Weaving cage rebar storage rack used for pipe pile production line and weaving cage rebar conveying device

A technology of conveying device and storage rack, applied in the field of construction, can solve the problems of low degree of automation and low production efficiency, and achieve the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

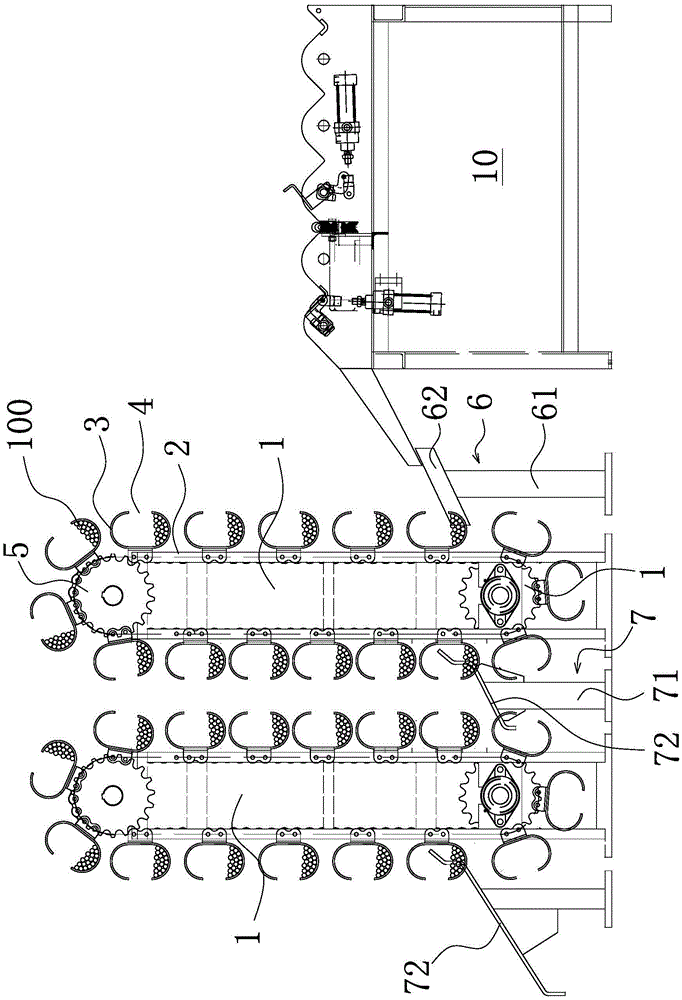

[0034] Such as figure 1 As shown, a storage rack for braided steel bars used in a pipe pile production line includes a storage rack body 1, and the storage rack body 1 is provided with a conveyor chain 2 that can rotate along the circumference of the storage rack body 1 and is transported The chain 2 is fixedly connected with a number of steel bar accommodation frames 3, and the steel bar accommodation frames 3 can support the weaving steel bars 100 so that the weaving cage steel bars 100 are placed in the steel bar accommodation frames 3. When one of the steel bars is accommodated When the number of caged steel bars of frame 3 reaches the set number, if it is necessary to compile a steel bar cage with 8 steel bars, then set the number of steel bar accommodation frame 3 to 8, and the conveyor chain 2 can drive the steel bar with the steel bar. Another steel bar storage frame 3 adjacent to the storage frame 3 arrives at the position of the steel bar storage frame 3, that is, af...

Embodiment 2

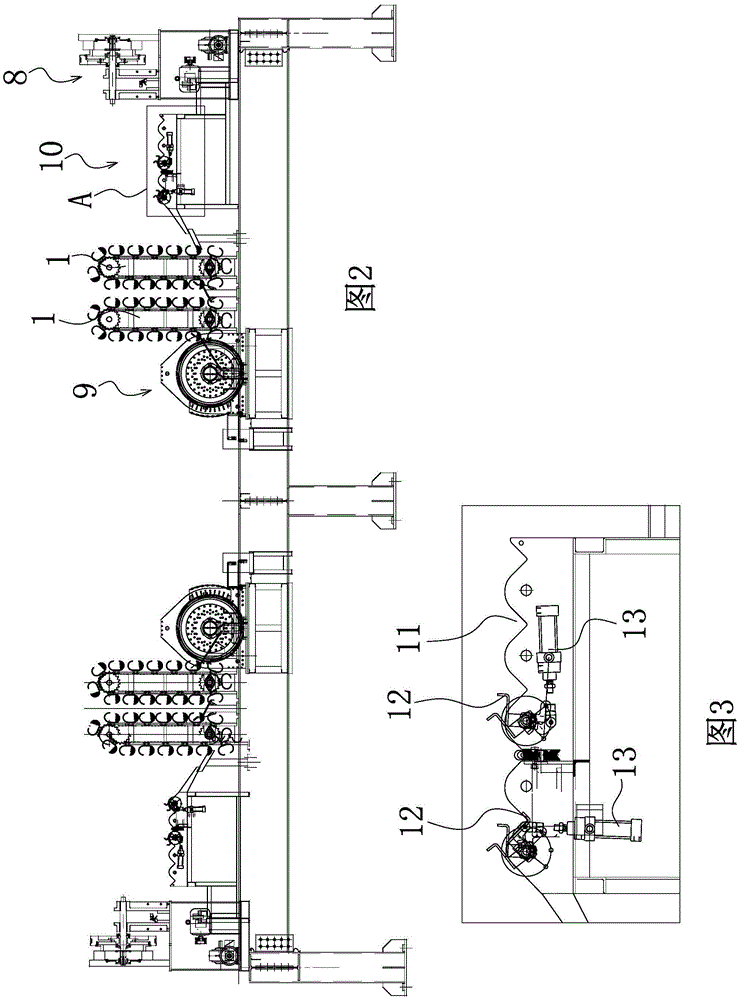

[0042] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that, as figure 2 As shown, the present embodiment provides a cage weaving steel bar conveying device, and the two sides of the storage rack body 1 are respectively provided with a steel bar pier 8 and a cage weaving machine 9 . Reinforcing bar pier machine 8 and weaving cage machine 9 are prior art, no longer repeat them here. What this embodiment provides is through automatic storage after the steel bar is processed by the pier head, and then automatically unloads the automatic conveying device to the cage machine 9. As mentioned above, the cage steel bar 100 is exported by the discharge guide plate 72, when it is discharged When the material guide plate 72 position corresponds to the position of the weaving cage machine 9, the cage weaving steel bar 100 can be directly put into the weaving cage machine 9 to implement the weaving cage work.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com