Ventilated device for ink transportation mechanism

A technology of ink feeding and ventilator, which is applied to printing presses, rotary printing presses, general parts of printing machinery, etc., to achieve the effect of saving time-consuming matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

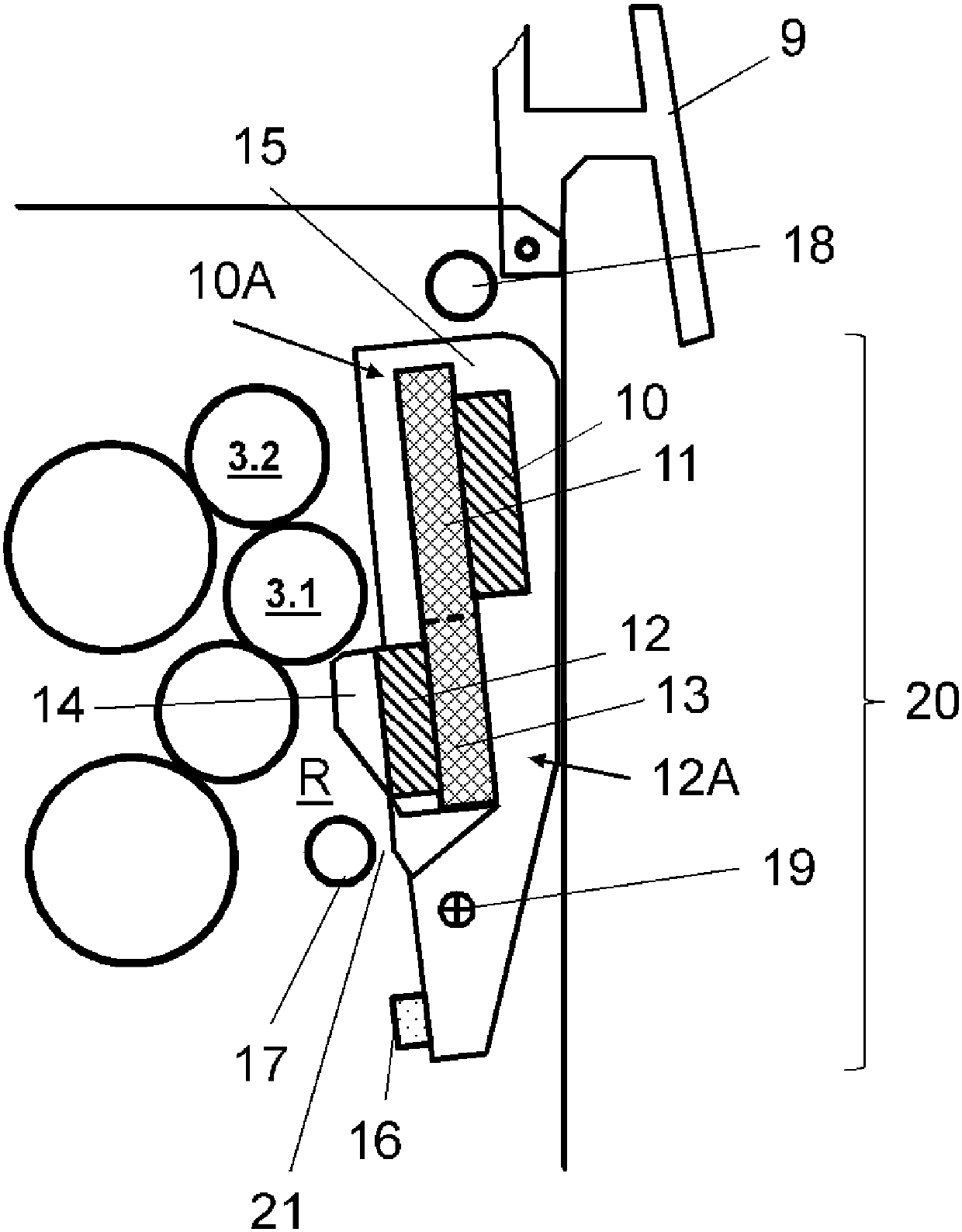

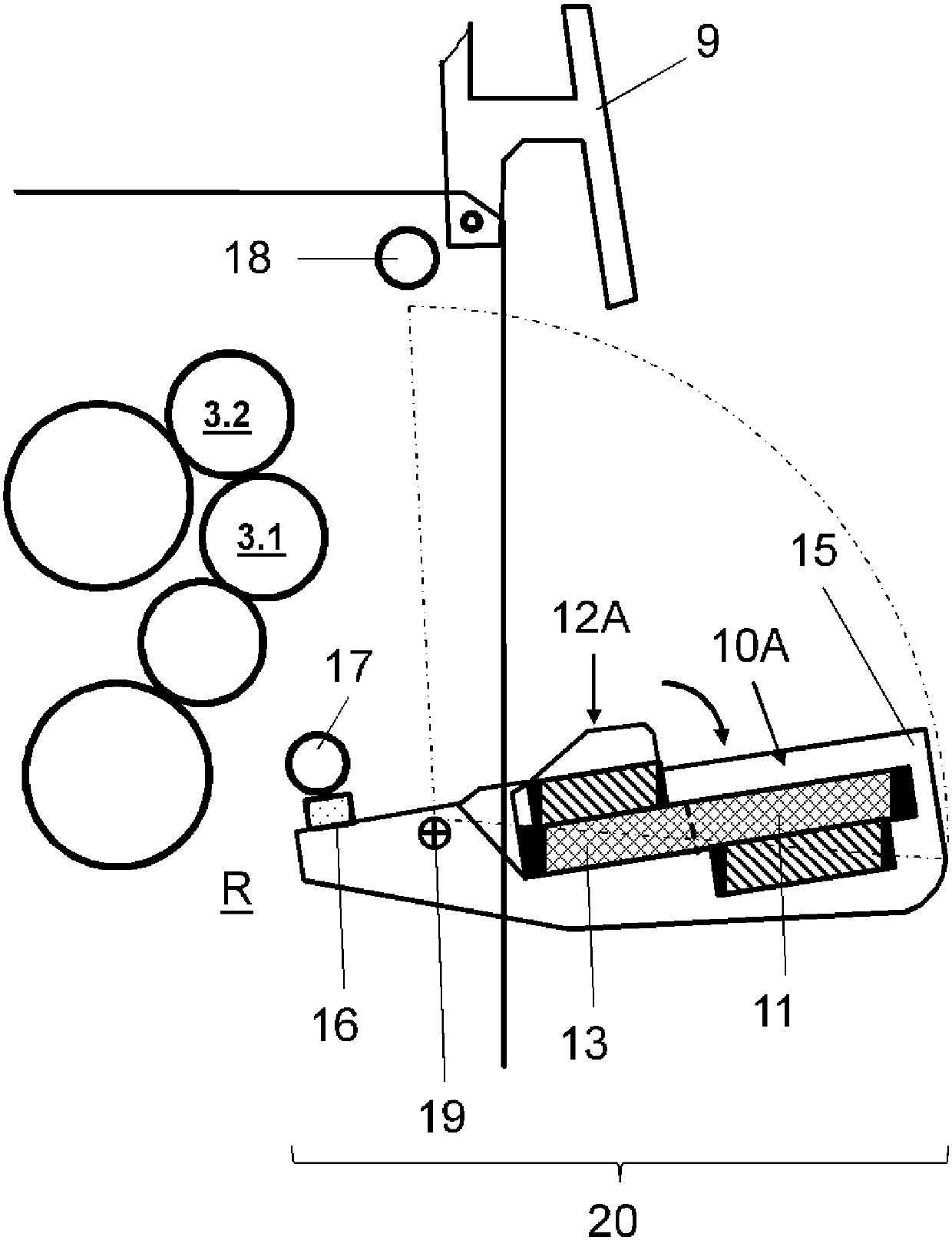

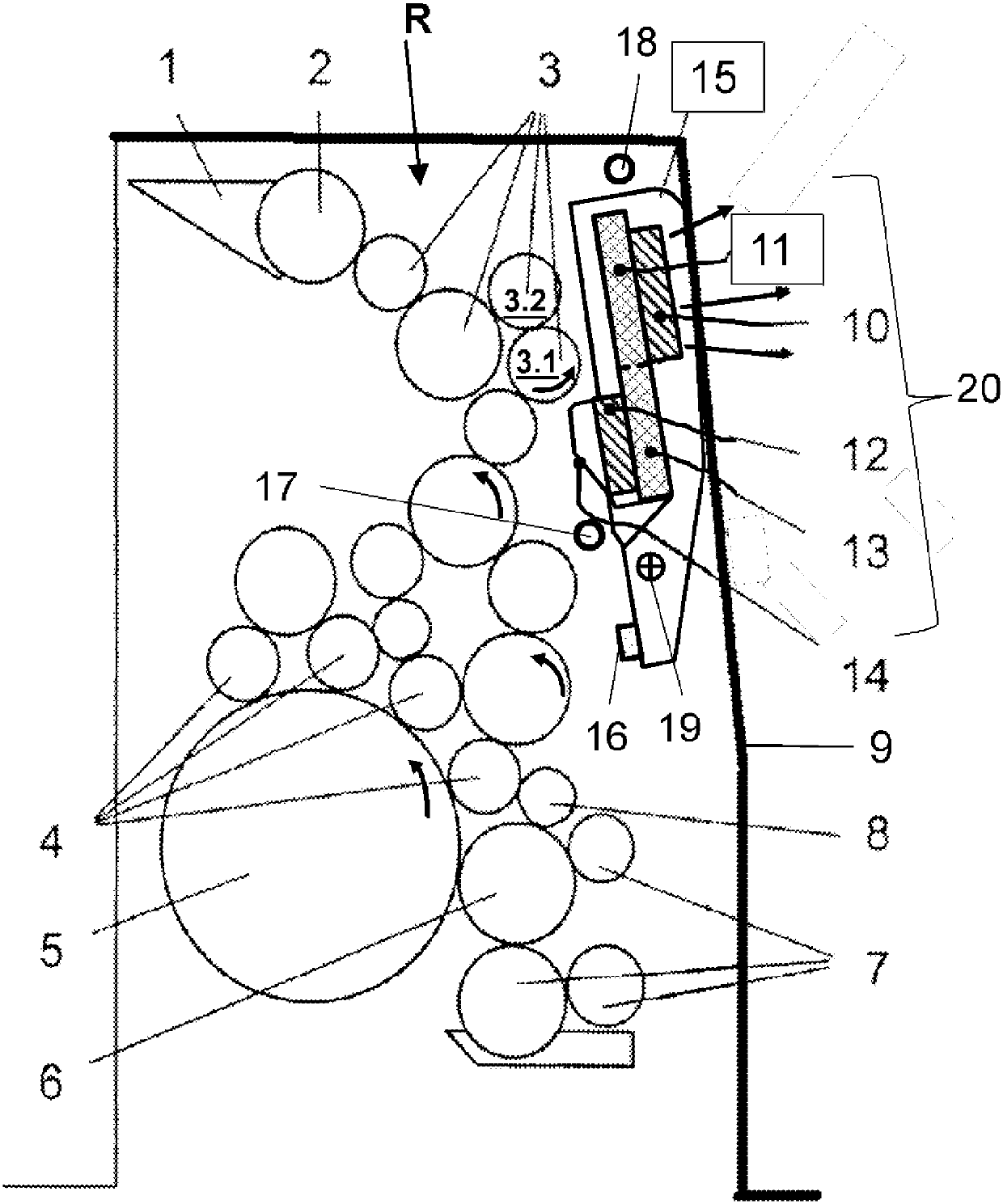

[0051] figure 1In the inking unit space R, an inking unit with a suction device 10A is shown. From the fountain 1 , the ink to be printed is applied via the fountain roller 2 , the inking unit roller 3 arranged downstream of the fountain roller 2 , and via the inking roller 4 onto the printing form stretched onto the plate cylinder 5 . A dampening applicator roller 6 is arranged upstream of the inking roller 4 in the direction of rotation of the plate cylinder 5 (counterclockwise). The dampening applicator roller 6 cooperates with the dampening roller 7 of the dampening mechanism. The wet applicator roller 6 is connected to the first inking roller 4 of the inking unit via a bridge roller 8 . The inking unit rollers 3 of the inking unit are covered by a displaceable, pivotable and pivotable printing unit guard 9 from the side of the feeder, not shown. A row of axial fans 10 is arranged on the printing unit guard 9 extending over the dimension width of the printing press, by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com