A method for extracting tomato pomace by subcritical fluid

A subcritical fluid and tomato pomace technology, applied in extraction, purification/separation, organic chemistry, etc., can solve the problem of strict water content in tomato pomace, and achieve good extraction of active substances, good extraction efficiency, equipment and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

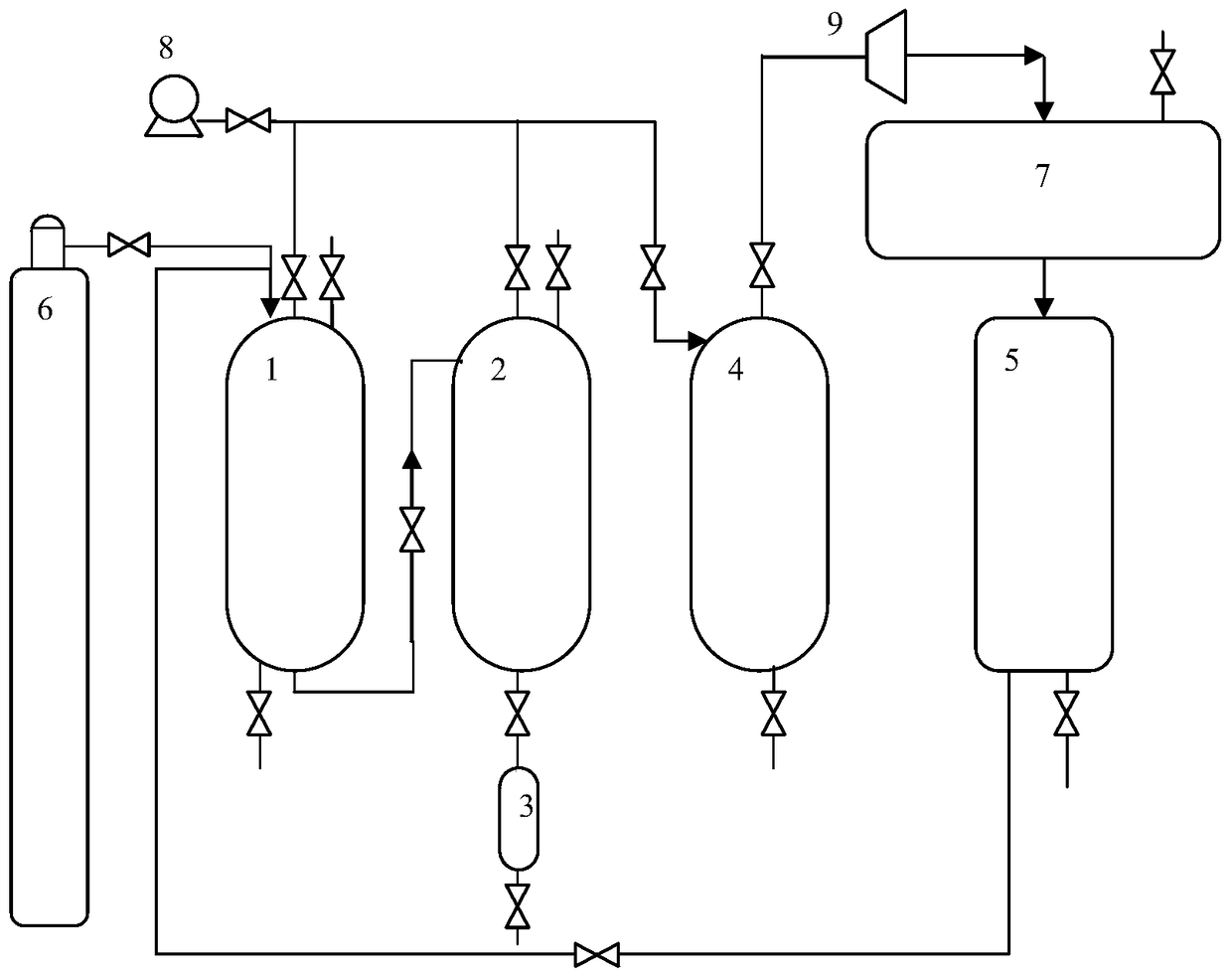

Method used

Image

Examples

Embodiment 1

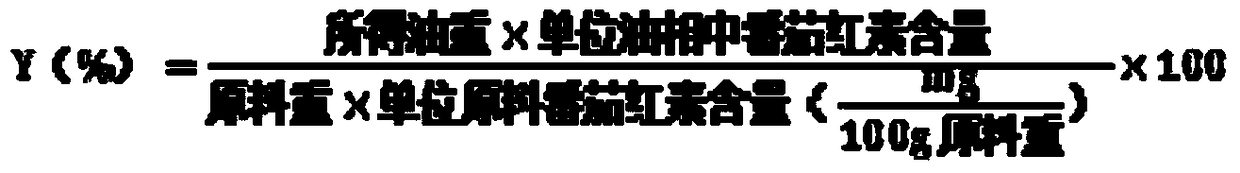

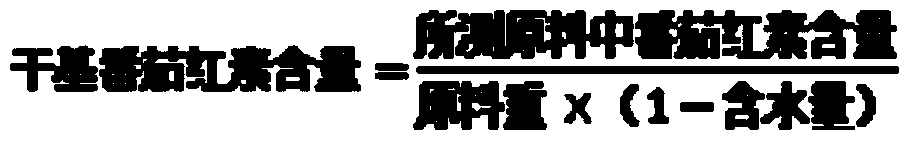

[0044] The particle size of the pulverized tomato pomace is controlled at 80-100 mesh, the water content of the tomato pomace is controlled at 90wt%, and 3500g of the above-mentioned tomato pomace is weighed (the determined lycopene content is 18.6mg / 100g), and put into a subcritical extraction kettle , pass into the subcritical fluid of methyl ether, the weight ratio of the subcritical fluid of methyl ether to the tomato pomace is 1:20, control the flow rate to extract at 50kg / h, under the extraction temperature of 15°C and the pressure of 0.4MPa, make The methyl ether subcritical fluid is completely submerged in the tomato peel for extraction, and the extraction is continuously circulated for 6 hours to obtain a tomato peel extraction mixture.

[0045] Control the separation temperature to 40°C and the separation pressure to 0.2 MPa. After separation, the fat-soluble organic phase containing lycopene and the aqueous solution mixture are obtained. After the organic phase is se...

Embodiment 2

[0047] The particle size of the pulverized tomato pomace is controlled at 60-80 mesh, the water content of the tomato pomace is controlled at 50wt%, and 700g of the above-mentioned tomato pomace is weighed (the determined lycopene content is 17.8mg / 100g), and put into a subcritical extraction kettle , pass into the mixed fluid of methyl ether and butane, the volume ratio of methyl ether and butane is 1:1, the weight ratio of the subcritical fluid and tomato pomace is 1:5, and the control flow is extracted at 5kg / h, At an extraction temperature of 40° C. and a pressure of 1 MPa, the subcritical fluid was completely submerged in tomato peels for extraction, and the extraction was carried out continuously for 4 hours to obtain a tomato peel extraction mixture.

[0048] Control the separation temperature to be 60° C. and the separation pressure to be 0.8 MPa. After separation, the fat-soluble organic phase containing lycopene and the aqueous solution mixture are obtained. extract)...

Embodiment 3

[0050] The particle size of the pulverized tomato pomace is controlled at 60-80 mesh, the water content of the tomato pomace is controlled at 50wt%, and 700g of the above-mentioned tomato pomace is weighed (the determined lycopene content is 15.2mg / 100g), and put into a subcritical extraction kettle , pass into the mixed subcritical fluid of methyl ether and butane, the volume ratio of methyl ether and butane is 3:2, the weight ratio of the subcritical fluid and tomato pomace is 1:10, and the flow rate is controlled at 10kg / h For extraction, at an extraction temperature of 40° C. and a pressure of 1 MPa, the subcritical fluid is completely submerged in the tomato peel for extraction, and the extraction is carried out in a continuous cycle for 4 hours to obtain a tomato peel extraction mixture.

[0051] Control the separation temperature to be 60° C. and the separation pressure to be 0.8 MPa. After separation, the fat-soluble organic phase containing lycopene and the aqueous sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com