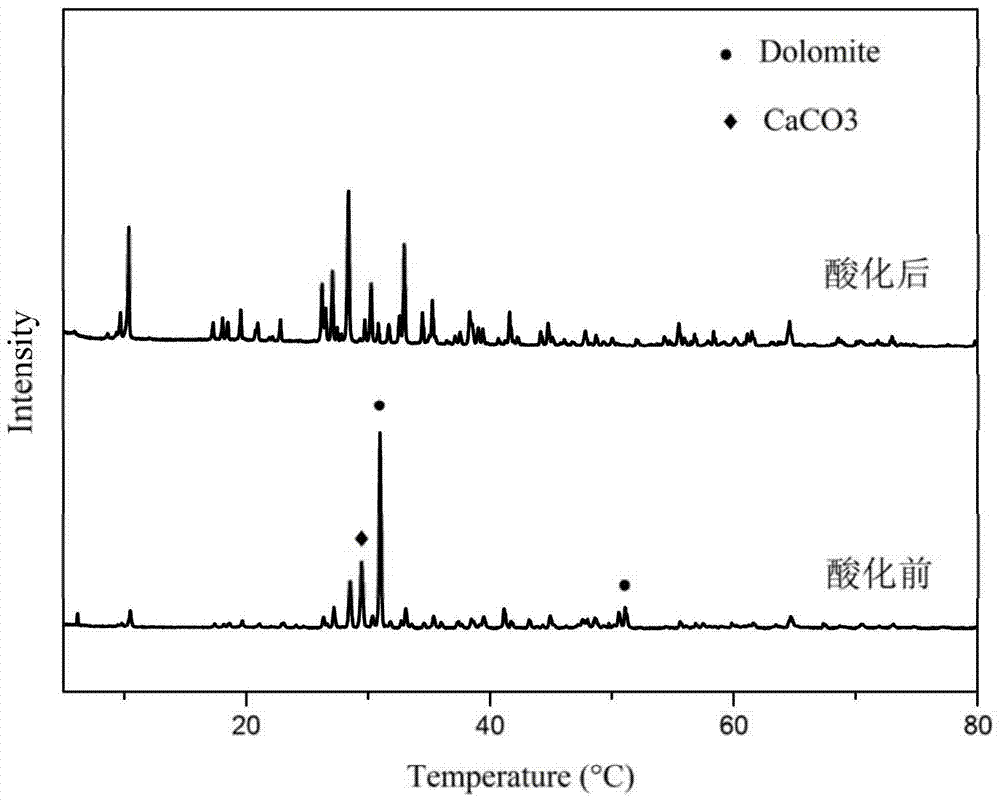

[0019] figure 1 It is the XRD pattern of sepiolite before and after acidification. According to the preparation method in Example 1, sepiolite is prepared by reacting in 1.5mol / L HCl; it can be clearly seen from the figure th...

Embodiment 2

[0022] 1. Dissolve 15g of sepiolite clay and 5g of montmorillonite clay in 1.5mol / L HCl until the solution does not produce bubbles, and let it stand for 24 hours. Disperse the acidified non-metallic mineral clay in deionized water, use a 5000r / min emulsifier to pulp, and select the supernatant to obtain a 5g / 100mL suspension slurry;

[0023] 2. At room temperature, dissolve 60mL of MnSO with a mass concentration of 5g / 100mL 4 ·H 2 O and 80mL mass concentration of 5g / 100mL (NH 4 ) 2 S 2 o 8 Put the solution in 400mL of step (1) slurry, keep stirring, raise the temperature to 75°C for 2.5h; after the reaction is complete, filter the product with suction, wash and dry to obtain 7wt.% γ-MnO 2 -Sepiolite clay / montmorillonite clay low-temperature denitrification catalyst.

Embodiment 3

[0025] 1. Dissolve 10g of sepiolite clay and 10g of cordierite clay in 2.5mol / L HCl until the solution does not produce bubbles, and let stand for 20h. Disperse the acidified non-metallic ore clay in deionized water, use a 4000r / min emulsifier to pulp, and select the supernatant to obtain a 8g / 100mL suspension slurry;

[0026] 2. At room temperature, dissolve 75mL of MnSO with a mass concentration of 4g / 100mL 4 ·H 2 O and 100mL mass concentration of 4g / 100mL (NH 4 ) 2 S 2 o 8 Put the solution in 250mL step (1) slurry, keep stirring, and heat up to 85°C for 1.5h; after the reaction is complete, filter the product with suction, wash, and dry to obtain 7wt.% γ-MnO 2 -Sepiolite clay / cordierite clay low-temperature denitrification catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com