Needled temple

A technology of needling and temples, which is applied in the direction of textiles, textiles, papermaking, and auxiliary equipment for weaving. It can solve the problems of insufficient tension in the weft direction, and achieve the effects of simple processing, convenient installation, and improved quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

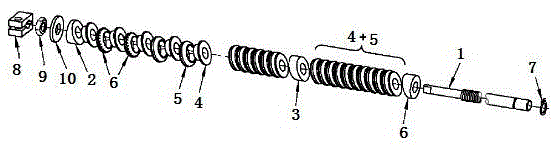

[0017] refer to figure 2 As shown, a needle-punched temple includes a support shaft 1, a first gasket 2, a snap ring 7, a clamp block 8, a nut 9 and a washer 10, and the two ends of the support shaft 1 are respectively provided with the clips spring 7 and the clamp block 8, the nut 9 is connected in series next to the clamp block 8, the nut 9 is connected in series with the washer 10, and the washer 10 and the clamp spring 7 are respectively provided with 1 said first spacer 2.

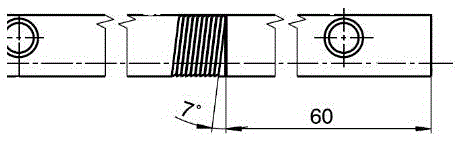

[0018] Further, a second gasket 3 , an eccentric ring 4 , a rubber ring 5 and a needle-punched ring 6 are connected in series between the two first gaskets 2 .

[0019] Further, several eccentric rings 4 and rubber rings 5 are respectively provided on both sides of the second gasket 3 .

[0020] Further, two or more needle punching rings 6 are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com