High pressure injection system having fuel cooling from low pressure region

A high-pressure injection and fuel injection valve technology, which is applied to fuel injection devices, charging systems, engine components, etc., can solve problems such as increased fuel wear, high structural consumption, additional cost, and large engine space consumption. Design structure changes , to achieve a cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

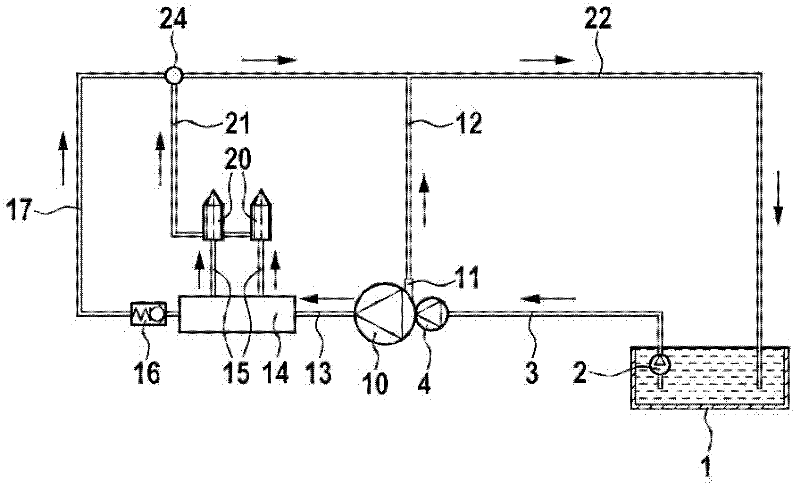

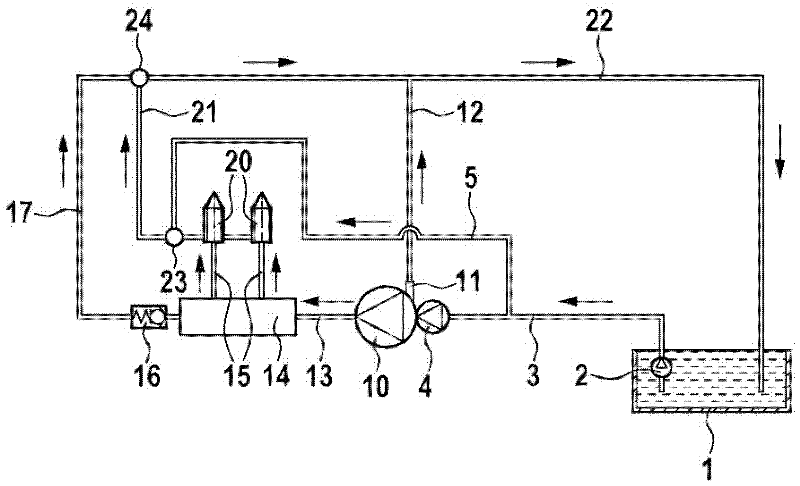

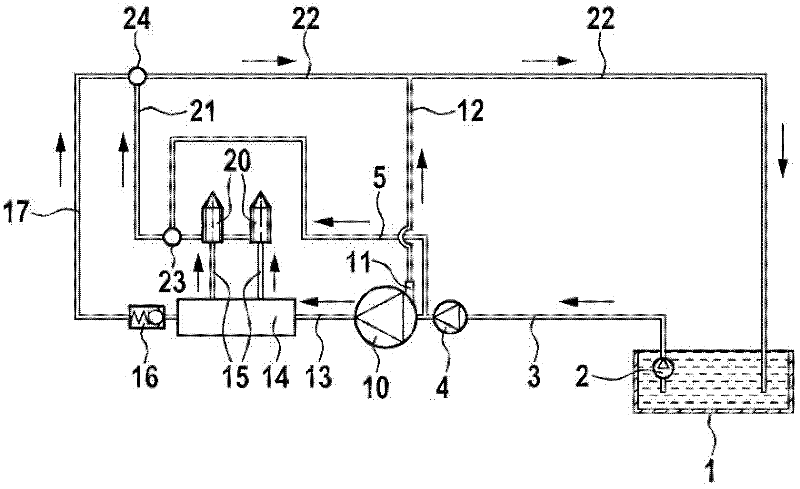

[0017] figure 1 A schematic diagram showing a high-pressure injection valve known from the prior art. The fuel is fed from the fuel tank 1 to the front-stage transfer pump 4 via the connecting pipe line 3 by means of the fuel transfer pump 2 and is fed to the high-pressure pump 10. The fuel tank 1, the fuel delivery pump 2, the connecting pipe 3, and the front delivery pump 4 are subjected to low pressure, and therefore are classified into the low pressure area.

[0018] A fuel return portion 11 is arranged on the high-pressure pump 10, and the fuel return portion 11 is connected to the fuel tank 1 via a return line 12 and another return line 22. In addition, the high-pressure pipe 13 passes from the high-pressure pump 10 to the high-pressure accumulator 14, the high-pressure accumulator 14 is also called a common rail, and the high-pressure accumulator 14 is connected to the fuel injection valve 20 via another high-pressure pipe 15. Here, the existing high-voltage storage 14 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com