Water drop sensor fabric and production method thereof

A technology of water drop sensor and fabric, which is applied in fabrics, textiles, textiles and papermaking, etc., can solve the problems of shape retention and poor firmness of knitted fabrics, and achieve the effect of convenient yarn cutting and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

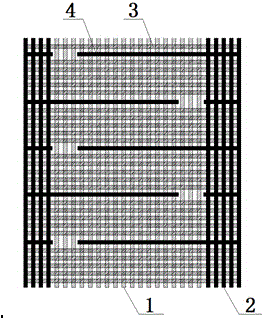

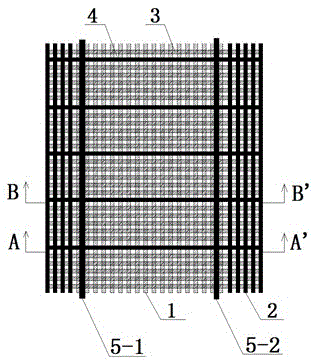

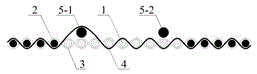

[0023] figure 1 Among them, the water drop sensor fabric is composed of non-conductive warp yarn 1, conductive warp yarn 2, non-conductive weft yarn 3 and conductive weft yarn 4. As the main yarn interweaves with two warp yarns to form the main body of the fabric, the conductive weft yarn 4 is used as a functional yarn, arranged at a certain distance along the warp direction, and alternately disconnected at a certain distance near the left and right selvedges, thereby forming a grid electrode.

[0024] figure 1 The basic structure and principle of the water drop sensor fabric are shown. However, there are many types of textile yarns. What kind of yarns should be used for non-conductive yarns and conductive yarns to ensure reliable performance and rapid response needs to be further optimized in combination with experiments.

[0025] First of all, it is necessary to select a suitable non-conductive yarn. At present, traditional yarns such as cotton, wool, silk and hemp and var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com